Modern agricultural enterprises are increasingly choosing a line for the production of organic fertilizers with productivity 10-20 t/h as a reliable solution for processing raw materials and creating competitive products. This scale allows you to produce large volumes of granular fertilizers, respond quickly to market demand and manage inventory effectively, which provides a stable income. Investment in automated technology guarantees optimization of the production process, reduction in personnel costs, increasing the yield of finished products and improving quality. If you are looking for an economically feasible and technologically advanced solution, be sure to contact us for advice on choosing equipment.

Get an individual solution !

How we help you choose equipment for a modern organic fertilizer production line 10-20 t/h?

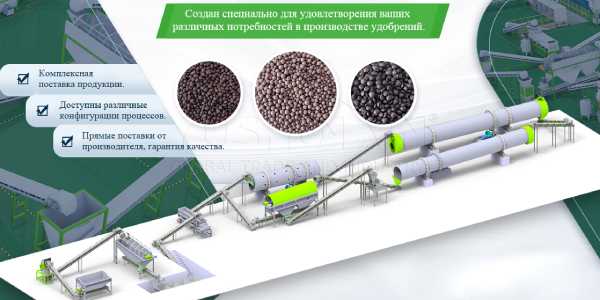

The market for modern solutions requires an integrated approach to organizing the production of organic fertilizers 10-20 t/h. For efficient operation of the line you receive a whole range of equipment, which includes such devices, like a crushing machine, mixing machine, granulator, screening machine, drying and packaging machine. This approach ensures uninterrupted processing of raw materials, its preparation, granulation, drying and packaging. The result is high productivity and consistent product quality.. Modern machines allow you to process a wide range of raw materials, which is especially important when planning industrial volumes.

Get solutions for production lines !

Complete Organic Fertilizer Drum Granulation Line for Sale

What financial investments do you consider when purchasing an organic fertilizer production line? 10-20 t/h?

Cost of a set of equipment for the production of organic fertilizers 10-20 t/h is usually approx. 30 0000 dollars, however, the exact price depends on the specifics of the selected machines and the level of automation. The price includes the costs of the main units, such as crushing machine, granulator, mixing machine, as well as auxiliary devices - drying machine, Packaging machine, dispenser and sifting complex. You should also consider installation costs, staff training, spare parts and subsequent maintenance. This approach allows you to choose the optimal configuration for your business needs., taking into account budget and production needs.

What types of organic fertilizers can you produce with our help??

By using modern line you will be able to produce a wide range of granular organic fertilizers. Depending on the selected raw materials and technology, the line allows the production of composted, dung, peat, vermicompost and complex organic fertilizers. The production process is based on organic granulation, which ensures uniform distribution of nutrients substances, ease of storage and transportation of the final product. You get the opportunity to produce as small, and large granules, as well as pellets, meeting the requirements of the modern market.

In each batch of finished products, granules undergo careful processing: first grinding and mixing the components, then forming granules on a granulating machine, followed by drying, cooling, sifting and packing. This multi-stage processing allows you to obtain consistent quality and high efficiency products..

How can we simplify the process of preparing and dosing raw materials for you??

You get effective solutions for the preliminary preparation of raw materials thanks to the use of such devices, How crushing machine and mixing machine. The crusher allows you to crush organic material to the required fraction, which facilitates further mixing and granulation. Mixing machine ensures uniform distribution of components, which is important for the stable quality of future granules.

If necessary, process automation includes the use dosing machines, who are responsible for the precise feeding and mixing of ingredients. This approach greatly facilitates your control of the production cycle and helps minimize raw material losses.. As a result, all pre-processing steps are completed quickly, efficiently and with minimal time expenditure.

What granulation solutions do we offer you to obtain top-class products??

Our line uses various types of granulators: disc granulator, twin roll extrusion granulator, Drum granulator And flat die granulator. Each granulator is selected based on your size requirements, shape and density of granules. Such machines provide high processing speed, particle uniformity and strength.

Depending on the objectives of your enterprise, the production line can be equipped with additional options - a cooling system, sifting and separating substandard granules. This allows you to obtain granules of different diameters and compositions, and also optimize the process for different types of raw materials. Constant introduction of new granulation technologies guarantees your production, meeting international standards.

Why you should trust us to equip your organic fertilizer production line 10-20 t/h?

Choosing modern equipment, you get a quality guarantee, reliability and fast support. Our engineers develop individual projects to suit your goals, taking into account all the technological nuances. During the cooperation process, you receive detailed consultations, professional support and timely service.

The proposed solutions allow you to scale up your production, introduce new types of products and reduce costs. As a result, you increase business efficiency, and also get the opportunity to expand the range and supply high quality products to any market. If you need advice on packaging, cost calculation or individual projects - you can always contact us. Complete solutions, modern technologies and experience of specialists make your enterprise competitive and promising. Contact us to discuss details, consultations and purchase of individual turnkey lines.

Get solutions for organic fertilizer production lines or equipment prices!