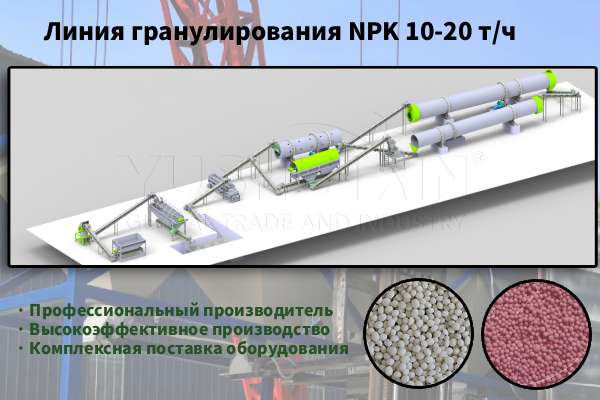

Our solutions for production lines

No matter, Are you a beginner in this area or want to modernize existing production capabilities. We can provide you with professional support. From the initial planning and design of the process to the installation and debugging of equipment, The whole process. Make sure, that each step corresponds to your expectations and production needs. Our team consists of experienced engineers and technicians. They have extensive industry knowledge and can choose the most suitable solution for you. To help you maximize production efficiency and product quality. We are looking forward to your call or letter and we will cooperate with you. Help you produce high -quality organic fertilizers.

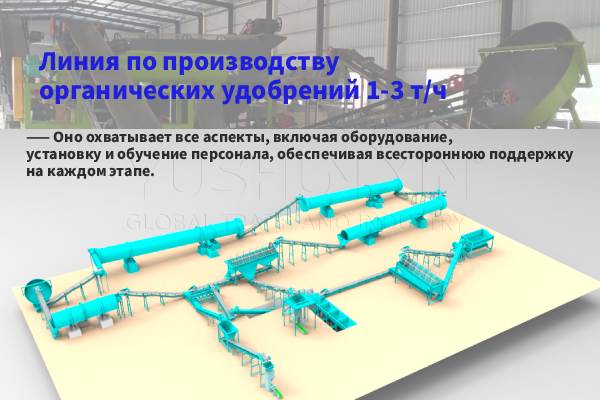

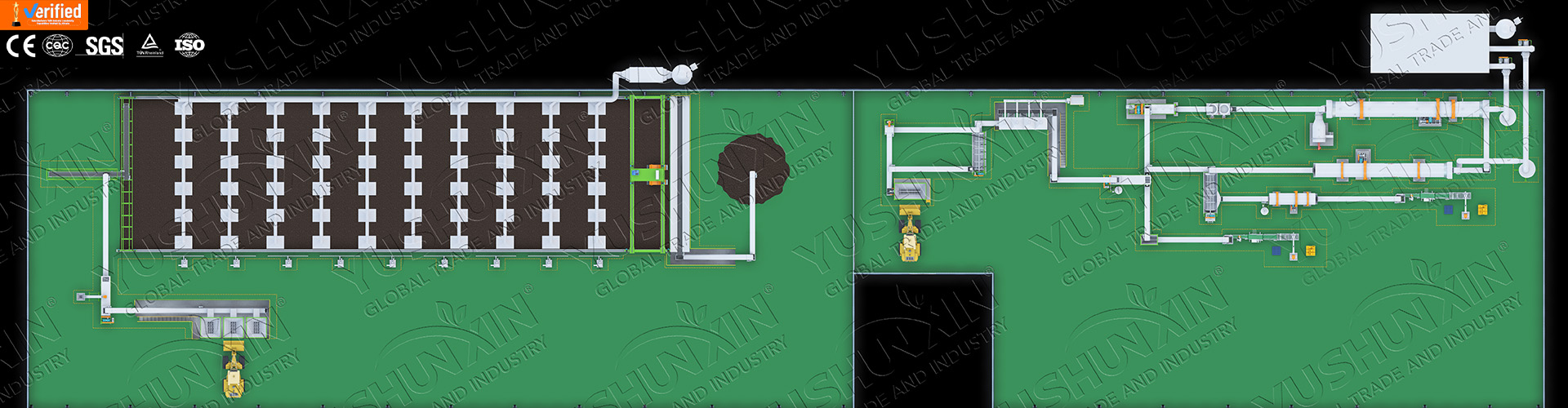

Organic fertilizer production line - Modern solution. It is specially used to effectively transform various organic waste into high -quality organic fertilizers. Our production line is characterized by excellent comprehensive advantages of effective technological power, environmental protection and resource processing. Become the best choice for many customers. We strive to provide each client with complex and high -quality Solutions for the production of organic fertilizers.

Get an individual solution !What equipment for the production of organic fertilizers includes a line for the production of organic fertilizers, which we provide to you?

Our lines for the production of organic fertilizers are equipped with various equipment configurations to satisfy the needs of various production raw materials and the scale of production. For various raw materials, such as cattle manure, straw, Food waste and t. e. We can provide you with individual solutions.

Our team Recommends the best combination of equipment and the technological process, Based on your real needs. Ensuring effective and stable production purposes. We invite you to contact us, To discuss the combination of equipment of the production line to achieve the optimal process of production of organic fertilizers.

Get an individual solution and prices !

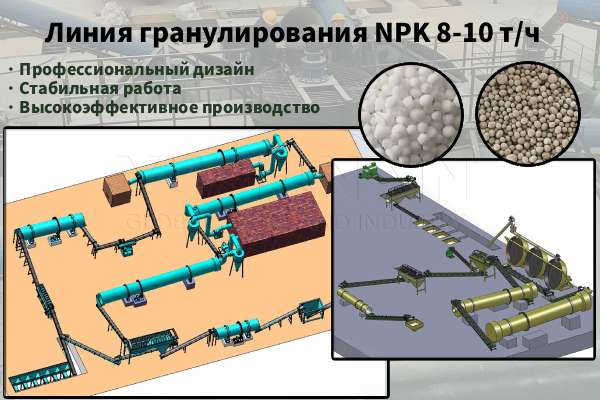

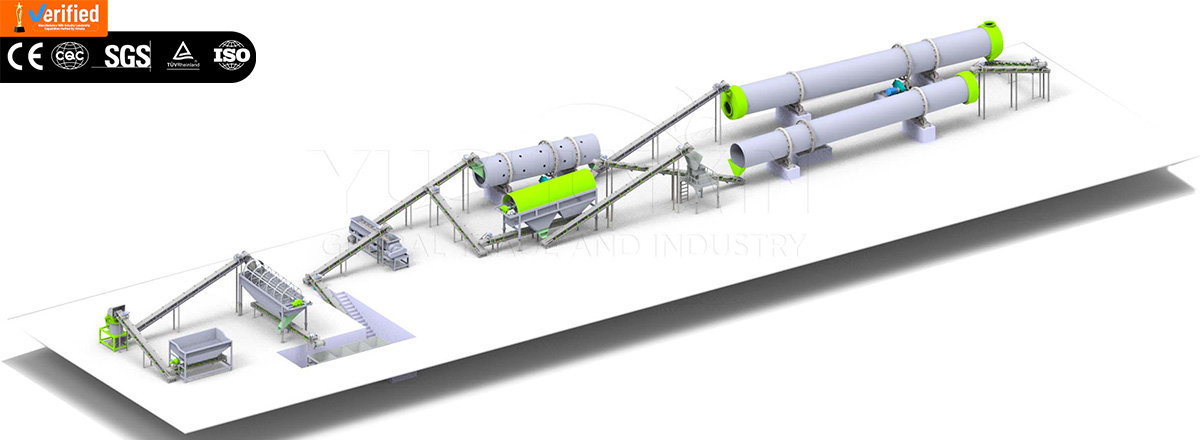

Conventional lines for the production of granular organic fertilizers usually include the following equipment:

- Automatic supply system: Choose the appropriate supply equipment for you in accordance with the configuration of the production line. Provide the continuous supply of raw materials and production efficiency.

- Equipment for preliminary processing of raw materials: including crushers and t. e. For preliminary processing and crushing raw materials. Achieving the correct amount of particles increases the surface area for composting and increases the efficiency of composting.

- Fermentation system: Choose the right one Equipment for fermentation, For example, compost enumber or reservoirs for fermentation. Provide optimal conditions for enzymatic for different parties of raw materials.

- Crusher: Use the grinder, to break agglomered materials after the completion of enzyme. Further decrease in particle size to ensure the uniformity of the material. Convenient for subsequent granulation processing.

- Mixing equipment: completely mix various types of raw materials and additives using a high -performance mixer. Provide the uniform content of nutrients.

- Equipment for granulation: Choose a roller granulator, disk granulator or new granulator of organic fertilizers in accordance with production needs and production process. It will help you make granules of organic fertilizers various specifications.

- Drying system: Use a rotational dryer. Our rotary dryers will help you quickly reduce the moisture content of granules. Improve product quality.

- Cooling equipment: Use a cooling machine to cool the dried particles. Prevent particles sticking and relieve subsequent packaging.

- Equipment for sorting and processing: Separate qualified particles through a sorting machine. They, which do not comply with the standard, Return to the crusher on the strip conveyor to continue processing.

- Coating equipment: Use a coating device, To increase the storage storage storage and fertilizer effect. You can choose various coating materials in accordance with your needs.

- Automatic packaging system. In accordance with the specifications and needs of the product, we provide you with fully automatic automatic packaging machines for quantitative analysis or semi -automatic packaging machines. We help you achieve effective packaging and delivery.

Besides, We also provide appropriate management systems. To facilitate your work and control the working condition of the entire production line.

Get an individual solution and prices !

Our line for the production of organic fertilizers is suitable for which raw materials, which you use for the production of what organic fertilizers?

The line for the production of organic fertilizers is suitable for the processing and production of a variety of organic raw materials. This raw materials are usually rich in organic substances and various nutrients. Suitable for processing into organic fertilizers through fermentation and other processes. Each ingredient has its own special needs for processing and enzyme. Therefore, you need to adjust the parameters of the process in accordance with the characteristics of raw materials in the production process. Ensure the quality and safety of the final product. We provide you with high -quality enzyme equipment. To guarantee optimal processing of various organic raw materials in the process of fermentation. Thereby improving the quality and safety of your organic fertilizers.

Below are some of the most common types of raw materials for organic fertilizers:

- Livestock and bird manure: For example, Chicken manure, Cow navis, Pork manure, Sheep manure, Horse manure and t. e. This raw materials are rich in organic substances and nutrients. However, before using it, it must be fully fermented, To remove microbes and parasite eggs.

- Agricultural waste: Such as straw, Rice husk, Single of cotton seeds, Arachis shell and t. e. These materials must be chopped and fermented. To improve its maturity and fertilizer effectiveness.

- Humic acid: extracted from Slotted coal Or brown coal, is an effective soil air conditioner. This can increase the content of organic substances in the soil and increase microbial activity.

- Food waste: including kitchen waste and waste, Food processing. These waste must properly process, To avoid pollution. Can be transformed into valuable organic fertilizer.

- Municipal waste: Organic parts, such as garden waste, Fruit waste and vegetables and t. e in.. After classification and processing, can be used to produce organic fertilizers.

- Industrial organic waste: such as filter mud of sugar factory, Distillates, Remains Tofu, sawdust, etc.. e. These by -products after processing can be used as raw materials for organic fertilizers.

- Sludge: For example, sediment of city treatment facilities. This raw materials should undergo strict fermentation and harmless processing. To ensure safety and environmental protection.

- Seaweed and aquatic plants: rich in minerals, they can be turned into organic fertilizers through fermentation and other processes.

What investment costs should be taken into account during the construction of a plant for the production of organic fertilizers?

Detailed technical and economic rationale and budget planning are key points, When you plan to build a plant for organic fertilizers. Ensure the rationality of investment and the sustainable development of the project. Professional consulting and design services will help you optimize the investment structure and increase production efficiency. We have many years of experience and helped hundreds of customers to build plants for organic fertilizers. You can contact us to obtain individual decisions.

Below are several aspects of costs, which must be taken into account when creating a plant for the production of organic fertilizers:

The cost of land

Earth is the basis for the construction of a plant for the production of organic fertilizers. The value of the land varies greatly depending on the geographical location and area of the land. Generally speaking, the cost of land in rural areas is relatively low. In the city or in areas with a convenient transport interchange, the cost is higher.

Purchase of equipment line for the production of organic fertilizers

Equipment line for the production of organic fertilizers is one of the main articles of the cost of building a plant for the production of organic fertilizers. The quality and level of equipment automation directly affect the efficiency of fertilizer production. That's why, When you choose equipment for the production of fertilizers. Be sure to find a strong and experienced manufacturer of equipment for organic fertilizers.

Construction of the plant

Including the construction of factories, Construction of warehouses, construction of office premises and t. e. The choice of building materials and the quality of construction directly affect the service life and safety of the plant.

Environmental objects

Factories for the production of organic fertilizers should be equipped with appropriate environmental objects. For example, Equipment for cleaning outlet gases, Equipment for cleaning wastewater and t. e. Investments in these objects are the key to ensuring the compliance of the plant by environmental standards.

Operating costs

Operational costs include the purchase of raw materials, labor costs, energy consumption, maintenance and t. e. These costs continue to arise during the operation of the plant.

How to find a reliable manufacturer when buying equipment line for the production of organic fertilizers?

Acquiring a full set of production lines for the processing of organic fertilizers, Be sure to find a strong manufacturer. The line for the production of organic fertilizers with good quality and productivity of equipment can ensure stable fertilizer processing and effective performance. Below we will share with you some methods of choosing equipment manufacturers for organic fertilizers.

Multiple comparisons online

The Internet eliminates the restrictions of the geographical distance. When purchasing equipment for organic fertilizer production lines, You can search on the Internet of manufacturers of equipment for organic fertilizers. View the official site, To see customer examples, Production equipment and t. d. have a general idea of the company. Look at several manufacturers of equipment for organic fertilizers and compare them. Then select several manufacturers for autonomous field checks.

Checking on the site of the manufacturer

For autonomous checks, it depends on the hardware of the manufacturer, Cases of customer service and service relations. Official and powerful manufacturer of organic fertilizer equipment, It has standard large industrial enterprises and modern medium and large processing machines and equipment. There are professional teams of engineers and engineers on research and development, as well as professional technical workers. Read more customer cases. Cases of customers can reflect the strength and honesty of the manufacturer from the side.

SHUNXIN power as a leading manufacturer of equipment for the production of fertilizers!

Yushunxin - manufacturer of equipment for the production of organic fertilizers. It is located here 40 000 square meters of standardized industrial enterprises of high capacity. At the same time, modern large and average gold processing equipment was introduced, corresponding to international standards. They include 10 processing centers, 3 laser cutting machine and a total of more 80 units of various equipment. This provides a reliable guarantee of the quality of products and development of the company. The full process of after -sales maintenance and technical support will help to solve problems, arising from the use of equipment.

Get an individual solution and prices !

As an excellent supplier line for the production of organic fertilizers, Our company is Shunxin, What services can we provide you?

- Our factory has a full line for the production of granular organic fertilizers with performance 1 t/h. You can send your ingredients to the plant by mail. Or bring your raw materials and visit our factory. We can test for you the effect of organic fertilizers on our equipment for free.

- We can provide a free survey of the object, design, Plant planning and technical management in accordance with your situation.

- If you have special requirements. We can design and manufacture equipment for you in accordance with your requirements.

We have a professional team and rich experience. We strive to provide each client with individual solutions for the line for the production of organic fertilizers and equipment for the production of organic fertilizers. Ensure the effectiveness of the production process and excellent product quality. No matter, Are you a beginner in the production of organic fertilizers or an experienced professional in industry. We will be happy to provide you with support and maintenance. Choosing us, You get more, than just equipment and technologies. It is also a reliable long -term partner. Feel free to contact us anytime, to discuss your needs and vision. achieve the goal of sustainable development.

Get solutions for organic fertilizer production lines or equipment prices!