Disposal of chicken manure has become a serious problem for many large poultry farms.. If you have 500 000 belt, you can produce about 40-60 tons of chicken manure every day. The annual production volume can reach more than 15 000 ton. If this litter is not disposed of in time, it can compromise hygiene and pollute the environment. SHUNXIN We are carefully developing a project for the production of organic fertilizers from chicken manure, suitable for large poultry farms. Using advanced bio-fermentation and automated equipment, We efficiently process chicken manure into high quality organic fertilizer. The whole production process is scientific and standardized. It can effectively remove odors, destroy harmful bacteria and ensure the safety and environmental friendliness of fertilizers. Achieve reduction, harmlessness and efficient use of resources. If you have any needs, Please, Contact us. We will provide you with a complete set of equipment, technical support and comprehensive service.

Get an individual solution !

What is the technological process of our organic fertilizer production project, designed to hold up to 500 000 belt?

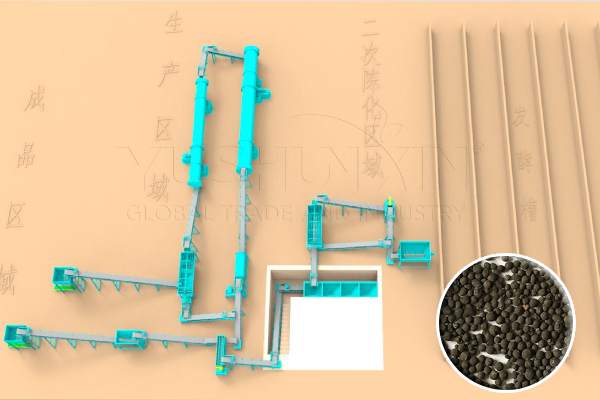

Equipment for producing organic fertilizers from chicken manure on large poultry farms requires a more scientific configuration. This is necessary to promote the use of manure resources and achieve environmentally friendly and efficient development. Our project for the production of organic fertilizers from chicken manure systematically optimizes all production processes. Including pre-treatment, Fermentation, Grinding, mixing, granulation, drying, sifting and packaging. This effectively improves fertilizer quality and production efficiency. We are pleased to offer you a comprehensive solution for organic fertilizer production line.

Get an individual solution and prices !Specific process for producing organic fertilizer from chicken manure:

- Collection of raw materials: centralized collection of chicken manure to remove impurities and foreign particles.

- Solid-liquid separation: use equipment for dehydration of chicken manure, to reduce the humidity to approximately 60% and facilitate fermentation.

- Additional materials: add conditioning materials, Such as straw, sawdust and mushroom waste, depending on the required ratio of carbon and nitrogen.

- High temperature fermentation: use tray type compost turning machines, Armor vats and more aerobic fermentation equipment. Effectively destroys pathogens and insect eggs, promotes composting.

- Secondary maturation: After fermentation, organic fertilizer is stored for a certain time, so that it can completely decompose.

- Screening and crushing: grind and sift composted fertilizer to improve product quality.

- Granulation: use organic fertilizer granulator to obtain granules as needed.

- Drying and cooling: reduce humidity and cool the finished product.

- Packaging and storage: finished organic fertilizer is packaged and stored until sale.

How much does it cost to purchase a complete set of equipment for a line for the production of organic fertilizers from chicken manure??

500 000 chickens are produced annually 15 000 tons of fresh chicken manure, from which you can get about 6000 tons of finished organic fertilizer. This requires production line with a capacity of approx. 8-10 ton granular organic fertilizers per hour. Our chicken manure organic fertilizer production line includes all the above processes and necessary equipment.. The investment in complete equipment is approx. 200 000-280 000 US dollars. At the same time, it is equipped with environmental protection features, such as deodorization and dust removal systems, to ensure odorless production processes and compliance with environmental standards. Besides, we also provide you with comprehensive services. Including process design, selection of equipment, installation and commissioning, staff training and after-sales service.

Our technical team can design the most suitable production plan for you free of charge based on your plant layout and raw material characteristics.. Ensure smooth commissioning and efficient operation of the project. Contact us for custom production.

Contact us, To find out the price !How automated is this line for the production of organic fertilizers from chicken manure??

A highly automated project for the production of organic fertilizers from chicken manure can save you from 80% worries. Moreover, our equipment is designed for 500 000 belt, and only high automation can make it more suitable for large farms. We use PLC (programmable logic controller), which allows everything 1-2 workers to perform simple switching operations to keep the production line running smoothly. In particular, Fully automated organic fertilizer production line includes three controllers, each of which is responsible for a key stage.

The first controller is used for large-scale composting of chicken manure, providing automation of the composting process. The second controller controls a number of main equipment. Including dispenser, chopper, mixer, granulator, dryer, cooler and coating machine, accurately controlling their automated operation. The third controller services the fertilizer packaging system. No matter, whether you choose a semi-automatic or fully automatic packaging system, it regulates such parameters, how is the packing speed. Ensure automation and efficiency of the packaging process.

Get an individual solution and prices !

Common Problems and Solutions for Most Farms, investing in the project for the production of organic fertilizers from chicken manure.

How to deal with excess moisture in raw materials from chicken manure?

- For pre-dehydration to reduce moisture content below 50% Before starting the fermentation process, a solid-liquid separator is used.

- Straw can be added during fermentation for adjustment., sawdust and other auxiliary materials.

- Use a turner to stir the compost regularly during fermentation, to promote water evaporation and uniform fermentation.

How to solve the problem of odor and flies during the fermentation process?

- Choose a closed or semi-closed fermentation process, equipped with biological deodorization equipment or spray deodorization system.

- Add microbial fermenting agents to speed up the decomposition of harmful bacteria and reduce odor.

- Standardize storage and handling of compost, to avoid open storage and long-term accumulation.

What to do, if the finished fertilizer contains more moisture, what is required, or the granules are uneven?

- Equip a special dryer to quickly dry granular organic fertilizer to a safe moisture content (≤20%).

- In the granulation process, granulation equipment should be selected, suitable for the characteristics of chicken manure (For example, disk, drum or Roller granulator).

- Install a sorting and screening system to separate the granules, not meeting the requirements, and return the material for re-pelletization to ensure uniformity of granules.

How to prevent and control secondary contamination during storage and transportation?

- Use automatic packaging and sealing equipment with moisture-proof packaging materials.

- Build a ventilated and dry warehouse and avoid storing goods directly on the ground.

- Regularly check humidity and ventilation in the warehouse to maintain cleanliness.

Choose our large-scale project for the production of organic fertilizers from chicken manure (500 000 belt). This not only effectively solves the problem of environmental pressure, caused by indiscriminate storage of chicken manure during poultry farming, but also creates a new point of economic growth for you. If you would like to learn more about the processes for producing organic fertilizer from chicken manure, investment budget of the project or choice of equipment, Contact us. We are always ready to answer your questions.

Get solutions for organic fertilizer production lines or equipment prices!