The Armenian agricultural market has recently seen a sharp increase in demand for high-quality phosphate fertilizers. More and more local enterprises and investors are actively seeking our consultation on the design of GSSP fertilizer production line through various channels. We recently received a detailed request from an Armenian client. The client wants to create a production line for the production of superphosphate fertilizers with a capacity of 100 000 tons per year, to meet urgent domestic demand for environmentally friendly and efficient fertilizers. To meet this need, we have developed a highly efficient and intelligent GSSP fertilizer production line solution for our customers. This will help them become more competitive in the market and achieve sustainable development. If you are interested investments in the production of GSSP fertilizers, Please, Contact us for consultation!

Get an individual solution !

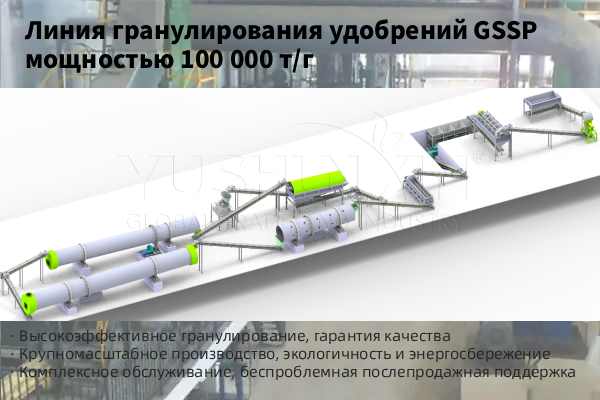

Main technological features of the production line for the production of GSSP fertilizers for an Armenian customer.

| Raw material processing system: | Highly efficient phosphate ore crusher. In combination with multi-stage sifting, a uniform particle size of raw materials is achieved, which is favorable for subsequent acid hydrolysis. |

| Acid hydrolysis process: | A reaction vessel made of corrosion-resistant stainless steel is used. Automated acid addition and precise temperature and time control ensure sufficient reaction between phosphate ore and sulfuric acid, increasing GSSP conversion rate. |

| Granulation and drying process: | Design highly efficient drum granulator and energy-saving rotary dryer. Provide dual control over product particle size and moisture content. Improve the appearance and performance of GSSP fertilizers. |

| Wastewater treatment system for environmental protection: | Equipped with a multi-stage exhaust gas absorption system and a device for recirculating waste fluid. Exhaust gas emissions and wastewater treatment comply with Armenian and European standards, demonstrating a high level of environmental friendliness of production. |

| Automation and intelligent control: | The entire line is equipped with an automated control system based on PLK. Provides remote monitoring, data analysis and one-button control. Significantly reduce labor costs. Improve management efficiency and safety. |

How the GSSP fertilizer production line currently operates at an Armenian customer?

- Stable annual production volume: The annual production capacity of GSSP fertilizer reaches 100 000 ton. The product is in wide demand in the market.

- Stable phosphorus content: The total phosphorus content of the product is ≥16%, which fully complies with international and Armenian national standards.

- Significant energy savings and emissions reduction: Compared with traditional GSSP production lines, energy consumption reduced by 15%. All emission values met standards.

- Intelligent Control: The production line is largely automated. Equipment maintenance simplified. Operational efficiency has increased significantly.

A client from Armenia highly appreciated the GSSP fertilizer production line we supplied.

The client noted, that the GSSP fertilizer production line has a scientifically sound and rational design, works stably and meets environmental standards. This significantly increased the company's competitiveness in the market. Thanks to high-quality GSSP products, the company has opened markets in Armenia and neighboring countries. Expected, that production capacity will continue to expand over the next three years.

If you are looking for a reliable and efficient GSSP fertilizer production line, Please, Contact us. We have extensive industry experience and professional technical team. They can develop the optimal production line solution according to your actual needs. Helping your business stand out in a tough market. Contact our experts by email now, to receive a detailed quote and personalized technical support.

——SHUNXIN 24*7 Fast response. We offer solutions for you!

Get solutions for organic fertilizer production lines or equipment prices!