When processing livestock manure, no matter, Big is a volume or small, Most people choose a full set of equipment for the line for the production of organic fertilizers. The equipment of the entire production line can produce as powder, and granular fertilizers. Most customers, investing in the line for the production of organic fertilizers with a capacity of 5-6 tons per hour, The following equipment for the production of organic fertilizers will be purchased.

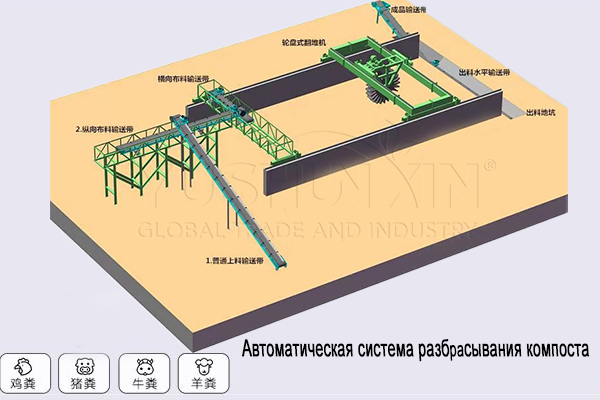

Including dehydrators, Equipment for fermentation, Wheel feeders, crushers of raw materials, Granulators, mixers, sifting cars for powders, drying and cooling machines, coatings, sifting cars for particles, packaging scales and auxiliary equipment, like ribbon conveyors, Machines for rounding particles and t. e. If you need to purchase equipment for the production of organic fertilizers, Contact us.

Get an individual solution !

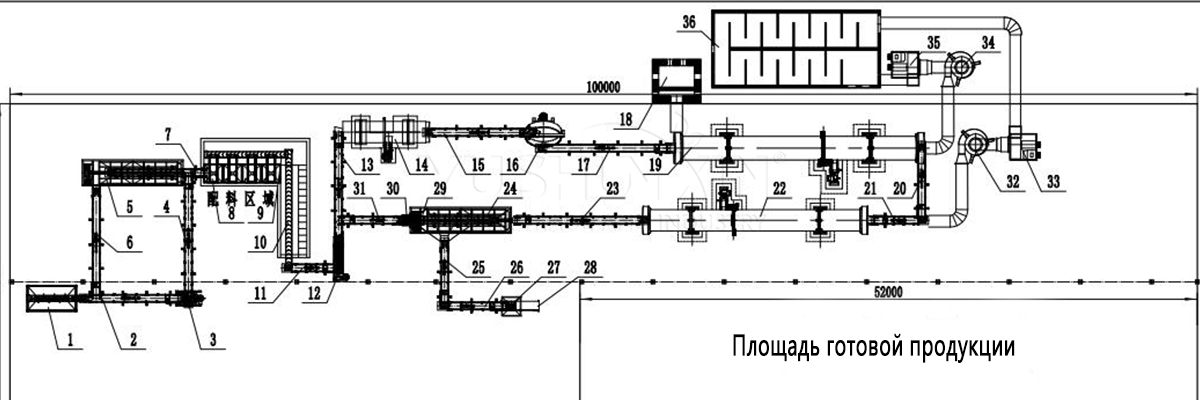

The main production process of the line for the production of organic fertilizers with performance 5-6 tons in time.

One. Fermentation, crushing

The collected droppings and birds will enter the fermentation zone directly. After primary fermentation, Secondary exposure and stacking eliminates the smell of livestock and poultry. At this stage you can add bacteria fermentation for splitting raw fiber. So that the requirements for particles after crushing comply with the requirements for the size of particles for the production of granulation.

Two. Proportion, Mixture

Fermentation materials, The process of secondary exposure and stacking, Grinded. Then enter the mixing and mixing system. Before mixing and mixing, According to the formula, N is added to the mixing and mixing system, P, K and some other trace elements, After which mixing begins.

Three. Granulation, screening,package

Transport mixed materials in granulation system. After that, how granulation passes through the dryer, it gets into the cooling system, which lowers the temperature of the material to normal temperature before sorting. Particles, relevant to the requirements, enter the varnish machine and are wrapped in a film before the packaging. Pellets, Not compliance with the requirements, crushed by a crusher and returned to the granulation system to continue granulation. Finished products are automatically packaged.

Get an individual solution and prices !

Features of the SHUNXIN service:

- Company has its own full production line for granulizing organic fertilizers with a capacity of one ton per hour. You can send raw materials by mail or bring your own, to visit the factory. Our company will conduct raw materials test for you and testing of organic fertilizers.

- The company can provide a free survey of the facility, design, Plant planning and technical management in accordance with your situation.

- The company can design and produce products in accordance with your special requirements.

What services in the field of sales can we provide you?

1. We can send for you technical specialists to plan the foundation line during the manufacture of equipment.

2. The company produces your acquired equipment for the production of organic fertilizers strictly in accordance with current technical standards.

3. After completion of production, we will check the machine for you in accordance with the relevant equipment testing rules, and the products will be strictly checked before sending from the factory.

4. Construction work should be carried out strictly in accordance with the procedures, stipulated by your security system and civilized construction.

The price of a full set of equipment for the production of organic fertilizers with performance 5-6 tons per hour depends on the specific selected equipment. It is recommended to contact us to obtain specific prices and related information.

Get solutions for organic fertilizer production lines or equipment prices!