NPK - an indispensable type of fertilizer in the modern fertilizer market. Our complex fertilizer production line will help you produce NPK fertilizers, corresponding to market demand. Shunxin Machinery Equipment offers two different solutions for the production of complex fertilizers: NPK granulation line and mixing line NPK granules. Regardless of your budget and that, What production process do you plan to use. We can offer you production solutions, which are suitable for you. If you have special needs, We also support individual services. Welcome, Contact us to get detailed information!

Get an individual solution !

Two high -quality solutions for the production of complex fertilizers are offered to your choice.

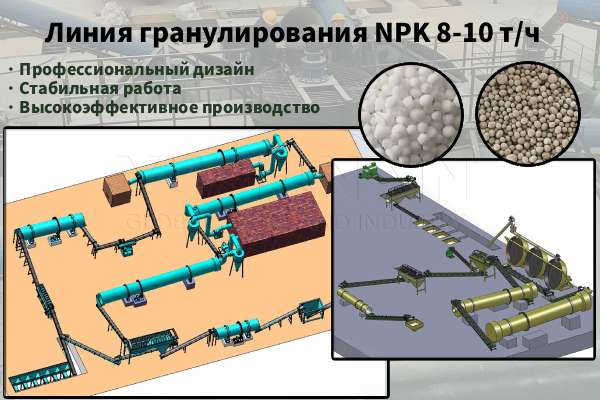

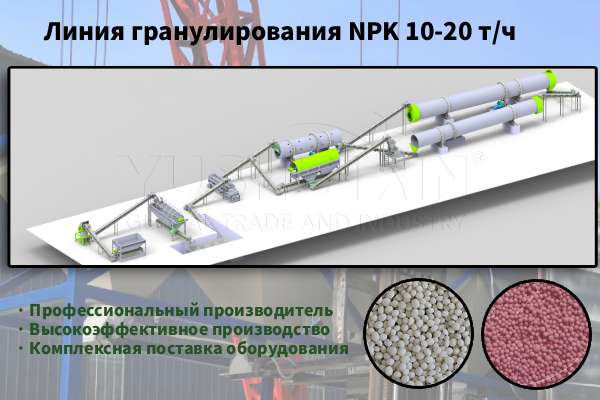

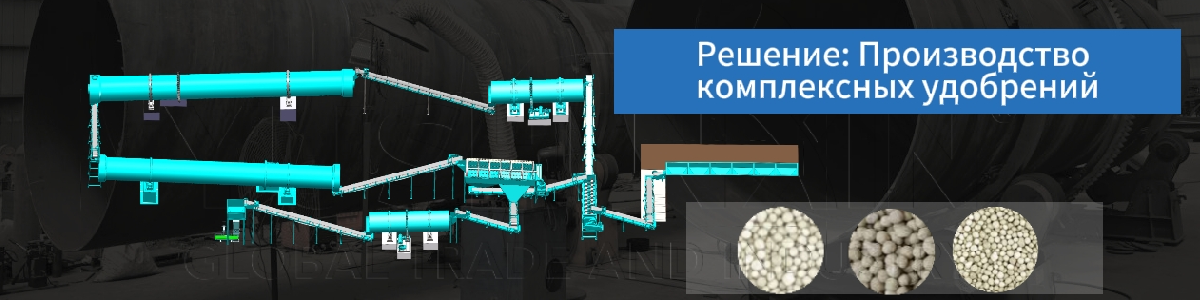

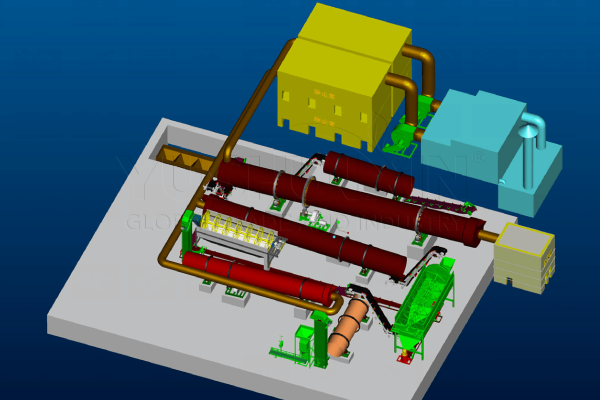

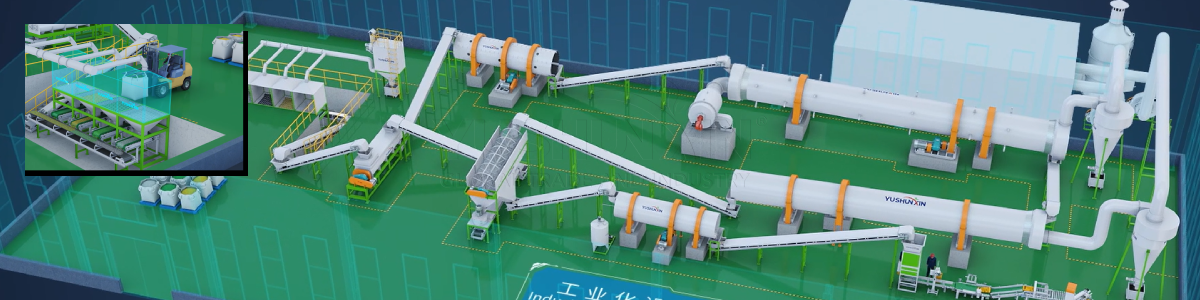

Solution for the line of granulation of complex fertilizers

The granulation line is the main choice for the production of high -quality standardized complex fertilizers. Suitable for large -scale production. The production line covers many links, including preliminary processing of raw materials, Dosage, mixing, granulation, Drying and cooling, screening, Coating and packaging of finished products. Particles of complex fertilizer, granulation, have a uniform shape and stable quality. Automated work reduces your production costs. Many large manufacturers of complex fertilizers around the world are already cooperating with us. Help them make npk fertilizers, corresponding to the needs of the international market.

Get solutions for production lines !

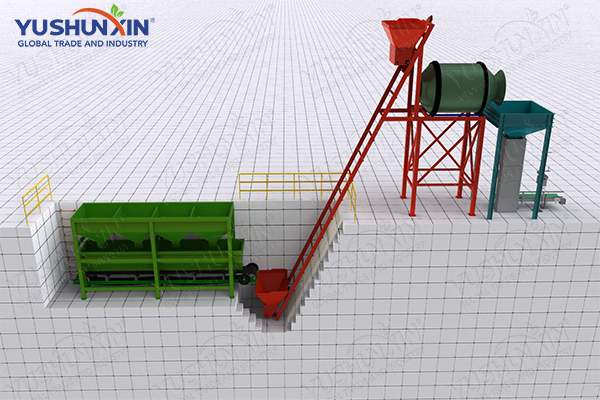

Solution for NPK Granule Mixing Line

The line of mixing granules embankment, also known as a line for the production of complex fertilizers. Known for its flexibility and efficiency, It is especially suitable for small and medium -sized production, as well as to meet the individual needs for setting. The production line mainly consists of a raw materials warehouse, automated dosing, effective mixing and packaging of finished products. The biggest advantage of this production method is, that it allows you to quickly respond to market changes and quickly adjust the formula. Make target special complex fertilizers. The mixing line of bulk materials is characterized by low investment costs, small area occupied and short production cycle. Ideal for small businesses, agricultural cooperatives and supplies to regional markets.

More solutions to produce BB fertilizers with different capacities.

Which production process is more suitable for you for the production of NPK fertilizers?

The choice of a suitable granulation process is a key solution in the production of complex fertilizers. There are two common granulation processes: Wet granulation and dry granulation. You can consider various factors and choose one of them.

Wet granulation process of complex fertilizers

If you want to make your NPK fertilizer more rounded and withstand the test during transportation over long distances. Wet granulation process is your good choice. The process consists in mixing various powdered main raw materials fertilizers with the corresponding amount of water or other liquid additives. Under the influence of external power, ready -made complex particles of fertilizers of a certain roundness are formed. Our Disk granulators And Drummers Perfect for your moist granulation process, Welcome to buy.

Get an individual solution and prices !

Dry granulation process NPK

If your investment budget is not so big, then you can consider the technology of dry granulation. Dry granulation technology practically does not require the use of binders, such as water. Materials with moisture content less 10% can be formed in granules by extrusion. Moreover, Stages of drying and cooling, necessary in the process of wet granulation, not required in the process of dry granulation. What granulation equipment can support this process? Two -wool granulator. This is the most acquired dry granulator.

What equipment will help you improve the quality of ready -made complex fertilizers, which you produce?

In the process, the production of complex fertilizers for joint work requires various equipment. This plays a key role in improving the quality of ready -made complex fertilizers. So, What equipment will help you improve the consistency of the finished fertilizer? The following two types of fertilizers can be used.

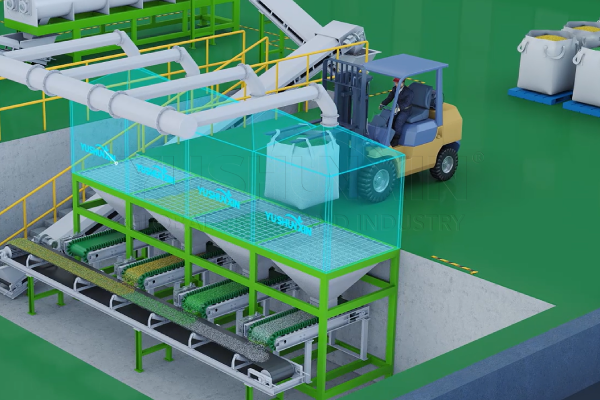

Continuous automatic dosing

Continuous hopper automatic dosing is the main equipment, providing the quality of ready -made fertilizers. Whether it is a line of granulation or a line of mixing bulk granules, She is indispensable. Compared to the traditional method of periodic dosing, A continuing automatic dosing warehouse can provide a 24-hour uninterrupted and stable operation. High -precision sensors and intellectual algorithms, by which he is equipped, allow you to strictly control the error of the ingredients in a very small range. Make sure, that the ratio of nutrients in each batch of finished fertilizer is a stable. We provide a reliable guarantee of the production of high -quality complex fertilizers.

Get the price for this equipment !

Fertilizer mixer BB

In the line of mixing granular fertilizers, the BB fertilizer mixer is key equipment, providing an increase in the uniformity of mixing fertilizers. Inside there are stirring shafts rotating in opposite directions. It can drive the blade, causing strong convection, diffusion and shift movement of materials in Three -dimensional space. Groups of fertilizers of different sizes and specific gravity can be completely mixed in a short time. The homogeneity of mixing can reach more 95%. At the same time, the BB fertilizer mixer is easy to operate and maintain. This can effectively reduce labor costs and maintenance in the production process.

How many workers do you need to hire, to invest in our smallest production line?

For effective operation of the smallest line for the production of complex fertilizers, which we offer, only 3-4 workers are required. Of them 1 The worker is responsible for the raw materials and 1-2 workers are responsible for the operation of equipment. The remaining 1 The employee is responsible for checking, Laying and managing the storage of finished products. Optimized staffing reduces labor costs. Thanks to a clear division of labor and cooperation, we can ensure the effective and stable operation of the production line. Especially suitable for small business and investors in the early stages.

Get solutions for production lines !

When you decide to purchase equipment, what should have a qualified supplier of equipment?

Strong technical R&D and innovative opportunities: Qualified equipment suppliers must have a professional and innovative technical team of R&D. The ability to carefully monitor advanced technologies and development trends in the industry production of complex fertilizers.

Strict product quality control: The quality of the equipment is the cornerstone of stable operation of the production line and product quality. Suppliers need to create a strict quality control system. For production, we use high -quality and reliable raw materials and advanced production processes.

Ideal after -sales service system: Ideal after -sales maintenance is an important guarantee of uninterrupted production of enterprises. Suppliers must provide professional services for the installation and commissioning of equipment into operation. As well as ensure comprehensive and systematic training of enterprise operators.

Get solutions for production lines !

Universal supply of Shunxin equipment gives you peace of mind.

We provide a full service process. From early planning and choice, medium -term installation and training until subsequent maintenance and modernization. Moreover, We always pay attention to the latest technological innovations in the industry. Provide you decisions on the modernization of equipment, meet your needs for the development. Help your company constantly increase your competitiveness in the market and confidently move forward in the field of production of complex fertilizers.

Get solutions for production lines !

We have rich experience in the industry, Professional technical team and integrated service system. We can provide you with a full range of solutions for the production of complex fertilizers. No matter, Are you a newcomer in the industry or an experienced entrepreneur, striving for modernization, We can satisfy your needs. Feel free to contact us, to discuss the decision, which is right for you.

Get solutions for organic fertilizer production lines or equipment prices!