Modern agro-industrial enterprises strive for high productivity and product quality, Therefore, the selection of appropriate equipment becomes a key success factor. 8-10t/h granulation line for NPK fertilizer production is one such solution, which combines reliability, productivity and adaptation to modern technologies. It allows you to organize continuous process for producing granular fertilizers, meeting market standards, and optimize production costs. If you are interested in this equipment, you can contact us for advice now.

Get an individual solution !

What opportunities does the granulation line open to you? 8-10 t/h?

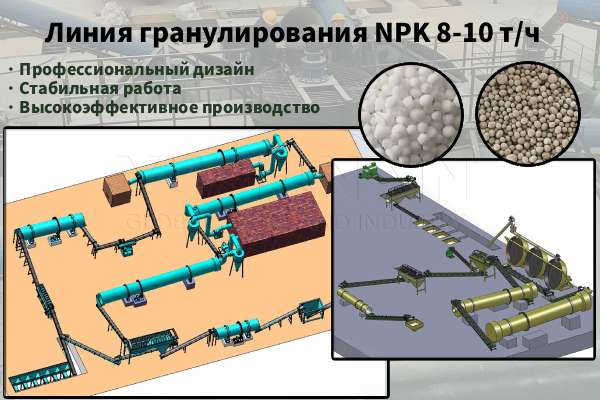

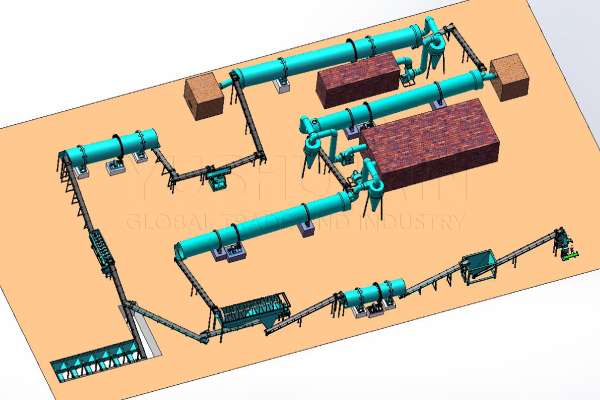

The NPK granulation line 8-10 t/h is designed for the full production cycle of granular NPK fertilizers - from the preparation of raw materials to packaging of finished products. It includes all the necessary components: crushers, mixers, Granulators, dryers and packaging machines (as shown in the presented equipment diagrams). Thanks to this, you do not need to look for individual components and coordinate their work - the complex functions as a single whole.

Besides, this line allows you to adjust the parameters of the granules (size, density) to specific market requirements, which makes your products more competitive. You get the opportunity to increase production volume without losing quality, which directly affects the profitability of your enterprise. Contact us, to learn more about the capabilities of this line.

How the technological process is organized for the NPK 8-10 t/h granulation line?

Process on 8-10 t/h NPK granulation line is divided into several successive stages. Raw materials first (ammonia, phosphoric acid, potassium salts and other components) undergoing training: crushing to the desired fractional composition and mixing in exact proportions. This ensures the stability of the composition of the finished fertilizers.

The mixture is then sent to the granulator, where granules of the desired size are formed. After this, the granules are dried in specialized chambers (as can be seen in the equipment diagrams) to reduce humidity to standard values. The final stage is cooling and packaging of products into transport containers. All stages are automated, therefore, you only need minimal personnel to control the process.

Get solutions for production lines !

What benefits do you get from 8-10 t/h NPK granulation lines?

Automated dosing machines allow precise nitrogen dosing, phosphorus, potassium and other additives according to your recipe.

Another advantage is adaptability. The line can handle various NPK formulations, so you can expand your product range depending on market demand. This makes your business more flexible and resistant to changing competitive conditions. If you want to put these benefits into practice, contact us for a custom offer.

The main advantage of the NPK pelletizing line 8-10 t/h is its productivity: it allows you to receive 8-10 tons of ready-made fertilizers per hour, which meets the needs of medium and large manufacturing enterprises. Besides, equipment is made of high quality materials, therefore it has a long service life and requires minimal maintenance - this reduces operating costs.

How to ensure product quality on NPK 8-10 t/h granulation line?

The quality of finished fertilizers on the 8-10 t/h NPK fertilizer granulation line is controlled at every stage of the process. For this, a modern sensor system is used, which records the parameters of raw materials (composition, humidity), granulation parameters (size, density) and characteristics of finished products. If deviations from standards occur, the system automatically adjusts the operation of the equipment.

Besides, All line components undergo strict quality checks before assembly, therefore the probability of failures is minimal. This guarantees, that your production runs continuously, and the finished fertilizers meet the requirements of state standards and customer wishes.

NPK Granule Production Line 10-12 tons/time, consisting of 8 twin roll granulators.

How to optimize production costs using an 8-10 t/h NPK fertilizer granulation line?

NPK pelletizing line 8-10 t/h allows you to optimize costs in several areas. Firstly, automation of the process reduces labor consumption - a few operators are enough to control the operation of the entire line. Secondly, high productivity allows you to distribute fixed costs (For example, premises rental, energy) for a larger volume of products, which reduces the cost of each ton.

Besides, minimal maintenance and long equipment life reduces repair and replacement costs. All this makes fertilizer production more economical and profitable. If you want to know, how exactly this line will help you reduce costs, consult us.

How to choose and buy a fertilizer granulation line NPK 8-10 t/h?

When choosing an NPK 8-10t/h granulation line, you need to consider several factors: production capabilities of your enterprise (room area, power grid), product requirements (assortment NPK, pellet parameters) and budget. A professional manufacturer will help you choose the best option, adapted to your conditions.

The purchase of a line includes not only the supply of equipment, but also its installation, launch, personnel training and warranty service. This allows you to quickly organize production and start making profits in a short time. Professional Fertilizer Equipment Manufacturer - Yushunxin - leader in this field, so you can be confident in the quality and reliability of the proposed solution.

Get an individual solution and prices !

Rotating drum line for granulating complex fertilizers 10 T/hour

Today, successful production of NPK fertilizers is impossible without modern, productive and reliable equipment. The NPK 8-10 t/h granulation line is just such a solution.: it combines high performance, product quality, cost optimization and market adaptability. As shown in the diagrams shown, it is a complex set of nodes, working in the same rhythm, which guarantees process continuity.

We are an experienced manufacturer, which has great experience in equipping agro-industrial enterprises. Our equipment goes through all stages of quality control, and we also offer an individual approach to each client: from consultation and line selection to installation and after-sales service. If you want to improve your production efficiency, contact us for advice or purchase - we are ready to develop an individual solution for you, tailored to your needs.

Get solutions for organic fertilizer production lines or equipment prices!