A granulator with a ring matrix is a type of equipment, Using the principle of mechanophysical extrusion to transform powdered or fine -grained raw materials into homogeneous particles.

Parameters of the granulator with the ring matrix

- Power: 37 kW

- The size of the particles: 1,5 – 12 mm

- The degree of granulation: 95% +

- Production capacity: 1 – 6 t/h.

- The size of the particles of raw materials before granulation: 50 oven.

- Moisture content of raw materials before granulation: 8% – 10%

- Equipment material: Carbon steel Q235, alloy alloy

- Application: Large, Medium and small aquaculture enterprises, Cereal feed processing plants, Livestock farms, Poultry farms, individual farmers and small and medium farms, Farmers or large, Middle and small feeding plants ...

It is not limited to processing of individual fertilizers, but also suitable for the production of complex fertilizers, processing of feed and other areas. If you want to produce granules of fertilizers using the process of dry granulation, Equipment for granulum with a ring matrix is a very suitable equipment. It has a compact design, It takes up little space, easy to operate and has low maintenance costs. If you have special requirements for the car for granularity with the ring matrix, Contact us for individual manufacture. Shunxin company seeks to provide you with high -quality equipment.

The basic principles of granulation with a granulator with a ring matrix.

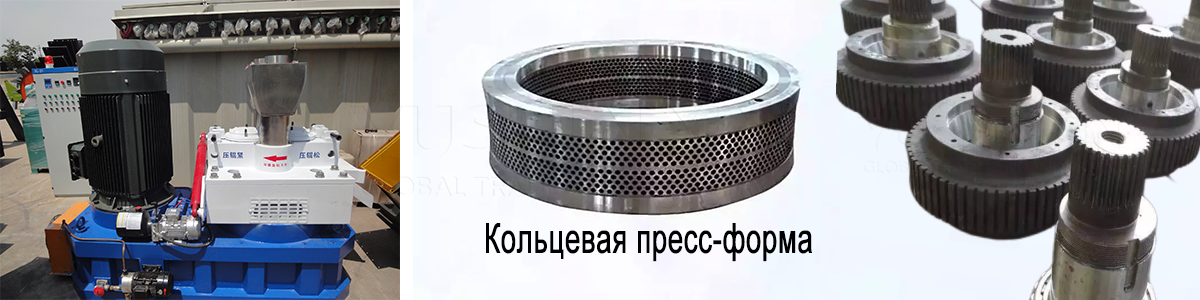

A granulator with a ring matrix is a mechanical device, which forms granules by extrusion of powder materials. After that, how the material enters the granulation zone, It is distributed along the inner surface of the ring filter. The main components of the granulator are the ring matrix and two or more videos. The ring matrix is a ring -shaped steel shape with many holes. The roller is a rotating clamping video, pressure used.

When the granulator is launched, the raw materials are supplied vertically to the granulation bunker. The pressing video automatically rotates at 360 degrees, Squeezing the material into small holes of the ring matrix and forming particles. Then it is squeezed out of the opening of the matrix and passed through the cutting device to obtain a granular product of the required length. This mechanism not only increases the density and strength of the finished product, but also improves the fluidity and processability of the material.

What material do you use for the ring form of our equipment for grancing of ring forms of organic fertilizers?

The ring matrix of our equipment for granulation of organic fertilizers is made of super -legged steel. This material demonstrates excellent wear resistance in conditions of high pressure and abrasive wear and is especially suitable for processing gross and solid materials. Besides, The corrosion resistance of super -legged steel significantly extends the service life of the ring stamp. Retains stability even when working with organic materials, containing caustic components. Its excellent thermal stability allows him to maintain excellent characteristics at high temperatures, granulation arising in the process. The acquisition of our granulator with a ring matrix can reduce the frequency of maintenance of your equipment and the cost of replacing press forms.

Contact us, To find out the price !

What are the advantages to give you the use of a granulator with a ring matrix?

Effective production capacity

The productivity of the granulator with the ring matrix is extremely high. Per hour can be produced before 6 tons of granules of organic fertilizers. This is important for you to satisfy rapidly growing demand for organic fertilizers.

Adjustable pressure

Granulator pressure with the ring matrix can be adjusted, which allows you to process various types of organic materials. Allows granules of the required size and density.

Low energy consumption

Our granulator with a ring matrix is characterized by low energy consumption. Low energy consumption reduces production costs, ensuring the availability of the final product.

Great durability

The granulator with a ring matrix is extremely durable. It has a very strong structure, which allows you to maintain efficient production for a long time. This is a high -profit investment for you.

Under what circumstances will a granulator with a ring matrix suit you?

Our granular equipment is widely used on large, medium and small aquaculture enterprises, Carbon feed processing plants, livestock farms, Poultry farms, In individual farmers, as well as in small and medium farms, farms or on large, medium and small feed processing plants. Effective production capacity makes it very suitable for cases, requiring large -scale production. Thereby satisfying the needs of mass production.

If you want to purchase economical equipment for granulation, You can consider the granular car with the ring matrix. Its high efficiency and low energy consumption increase production efficiency and reduce the cost of production of a unit of production. This is an option with good payback of investments. Help you achieve effective and economical production purposes.

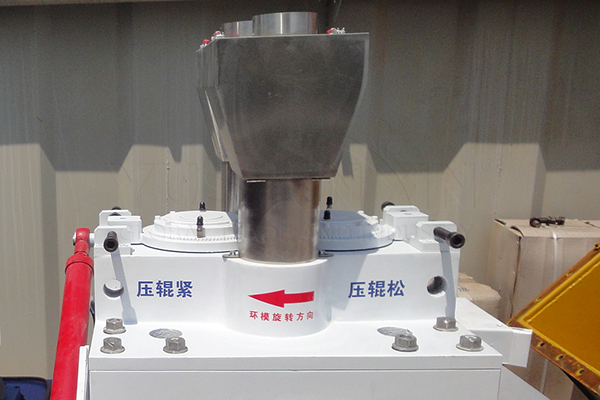

How to adjust the pressure of the granulator rollers with the ring matrix?

Adjusting the pressure of clamping rollers in the granulator with the ring matrix is an important step for ensuring the quality of products and the efficiency of equipment. The pressure is regulated by two screws in the middle storage of the clamping roller. Firstly, You need to have appropriate tools ready and make sure, that the equipment is completely stopped for safe operation. Opening the equipment housing, Loosen the locking device of the propeller propeller. Turning two adjusting screws, located on the middle rack, clockwise or counterclockwise, it is possible to increase or decrease the pressure of the clamping roller accordingly. When adjusting, be sure to rotate two screws evenly, to avoid a deviation of a clamp roller. After completing the adjustment, conduct a test, to confirm the effect of the roller pressure.

What protective devices are our granulator with an annular matrix?

Granulators with a ring matrix are usually equipped with various protective devices, ensuring the safety of operators and extending the service life of equipment. These protective devices work together, ensuring the safety and stability of the production process.

- Overload protection device. When the equipment is subjected to excessive pressure or load, The granulator automatically turns off. In order to avoid damage to the machine or accidents in production.

- Emergency stop button. The emergency stop button is used to immediate stop the machine in an emergency to ensure the safety of operators and equipment.

- Protective covers and protective doors. Do not allow the random touch of operators to moving parts inside the machine.

If you are interested in a granular machine with a ring matrix, Please, Contact us for consultation and purchases. In addition to granulators with a ring matrix, We also offer a variety of equipment for dry granulation, such as Flat matrix granulators And Granulators with two rolls. Satisfy the various needs of your production. Our team will gladly provide you with detailed information about the product and professional technical support. If you have questions or you need additional information, Please, Contact us. We will be happy to provide you with quality products and services!

Get solutions for organic fertilizer production lines or equipment prices!