GSSP is a fertilizer with moderate phosphorus content and an affordable price, widely used in growing various crops. It is distinguished by its wide market specialization and stable customer base.. Investment in GSSP Fertilizer Project Provides These Benefits, how high yield, streamlined production processes and convenient access to raw materials. If you are interested in creating a project for the production of GSSP fertilizers, we can develop a complete solution for you. Contact us anytime, to get detailed information about the investment budget, technological solutions or related equipment. We can provide you various solutions for the production of fertilizers.

Get an individual solution !

What are the technological steps and main equipment, necessary for the production of GSSP fertilizers?

| Process stages | Main equipment | |

| Preparation of Phosphate Ore Powder | Crusher, Raymond Mill, Vibrating Screen, Drum Rumble | |

| Storage and transportation of raw materials | Silos for raw materials, Belt Conveyors, Screw conveyors | |

| Acidolysis reaction | Acid storage tank, Acid resistant dosing pump, Tank for acidolysis, Mixer | |

| Maturation and aging | Maturation chambers/pools, Mixer | |

| Moisturizing granulation | Disc/drum granulator, Spray pump, Injectors | |

| Drying and cooling | Rotary dryer, Air heating furnace, Smoke extractor | |

| Screening and regranulation | Vibrating sieve/drum sieve, Crusher substandard parts | |

| Packaging and environmental protection | Automatic Quantitative Dosing Packaging Machines, Conveyors, bag filters, Acid mist treatment towers, Control cabinets with PLC |

What budget do you need to purchase equipment for the GSSP production line??

The price of GSSP fertilizer production line is not fixed. This requires a comprehensive assessment, based on your planned production capacity, level of automation, environmental protection configuration and brand customization services. We invite you to discuss your specific needs with us to obtain the optimal investment plan for the GSSP fertilizer industry. Helps you maximize productivity and economic benefits. Below are the budget ranges for purchasing equipment for GSSP production line of different sizes for your reference:

- Small GSSP production line (5000–10 000 tons/year): 300 000–500 000 US dollars. Suitable for start-ups or small-scale production. The equipment has a relatively simple design and is mainly semi-automatic.

- Average GSSP production line (10 000–30 000 tons/year): 500 000–1 000 000 US dollars. Suitable for medium size fertilizer plants. The configuration is relatively complete, with a full range of automation and environmental protection equipment.

- Large GSSP production line (more 50 000 tons/year): 1 000 000–2 000 000 US dollars. High level of automation, equipping with intelligent control systems. High production efficiency, a full range of environmental protection products. Suitable for large scale industrial production.

What are the main raw materials you need to prepare in large quantities for the production of GSSP fertilizers?

GSSP fertilizer production mainly uses two types of raw materials:

- Phosphate Ore: choose high quality phosphate ore with low impurity content. This improves product quality and reaction efficiency.

- Sulfuric acid: as a reaction agent it is necessary to use technical sulfuric acid concentration 98% or higher. The quality of sulfuric acid directly affects the completeness and safety of the reaction.

Besides, To ensure process stability, a small amount of water and auxiliary materials is required.

If you are planning to invest in GSSP Fertilizer Production Line, what are the feasibility and benefits of this project?

Market demand is growing steadily:

Phosphorus fertilizers are one of the most important basic fertilizers for agricultural production. Demand for cost-effective phosphate fertilizers is particularly strong in developing countries and emerging markets. GSSP fertilizer offers good value for money and crop adaptability. Demand in sales markets is very stable.

Available raw materials and proven technology:

Raw materials for GSSP fertilizer production are abundant, and procurement channels are diverse. The cost of raw materials is relatively controllable. In this case, the GSSP process has been completed, technology is reliable, and the production process is highly automated. This promotes large-scale production and cost control.

High return on investment:

GSSP production lines can quickly reach production capacity after commissioning. Products are easy to sell, and capital turnover is high. Besides, various by-products, obtained during the production process, expand income channels, which further increases the return on investment.

Ease of localized deep processing:

GSSP fertilizer can be sold as a final product. It can also be used as raw material for high value-added products, such as complex and granular fertilizers. This will make it easier to modernize your product structure and expand your supply chain., thereby increasing your overall profitability.

Comprehensive technical service support:

Currently, both domestic, international companies also have proven technologies and reliable service systems in the field of production equipment and GSSP processes. We can provide you with a comprehensive solution, from plant design and equipment procurement to installation and commissioning. Professional team provides full support, ensuring smooth implementation of the project.

What complex fertilizers can be produced from granular fertilizers, produced on the GSSP fertilizer production line?

Complex NPK fertilizer (nitrogen-phosphorus-potassium complex fertilizer)

- Principle of action: GSSP powders (providing phosphorus), nitrogen fertilizer (For example, urea, ammonium nitrate and ammonium carbonate) and potash fertilizer (For example, potassium chloride and potassium sulfate) mechanically mixed in a certain proportion and granulated to obtain a complex NPK fertilizer.

- Common Recipes: 15-15-15, 17-17-17 etc.. (N-P₂O₅-K₂O content).

- Process: Dry mixing, wet granulation, etc.. e.

BB fertilizer (Bull Blending Fertilizer)

- Principle: GSSP is physically mixed with granular fertilizers, such as nitrogen and potassium fertilizers (no chemical reaction occurs). Specialized mixed fertilizers are produced.

- Peculiarities: Flexible formulations to meet the needs of different crops and soils.

Complex fertilizer, containing trace elements

- Principle: Microelements, such as boron, zinc, iron and manganese, added to NPK or BB complex fertilizer to form a multi-element complex fertilizer.

Organic-inorganic complex fertilizer

- Principle of action: GSSP fertilizer is mixed with organic fertilizers (such as humic acid, animal manure and well-rotted straw) in a certain proportion to form an organic-inorganic complex fertilizer, providing synergistic release of nutrients.

What useful by-products can be obtained from the production of GSSP fertilizer??

The basic principle of GSSP fertilizer production is the reaction of concentrated sulfuric acid with natural phosphate ore. As a result, superphosphate and gypsum are formed. The chemical formula of the reaction is as follows: Ca₃(PO₄)₂ + 2H₂SO₄ + 4H₂O → 2CaSO₄ · 2H₂O + Ca(H₂PO₄)₂.

This reaction can convert insoluble phosphorus from phosphate rock into available phosphorus, easily digestible by crops. This improves fertilizer utilization and promotes plant growth. Various by-products are also formed, such as plaster, hydrofluorosilicic acid, waste heat and dust. All this can bring you economic income.

1. Plaster (phosphogypsum, CaSO₄·2H₂O)

The main reaction of GSSP is the reaction of phosphate ore powder with sulfuric acid, during which insoluble components precipitate in the form of gypsum dihydrate.

Application:

1. Construction materials: can be used for the production of construction plasterboard, gypsum blocks, gypsum plaster, etc.. e.

2. Cement retarder: Used as a retarder in the cement production process.

3. Soil improver: Used to improve alkaline soils, improving their structure and fertility.

4. Calcium sulfate production: For example, for agricultural gypsum.

5. Other branches of the chemical industry: further processing is possible to obtain pure gypsum.

2. Fluorinated by-products(For example, fluorosilicates)

Some phosphate ores contain fluorine. The decomposition of sulfuric acid produces hydrogen fluoride. Further reaction leads to the formation of hydrofluorosilicic acid (H₂SiF₆) or fluorosilicates.

Application:

1. Production of hydrofluorosilicic acid: can be restored, concentrated and sold to external consumers. Used in refrigerants, fluorinated products, etc.. e.

2. Production of fluoride salts: such as sodium fluoride and aluminum fluoride. Used in the aluminum industry and water treatment.

(Note: Fluorosilicic acid and its salts require a special recovery system, otherwise they pollute the air.)

3. Technological queen cell (dilute acid solution)

Phosphorus-containing dilute acid solution, generated in some process streams.

Methods of use:

1. Recycling: return of raw materials to the production system for further use, reduction in raw material consumption.

2. For the production of fertilizers: extract soluble phosphates or process them into fertilizers.

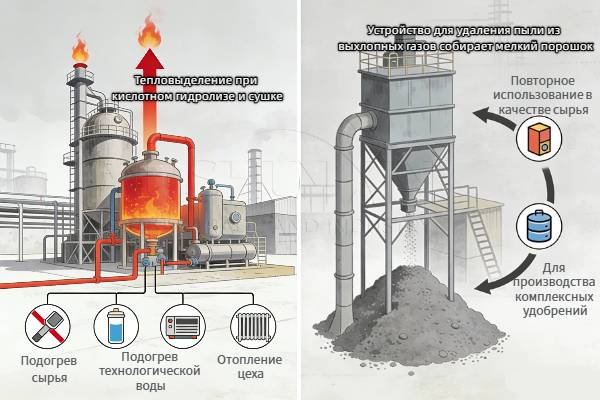

4. Waste heat and residual heat from waste gases

Heat is released during the acidolysis reaction and subsequent drying process.

Usage:

1. Recovery and reuse of waste heat: used to preheat raw materials on the production line, heating process water or workshop heating.

5. By-products of tail gas dust removal

Fine powder (phosphorus-containing dust), captured by tail gas dust removal device.

Disposal:

1. Return to production system: Reuse as raw materials or use in the production of complex fertilizers, etc.. e.

—— Want to learn more about specific cleaning methods, recycling schemes and analysis of the economic value of by-products in the production of fertilizers using the SSP method?

Shunxin is your most reliable investment partner in GSSP Fertilizer Project!

Shunxin Company has been specializing in the production of GSSP fertilizers for many years (granular monoammonium phosphate), having a rich industry experience and advanced technical support. We always adhere to a customer-oriented approach and strive to provide our partners with comprehensive, efficient and professional services. Shunxin will provide full support at every stage of your GSSP fertilizer investment project. This includes scientific project planning, streamlined production processes, strict quality control and constant technological innovation. Ensure the safety of your investments and stable profits.

Interested in investing in the GSSP fertilizer project? Need detailed information about GSSP fertilizer production line cost or process customization? Contact us for customized solutions.

Get solutions for organic fertilizer production lines or equipment prices!