Recently, a new client joined us: Citizen (nickname), The owner of a large livestock farm in the south of Kazakhstan. He controls several modern poultry farms, Producing millions of broilers and nastek chickens annually. Due to the constant expanding the scale of poultry breeding, the processing of chicken droppings has become a serious problem on the farms. Traditional stacking not only occupies a lot of land, but also becomes a source of unpleasant odor, pest flies and even pollutes water sources. This affects the environment and the life of local residents. At the same time, such problems, as an increase in prices for local fertilizers and deterioration of soil quality, Local agriculture is also worried.

Based on the above situation, The customer began to think about that, how to use a large amount of chicken droppings, produced by poultry farm. This helps to reduce the load on the environment. At the same time, this can increase the additional income of customer farms and contribute to the green development of surrounding agricultural land. After a visit and communication with several equipment suppliers, it I decided to purchase equipment for the production of organic fertilizers our company. Invest in the construction of a modern processing plant for chicken droppings, to achieve harmless, resource -saving and industrial processing of litter.

Get an individual solution !

Below is a brief introduction to the process of smooth implementation of the project of our client from Kazakhstan for you.

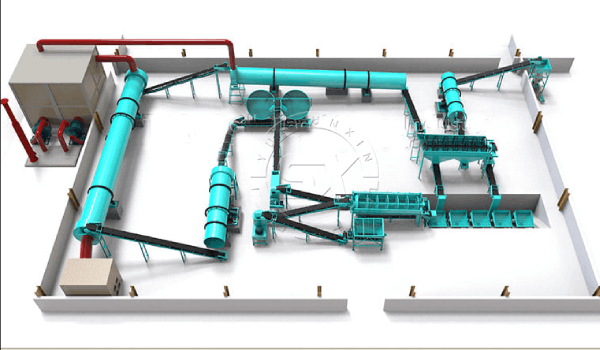

After that, How the customer signed an agreement with our company for the purchase of equipment and its maintenance, The parties formed a special docking brigade. Our technical team first developed a comprehensive construction plan for the processing of the litter, Based on the annual production of the chicken litter, site area and alleged production capacity. The plan included a section of the fermentation of raw materials, The system of turning the material, Workshop of crushing and granulation of organic fertilizers, Packaging workshop, as well as cleaning the outgoing gases and wastewater recovery. The construction of the project is divided into four stages. Preparation of infrastructure, Installation and commissioning of equipment, Employee training and experimental production. Full commissioning was completed in just three months.

Some details of the project:

Given low winter temperatures in Kazakhstan, We recommended to our customers highly efficient fermentation vats with insulation systems. It is also equipped with complete line for the production of organic fertilizers. Including deodorage, Turning compost, crushing, granulation, drying, cooling, sifting and automatic packaging. During the production and supply of equipment, our engineers maintained close contact with the customer. Optimize some equipment parameters in accordance with the requirements of the customer. After the arrival of equipment at the plant, our experts went to the facility. They helped with the construction of the foundation, installation of equipment and commissioning. And ensure systematic training of operators. We also conduct systematic training of operators to ensure uninterrupted trial operation of the entire production line.

What are the advantages of technical solutions, developed by us for our customers in Kazakhstan?

Effective fermentation: Using hermetic aerobic enzymatic vats, We reduce the fermentation cycle to 7-10 days. This allows you to completely remove harmful bacteria and eggs of insects from chicken droppings, Preventing secondary pollution.

Intellectual automation: Implement automatic control of the main links and reduce labor costs. Increases production efficiency and product quality stability.

Environmental friendliness: It is equipped with a deodorization and cleaning system for exhaust gases. Effectively controls smells and emissions ammonia, complies with local environmental standards.

Diversification of products: We can flexibly Produce powder and granular organic fertilizers depending on demand. Satisfaction of the needs of various farmers and agricultural crops in fertilizers.

Actual results and reviews about the process of processing chicken droppings, built by the customer in Kazakhstan.

The actual effect of the line for the production of organic fertilizers from chicken droppings:

After starting the project into operation, the daily capacity of the chicken droppings will reach 100 ton. After fermentation, granulations and other processes annually can be made 30 000 tons of high -quality organic fertilizer. The organic fertilizers were tested in authoritative organizations. Nitrogen content, phosphorus, potassium, humic acids and other indicators exceed similar products in the local market. It can be widely used when growing vegetables, fruit trees, wheat and other crops. Some farmers noted, that after using this organic fertilizer, the soil structure has improved significantly, and the yield and quality of the crop at the same time increased.

Get an individual solution and prices !

Customer reviews:

The customer was very pleased with the results of the project. He noted, that the chicken -scale processing plant effectively reduced the load on the environment of the farm, By turning the litter into a valuable resource. It also provides the farm with a stable income from the sale of organic fertilizers. Many neighboring farms and cooperatives also visited this place and met his experience. Some plan to use and promote this model.

If you also have problems with the processing of livestock and bird droppings, construction of the plant processing plant or the purchase of equipment for the production of organic fertilizers, Contact us. We will develop a comprehensive professional solution for you, providing effective and reliable equipment for the production of organic fertilizers, as well as technical support.

Get solutions for organic fertilizer production lines or equipment prices!