The drum granulator is a high -performance granular equipment. It is widely used in the production of organic fertilizers, complex fertilizers are low, medium and high concentration, granulations of ore and other industries. If you have needs, Please, Contact us to get additional information.

The parameters of the drum granulator

- Power: 5,5 – 37 kW

- The size of the particles: 3 – 6 mm

- The degree of granulation: 90% +

- Production capacity: 1 – 30 t/h.

- The size of the particles of raw materials before granulation: 50 oven.

- Moisture content of raw materials before granulation: 20% – 40%

- Equipment material: Carbon steel Q235, Rubber material lining

- Application: manure animals, The remains of biogas, humus, brown coal, NPK, bentonite, Mineral fertilizers…

Our Drum granulator uses the process of wet granulation. He can satisfy the needs of cold and hot granulation. The rotating cylinder makes materials roll and collide under the influence of gravity and centrifugal force. Small particles gradually stick together, forming larger spherical particles. Not only increases production efficiency, but also provides uniformity and strength of particles. The largest model of this equipment for granulizing organic fertilizers has production capacity before 30 tons in time. One granulator can satisfy your large -scale production needs. Prices vary from 1000 to 7000 US dollars. If you are interested in buying or you need additional information, Please, Contact us. We will provide you with the best service and support.

Our granulation method in the drum granulator is presented for your understanding.

A drum granulator uses a roller for effective granulation of materials. You will submit powdered or fine -grained materials for granularity to the drum through the feeder. In the drum, small particles of the material continue to rotate and roll under the influence of gravity and centrifugal force. Gradually stick to other materials, forming larger spherical particles. During installation, the drum granulator has a certain angle of inclination. This can lead to the movement and unloading of qualified granular fertilizers in the direction of the unloading port.

In some cases, you may need to add the required amount of wetting agent or glue through the sprinkler system. For example, The humidity of your material does not meet the requirements of granulation. Contribute to the formation and adhesion of particles. Particle size can be controlled, adjusting such parameters, as a drum speed and feed volume. This granulation method is highly performance, homogeneous particles and a wide range of application. Especially suitable for your needs for large -scale production of granular fertilizers.

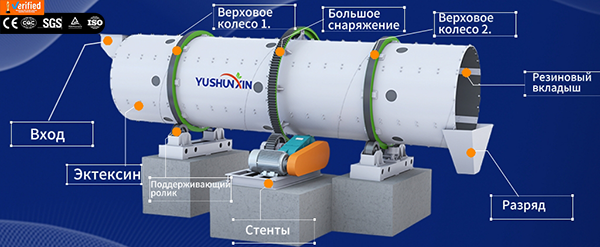

Structural components of our drum granulator.

The composition of our drum granulator includes the following key components. Each part has its own specific function. These components work together, allowing the drum granulator to effectively convert powdered materials into homogeneous granular products. It can be widely used in various industrial production and production of granules of organic fertilizers.

The principled diagram of the units of the drum granulator.

- Port of feed: This is the entrance, through which the materials fall into the drum granulator. It is usually located above one end of the drum, To facilitate the continuous presentation of materials.

- Rubber lining. The inside of the drum is usually covered with a rubber lining. It is mainly used to protect the internal wall of the drum and reduce wear. This can extend the service life of the equipment and improve the effect of granulation.

- Drum: The main part of the drum granulator has a cylindrical shape. The engine sets the gear, which leads to rotation the drum. This is the main place to gran the material. The rotation of the drum makes the material form particles inside.

- Stretch video: used to support and direction the drum rotation. Make sure, that the drum remains stable during rotation.

- bracket: The main design of the entire granulator, used to support and fix the drum and other components. Ensure the stability and safety of equipment.

- Big gears: located in the middle of the outside of the drum. By grunting with a drive device (usually an electric motor and gearbox) She sets in motion the rotation of the drum.

- Video clip 1 And the video 2. Like rollers, These wheels are used for additional drum support. Helps distribute the weight of the granulator and ensures a smooth rotation of the drum.

- Partition: installed inside the drum for control and direction of the flow of materials. Do not allow too fast the passage of materials inside the drum. Make sure, that the material can be completely turned off and formed in a gap-granulator.

- Dispersing hole: This is the exhaust hole, through which granular finished particles are removed from the drum. It is usually placed at the other end of the drum, On the contrary to the position of the port. Convenient unloading particles of organic fertilizers.

Equipment parameters of drum granulator

| Type | Power | In diameter (mm) | Length (mm) | Mounting angle | Rotation speed (rpm) | Performance (t/h) |

| SXZGZ-1240 | 5,5 | 1200 | 4000 | 2-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17,5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5° | 11,5 | 5-8 |

| SXZGZ-2080 | 18,5 | 2000 | 8000 | 2-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5° | 9,5 | 15-30 |

How much do you need to spend on equipment to buy one of our drum granulators?

Prices for the drum granulators sold by us vary from 1000 to 7000 US dollars. Specific prices vary depending on various configurations and requirements for the client model. Among the drum granulators at the same price in the market. Our drum granulation equipment is distinguished by the best quality and advanced production technologies. Always your best choice.

Our process of producing drum granulators!

Our drum granulator uses a lining of acid -resistant and corrosion -resistant stainless steel or rubber lining. This high -quality material can effectively resist erosion, caused by various corrosive materials. Significantly increases the durability and life of the equipment. You can use it in various harsh working conditions.

To process steel, we use modern equipment for the final processing of steel. For example, GIBROY TRAINS, fully automatic machines for laser cutting and t. e. These devices provide the possibility of high -precision processing. Make sure, that the size and shape of each component meet your design requirements. Thanks to the use of this high -precision equipment, we can minimize production errors. This guarantees, that each unit of the drum granulator of equipment meets the highest quality standards.

As for the production process, We use the full process Welding. Conducted by engineers with more than 30 years of experience in welding. Provide the general strength of the structure and tightness of the equipment. After the welding is completed, we will also conduct numerous tests. Avoid any possible problems with leaks. Increased stability and reliability of equipment.

Thanks to the use of these high -quality materials and advanced production processes. Our drum granulators are distinguished by outstanding characteristics in terms of stability, durability and effectiveness. It has an extremely high cost in the market. Chosen by many buyers. No matter, Do you use it to produce small business or for large industrial applications. I'm sure, that this device will provide you with excellent performance and significant investment payback. Welcome, Contact us, To order.

What production situation is suitable for you to use the drum granulator?

On our factory There is a wide selection of equipment for granulizing organic fertilizers. For example, disc granulator, Roller granulator, Granulator of new organic fertilizers and t. e. So, under what circumstances it is advisable for you to use a drum granulator? And not other types of granulators.

- Large production. The granulator drum has high production capacity from 1 to 30 t/h. Suitable for factories, requiring continuous and mass production. This equipment for granulation can process large volumes of material in a short time. It can be done continuously, and it is extremely effective.

- Wide range of particles. If your production requirements are related to particles of different sizes. Then you can use our drum type granulator. He can flexibly reach the production of particles of different sizes, By adjusting the working parameters (such as the speed of rotation, Tilt angle and t. e in.).

- Various types of materials. The granulator drum is suitable for many types of materials. Including organic fertilizers, Chemical fertilizers, Mineral materials and other powdered or granular materials. It has strong adaptability.

- High uniformity and stability are required. The granulator drum is capable of producing granules of a homogeneous shape and a stable structure. If you need uniformity in your product, He can provide it.

- Requirements for humid granulation. If your production process requires the addition of fluid (For example, water or binder) for wet granulation. Drum granulator is the perfect choice, since it can effectively process materials, a certain amount of moisture.

Four methods, which will help you control the size of organic fertilizer particles, produced by the drum granulator!

Our drum granulator can produce for you granules of organic fertilizers with different particles. Optimizing the parameters of your granulator, You can accurately control the size of the granules. Correspond to your specific production needs and quality standards. You can experiment, To determine the best combination of parameters, Based on the specific properties of the material and production purposes. Below are four solutions to optimize parameters, which we provide to you:

Variant 1: The speed of the drum

Rotation speed is an important factor, affecting particle size. Higher rotation speeds usually lead to the formation of smaller particles. Since the material is subjected to a stronger centrifugal force in the drum, It is easier to break it. Lower speed leads to the formation of particles of a larger size. Since the materials remain longer, there are more opportunities to clarify with each other.

Variant 2: The angle of inclination

The angle of inclination of the drum is influenced by the stay of the material inside the granulator. An increase in the angle of inclination will accelerate the flow rate of materials and reduce the stay time. This leads to the formation of smaller particles. Reducing the angle of inclination can increase the time of stay and help form larger particles.

Variant 3: The speed of feed

The feed speed will control the loading of the material into the drum. Lower feed speeds usually lead to that, that the material remains longer inside the drum. This contributes to the growth of particles and the formation of larger particles. Fast feed can lead to that, that the material will not be fully formed on time, which will lead to the formation of smaller particles.

Variant 4: The amount of fluid added

The amount of fluid added (For example, water or binder) directly affects the agglomeration and strength of particles. An increase in the amount of fluid usually contributes to the gluing and growth of particles. However, too much liquid can lead to that, that particles will become too wet and unstable. A decrease in the amount of liquid leads to the formation of smaller and dry particles.

What will you do with granules of organic fertilizers, produced by a drum granulator and not meeting your requirements?

Our current drum granulator has a degree of granulation approximately 70%+. In the production process, the emergence of particles and illiterated powders is inevitable, not complies with your requirements in size. To do this, you can use equipment screening equipment, to separate unskilled particles, which are too large or too small. Then it is transported to the front crusher along the tape conveyor for crushing. Perform and granulation. Make sure, that resources are used completely. We help you reduce waste and increase performance. If you need more detailed optimization solutions, Please, Contact us.

Get the price for this equipment !

Shunxin,Your best partner!

Our products are not limited to drum granulators, but also includes a variety of other equipment for the production of organic fertilizers. You can choose Self -propelled composters, suitable for composting operations of any size. Fermentation containers for organic fertilizers Provide effective solutions for enzyme. Two -vault granulator to meet the requirements of a constant particle size. Fertilizer dryers provide the necessary level of product humidity. Besides, We also We provide additional equipment, such as packaging machines and pallettizers, which will help you implement automatic packaging and staging products. This significantly increases production efficiency and reduces labor costs.

If you have an investment plan for the production line, We can also provide you with a complex Solution for the production of the granulation line of organic fertilizers With a rotating drum. Turning to us, You will receive an individual design solution. Make sure, that your production line achieves optimal results in terms of efficiency and quality. Please, Feel free to contact us, And our professional team will provide you with detailed information about the product and price offer.

Get solutions for organic fertilizer production lines or equipment prices!