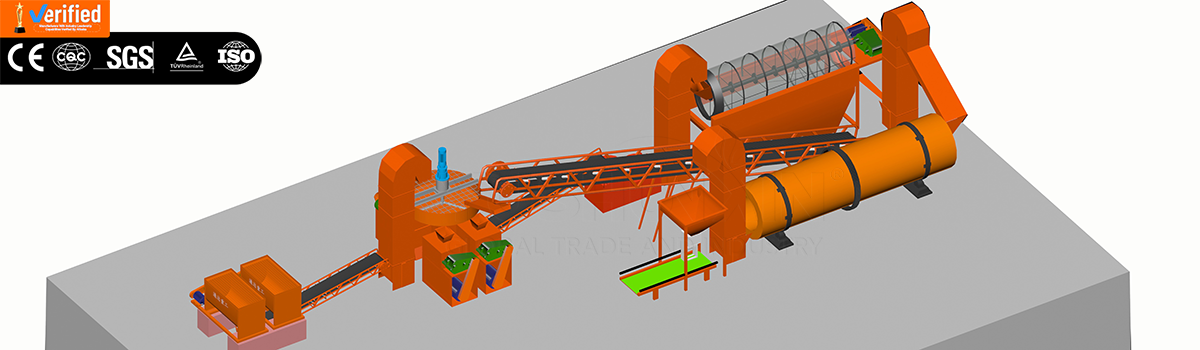

Gumin fertilizer production line, which we provide to you, uses effective production processes and modern equipment. Will help you produce high -quality fertilizers based on humic acid. Our production line includes many links: From the preparation of raw materials, crushing and sorting, processing with acidification before extraction, granulation and packaging. In each link, you use corrosion resistant and high -strength equipment materials for you. Ensure stability and efficiency of production humic acids fertilizers. Based on your acquired equipment for the production of humic fertilizers We will perform production and supply for you in about one month. If you are interested in investing in the line for the production of humic acids or modernizing the existing production line. Welcome, Contact us for consultation and order. If you want to come to our plant to check on the spot, We will be happy to welcome you. Our doors are always open and our objects are waiting for you.

Get an individual solution !

How our Gumin fertilizer production line will help you produce high -quality granular humic fertilizers?

The process of production of humic fertilizers is more complicated, than other fertilizer production processes. Because it involves acidification. Thus, Guminic acid -based fertilizer production line, which we provide to you, includes a number of more advanced technological stages. Will help you produce high -quality fertilizers based on humic acid. First of all, The production line is equipped with modern crushing and sorting equipment. To ensure a homogeneous size of raw materials.

Granulation is an important stage in the production of high -quality granular fertilizers. Our production line uses advanced granulation technology. Combine various granulation methods in accordance with your real situation. Make sure, that the granular humic fertilizer is homogeneous and has the correct size produced. After this, the cooling stage passes through the drying stage. Helps to quickly remove moisture from granules of humic fertilizers, ensuring stability and shelf life of granules. Finally, The size of the obtained particles of humic acid is checked. Pack qualified particles of humic acid.

Get solutions for production lines !

What materials are used in equipment for the production of humic acids, which we provide you?

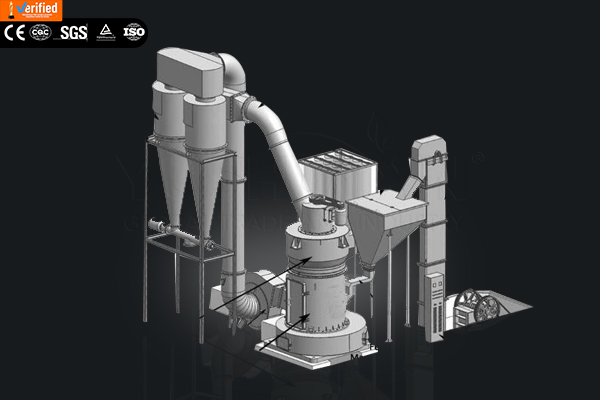

In the process of production of humic fertilizers, sour substances are produced. To make equipment for the production of humic fertilizers more durable. We use various high -strength and stable materials for you. To ensure long -term stable work. Thanks to the use of these high -quality materials. Our equipment for the production of humic acids provides excellent performance and durability in various difficult technological conditions. We strive to provide you with effective and reliable solutions for the production of humic fertilizers. Below are materials, which are usually used in our equipment:

Stainless steel material:

It is mainly used for equipment for processing acidification and neutralization, as well as for details, in direct contact with humic acid. It has excellent corrosion resistance. Enough to maintain a good condition in an acidic environment.

Carbon steel material:

Widely used in crushing-sorting equipment. It provides high strength and wear resistance. Able to withstand large Mechanical loads, equipment arising during operation. Ensure the reliability and efficiency of the production process.

Material made of alloy steel:

Used in granulators and dryers. Has excellent mechanical properties and anti -intelligence properties. Helps maintain stable equipment at high temperatures and high pressure. And significantly extend the life of the equipment.

How much time we need, To complete the production and supply of you acquired line for the production of huminum fertilizers?

Usually from design to production the equipment you ordered for the production of Guminovs Acids pass from 4 to 6 weeks. This period can vary depending on the complexity of the equipment you purchase, special needs for setting up and the size of the project. We will closely communicate with you during production. Make sure, that each aspect corresponds to expectations and meets your specific requirements. Our team will regularly inform you about the progress. And always ready to answer your questions. Ensure the transparency and effectiveness of the entire process.

After that, how the equipment will be manufactured, We will immediately organize a shipment for you. The specific delivery time usually depends on the logistics conditions and the distance between us. This can usually be done within 1-3 weeks. Usually we use FOB to deliver your production equipment. We can help contact the logistics company, If you need it. Providing you with consultations and support on delivery and insurance issues. Ensure safe and efficient delivery of equipment to the assigned place. Please, Feel free to contact us, So that we can better satisfy your needs.

Get solutions for production lines !

What raw materials is suitable for you for the production of humic acid fertilizers?

The production of humic fertilizers is mainly based on natural organic substances, rich in humic acids. Such raw materials, Like weathered coal, peat and brown coal, is an ideal choice for the production of high -quality humic fertilizers. They are not only rich in humic acids, but also effectively extracted by you. Laying the basis for your production of highly effective humic fertilizers.

Peat:

Peat is a substance, formed as a result of prolonged accumulation of plant residues and decomposition of some microorganisms. Rich in organicism and humus. High content of humic acids effectively improves the quality of fertilizers. You can rationally develop and use peat resources. Protect the ecological environment, Producing high -quality fertilizers.

Elongated coal:

Elusted coal - an important resource, spent on the surface of the earth. This is one of the key raw materials for the production of humic fertilizers. It is rich in humic acid and humic substances. Moreover, Eliveted coal underwent a long -term natural processing process, and its internal structure of humic acids is more stable. Easy to extract. Thereby significantly increasing production efficiency.

Lignite.

Lignet is low -quality coal. It has become an important source of extraction of humic acids because of its abundant reserves and a relatively low price. Lignet has good solubility and reactionary ability in the process of extraction. This allows you to effectively increase the efficiency of humic acids and reduce production costs.

What acids can be used in the process of acidification for the production of humic fertilizers?

When extracting and processing humic acid. The acidification process is often used to regulate PH and precipitate humic acid from the solution. Most of humic fertilizer manufacturers usually use the following acids:

- Hydrochloric acid (HCl). Hydrochloric acid - strong acid. It is usually used at the source during extraction of humic acids. It can effectively reduce the pH of the solution and besiege humic acid.

- Sulfuric acid (H2SO4). Sulfuric acid is also widely used by strong acid. Used to decompose and precipitate humic acid. When using sulfuric acid, it is necessary to carefully monitor the concentration, to avoid an excessive reaction.

- Nitric acid (HNI3). Although it is not so widely used, like hydrochloric acid and sulfuric acid, Under certain conditions, nitric acid can also be used to acidify.

- Acetic acid (CH3COOH): Acetic acid is a weak organic acid. Used in situations, when soft operating conditions are required. Its use can reduce environmental impact.

- Phosphoric acid (H3PO4). In some special applications, phosphoric acid can be used to acidify humic acid. However, the scope of its application is relatively limited.

When performing the process of acidification, you need to pay attention to the control of the concentration and the amount of acid. In order to avoid excessive corrosion or pollution of the environment of the system. Besides, handling a spent liquid and residues, formed in the process of acidification, It is also an important aspect to you, which must be taken into account. To ensure operational safety and environmental protection.

What aspects of gumic acid extraction can you optimize?

Improved acidification process:

Accurate control of the concentration of acid and reaction time can help you effectively increase the effectiveness of humic acid extraction. You can control the concentration of acid in real time using a pH meter or other online monitoring device, To guarantee its stability at an optimized level. Heating and cooling systems are used to accurately control the temperature in the reactor.

Optimize your mixing technology:

Select the correct type and size of the mixer. Make sure, that the raw materials are fully in contact with the acid. We recommend, so that the diameter of the mixer usually makes up from 1/3 to 1/2 reactor diameter. And use different speeds and mixing modes at different stages of the reaction. This provides adequate mixing. Accelerate the dissolution of humic acid.

Choose a suitable neutralizer:

Use appropriate neutralizers and methods to maintain stability and activity activity. Such as calcium carbonate, bicarbonate, sodium hydroxide and potassium hydroxide and t. e. These are usually used neutralizing agents for extraction of humic acids. You can choose the most suitable in accordance with your needs. Gradually add a neutralizer, to monitor PH changes and prevent excessive neutralization.

Increase the accuracy of filtering:

The use of high -precision filter equipment can reduce the number of impurities. Improve the purity of the extract. You can also use the multi -stage filtration process to gradual removal of particles of different sizes. To increase filtering accuracy. And introduce an advanced automated monitoring system to adjust production parameters in real time. Ensure the stability and effectiveness of the process of production of humic acids.

Get an individual solution and prices !Shunxin, Your best partner!

If you plan or improve the production of humic fertilizers, We will be happy to provide you with support and consultation. We have rich experience in the industry and a professional technical team. Guminic acid -based fertilizers can be adapted to you. Correspond to the scale of your production and the requirements of the process. Besides, We also have Production linesnicical fertilizers from filled coal, Lines for the production of organic fertilizers from chicken droppings, Lines for the production of organic fertilizers from cow manure and t. e. If you have any questions or you need additional information, Please, Contact us. We strive to become your long -term partner in the production of fertilizers.

Get solutions for production lines !Get solutions for organic fertilizer production lines or equipment prices!