Presenting our advanced equipment for the production line of granulation of organic fertilizers. Equipment is designed for performance 8-10 tons in time. This advanced equipment is developed taking into account the needs of modern agriculture. Provides you with effective and reliable solutions for the production of high -quality organic fertilizers. Would you like to increase production capacity or improve the quality of fertilizer products. Our granulation line of organic fertilizers 8-10 t/h provide excellent performance and excellent results.

Get an individual solution !

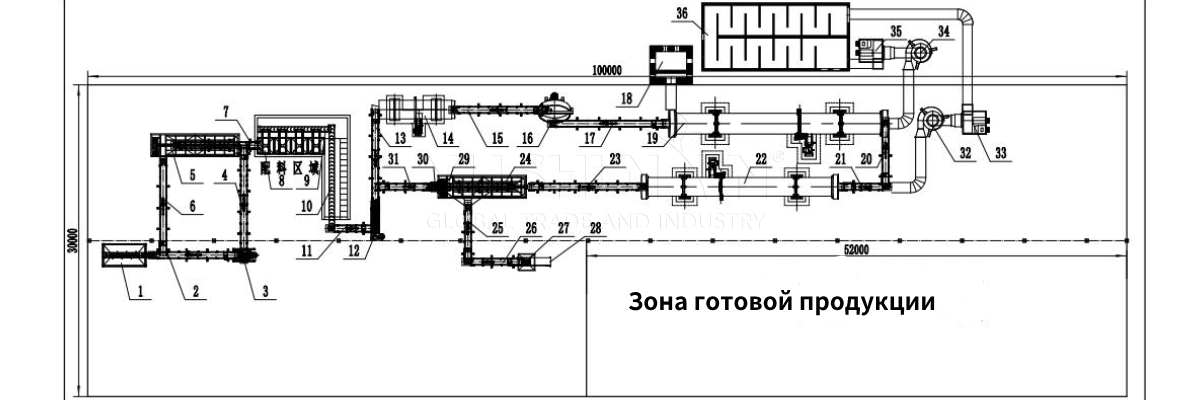

A detailed list of equipment, necessary for the line of granular fertilizers 8-10 t/h.

1. Bunker for feeding the material with a forklift loader in size 2m*4m | 2. Ribbon conveyor type 600 length 9 m | 3. Vertical crusher type 1000 | 4. Type band conveyor 600 length 12 m | 5. Drum sorting machine 1,8*7 m | 6. Type band conveyor 600 length 10 m |

| 7. Ribbon conveyor type 600 length 9 m | 8. 4-x bunker automatic dosing machine | 9. Ribbon conveyor type 600 length 7 m | 10. Type band conveyor 600 length 10 m | 11. Type band conveyor 600 length 5 m | 12. Twin shaft mixer type 3 m |

| 13. Type band conveyor 600 length 10 m | 14. A granulator with a rotating drum 1,8*7 m. | 15. Type band conveyor 600 length 10 m | 16. Tarelly granulator type 3000 | 17. Ribbon conveyor type 600 length 12 m | 18. Hot air |

| 19. Drying machine 2*20m | 20. Ribbon conveyor type 600 length 7 m | 21. Type band conveyor 600 length 5 m | 22. Cooling machine 1,8*18 m | 23. Ribbon conveyor type 600 length 12 m | 24. Drummer roar 1.8n*7m |

| 25. Type band conveyor 600 length 6 m | 26. Type band conveyor 600 length 6 m | 27. Warehouse of finished products 1500*1500 | 28. Libra for packing granules with bunker | 29. Ribbon conveyor type 600 length 9 m | 30. 600 Chain crusher |

| 31. Ribbon conveyor type 600 length 6 m | 32. Cyclone pollen 1800 | 33. 8With an exhaust fan | 34. Cyclone dustproof type 1800 | 35. 10With an exhaust fan | 36. Dust room |

What is the technological process of the granulation line of organic fertilizers with performance 8-10 tons in time?

The design of this production line includes several processes for you. The process of crushing, Mixing process, Transportation process, The process of granulation, drying and cooling process, Sifting process, Coating process and packaging process. Equipment, which you can use for each process, and the characteristics of the equipment are the following:

1. The process of crushing

You can use new type of crusher of a half -habitable material. It combines the characteristics of a vertical crusher and a horizontal crusher. There are two types of internal structures: chain type and hammer type there is no sieve, Therefore, even if the material is removed from the water and chop, it will not be clogged.

2. Mixing process

Mixers Our factory includes vertical mixers, Horizontal mixers, Twarvial high -power mixers, drum mixers and t. e. The internal structure of mixing is divided into the type of lobed mixing, spiral type and t. e. You can design a suitable mixing structure in accordance with the characteristics of the material. The final hole is designed to control the cylinder and control the partition.

3. The process of granulation

You can choose granulator specifically for organic fertilizers. Granulators, which can provide you with our factory, Turn on the disc granulator, New wet granulator, The rugging machine, Drum granulator, coating machine and t. e. Depending on the characteristics of raw materials, select the granulator, appropriate.

4. Transportation process

Ribbon conveyors include mobile strip conveyors, Stationary strip conveyors and t. e. Ribbon conveyors are economical logistics conveyor equipment, which is indispensable for rhythmic assembly lines. It has high transportation productivity and a large transportation distance. The design is simple and convenient to maintain. It has many functions, which allow you to easily implement software control and automatic work.

5. Drying and cooling process

A rotating dryer is also known as a drum dryer, Biological dryer for organic fertilizers. Since the temperature of organic fertilizers during drying cannot exceed 80 °, Our dryer uses drying mode with hot air. Cooler - looks like a dryer in appearance, but differs in material and performance. The main frame of the dryer is made of boiler room. The main frame of the cooler is made of a plate from carbon steel.

Contact us, To find out the price !

6. Sifting process

Conventional sifting machines include drum and vibrational type. Besides, Sifting machines can be divided into three -stage, Two -stage, etc.. e.

7. Coating process

Particle coating machine – The main engine looks like a dryer and cooler. But the internal structure is very different. The inside of the car for applying the film coating is made of sheet stainless steel or lined with polypropylene. The whole machine includes an appropriate powder machine and an oil pump.

8. Packaging process

Automatic dosing packaging machines are divided into spiral type and type DC, with one head and with two heads. Materials - stainless steel and carbon steel. You can configure in accordance with your actual needs.

When designing and setting up a production line, the appropriate equipment should be selected in accordance with specific production needs, characteristics of raw materials and conditions on the spot. And ensure uninterrupted connection and effective work between devices. To ensure the uninterrupted operation of the production line, we recommend that you cooperate with professional equipment suppliers. Get individual solutions and technical support.

Shunxin - Professional supplier of fertilizer equipment, guaranteeing you calm.

If you are interested in equipment for a production line of granulum of organic fertilizers 8-10 t/h. Or you need additional technical advice and solutions. Please, Feel free to contact us. Our professional team will provide you with individual services and support to ensure the effective work of your production line.

Get solutions for production lines !

Get solutions for organic fertilizer production lines or equipment prices!