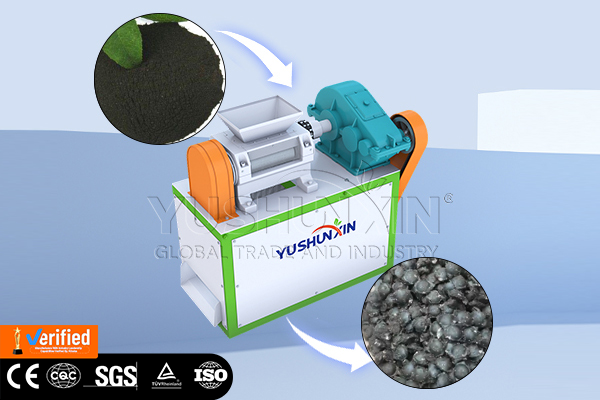

Adjustment density of fertilizer particles, produced by a roller granulator, can be carried out in various ways. We summed up some methods for you. These methods mainly involve the adjustment of the properties of the material, process parameters and equipment settings. The following are some specific adjustment measures:

Get an individual solution !

Correction of the formula of the material:

- The ratio of ingredients: You can change the ratio of ingredients, To increase the content of high density materials. For Increase in particle density.

- Distribution of particles in size: You can also adjust the size of the particles of raw powder. Usually smaller powders help to form denser particles.

- Humidity control: adjust the humidity of the materials correctly. Usually an increase in humidity can increase the density of particles. But too high humidity can lead to that, that particles will become unstable.

Adjustment of technological parameters:

- Pressure setting: You can increase the pressure between the rollers, what can improve the density of particles. Increase particle density.

- Speed control: adjust the speed of the video correctly, to ensure enough compression time of the material.

- Adjustment of the gap: Adjust the gap between the videos. Usually smaller gap increases density particles.

Setting up the configuration of the device:

- The design of the surface of the roller: Choose the right one drawing and material of the surface of the roller, to improve the granulation effect.

- Pre -pressure setting: Add a preliminary pressure device before entering a couple of rollers. This helps to increase the density of the final granula.

- Automated control: Use the advanced automated control system for monitoring and adjusting various parameters of the granulation process in real time. Provide stable pellet quality.

Subsequent processing:

Thanks to the complex setting of the above factors, you can effectively Control the density of fertilizer particles, produced by a two -wound granulator. Satisfy your various production needs and product standards. When making these adjustments, you need to experiment and optimize, Based on your specific production conditions and goals. Requirements for each material and production are different, Therefore, they must be appropriately adjusted and optimized. Find the best combination of parameters. We invite you to visit our factory. We can demonstrate to you these methods on the spot and teach you!

- Drying process: After granulation, excess moisture can be removed during drying. Thereby increasing the density of fertilizer particles.

- Cooling process: The correct cooling process can help particles of fertilizers increase the density and at the same time stabilize.

Get solutions for organic fertilizer production lines or equipment prices!