Production of organic fertilizers from silt quickly becomes an effective and environmentally friendly method of waste disposal. This not only reduces the load on the environment, but also provides an economically viable resource. We have a solution for you using IL as a fertilizer. Covers the entire process from pre -processing sediment to packaging ready -made fertilizers.

Besides, To satisfy the specific needs of various customers, We offer Individual solutions for the production line of organic fertilizer of Isil. Feel free to contact us anytime, to discuss in detail your specific requirements with our professional team. Work together on the development of an individual plan, which is best consistent with your practice of agriculture.

Get an individual solution !

As solutions, which we offer you, will help you turn the precipitate into organic fertilizer?

First, the precipitate is pre -processing. Including impurities removal, Separation of solid and liquid phases, concentration, etc.. e. This can be achieved using physical methods (Such as sifting, precipitation) and chemical methods (such as the addition of chemicals for the separation of solid and liquid phases). Then an important stage in the production of organic fertilizers from sediment sets in. The sediment is mixed with other organic materials for fermentation.

Detailed stages of work are as follows: Before adding bacteria, it is necessary to prepare the silt and the corresponding amount of manure or other organic materials (such as straw powder, Arachis shell powder, Rice husk, sawdust, etc.. e in.). Contribute to aeration and adding nutrients for fermentation. If you use rice husk or sawdust, You need to extend the fermentation time, to ensure adequate decomposition. Due to the high content of cellulose and lignin. Then dilute the starter and sprinkle the materials evenly with it, To improve the effect.

In the process of fermentation, organic substances in precipitation are decomposed and transformed by microorganisms. Releases heat and carbon dioxide. Proper temperature control, moisture and ventilation conditions can contribute to the decomposition and transformation of organic substances. Improve the quality of sediment of organic fertilizers.

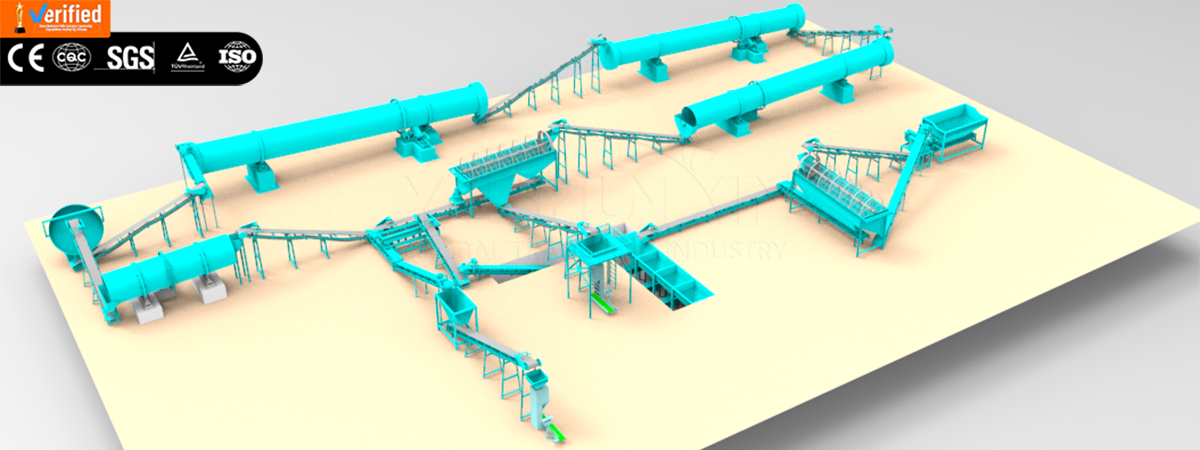

After the fermentation is completed, you can proceed to further processing. Such as drying, Sorting and packaging. Get silt organic fertilizers. This product can be directly used in agriculture and gardening to improve soil structure. Increasing soil fertility and crop yields. With ours line for the production of organic fertilizers from sediment You can successfully use silt as fertilizer. Carry out waste processing and environmental protection.

From which factories you can collect silt for you production of silt organic fertilizers?

Shlah comes from various sources. You can collect silt from various factories and objects below for use in the production of organic fertilizers. Including the paper industry, City treatment facilities, treatment facilities, Food industry enterprises, scottogous and t. e.

- Paper industry. During the production process, the paper industry produces a large amount of sludge. These precipitation are often rich in cellulose and other organic substances. After processing it can be used to produce organic fertilizers.

- Municipal silt. Municipal treatment facilities are the main source of municipal sludge. Sediment, formed when cleaning urban wastewater, It is necessary to stabilize, dehydrate and disinfect. Then it can be used as raw materials for the production of silt fertilizers.

- Wastewater cleaning stations. In addition to city treatment facilities, Some large industrial parks and individual industries also have treatment facilities. Sediment, these enterprises, It can also be disposed of after appropriate processing.

- Food industry. Wastewater cleaning sediment, food industry, usually contains a large amount of organic substances and nutrients. This is a good source of raw materials for organic fertilizers.

- Slaughter industry. During the processing of livestock waste, a large amount of sediment is formed on the cattle -sizes. After proper processing and disinfection, it can be used in the production of silt as a fertilizer. This type of sediment is usually rich in nitrogen, phosphorus and other nutrients.

What kind of raw material is suitable for you for use in the production of silt as a fertilizer?

When choosing sediment, suitable for production as a fertilizer, It is necessary to take into account such factors, as a composition of sediment, Safety and recycling costs. Here are some of the sediment types, which we have chosen for you, which are suitable for fertilizer production:

- Municipal sediment: comes from city treatment facilities. After proper processing, it can be used as raw materials for production. Municipal silt is usually rich in organic substances and nutrients.

- Shlah of the food industry: Shlaam of the food industry is often rich in nutrients. Contains a large amount of organic substances. This makes him a good choice for the manufacture of organic fertilizers.

- Shlaam cellulose and paper: Despite the high fiber content. But after proper processing and deployment. This type of precipitate can improve the structure and moisture adherence to organic fertilizers.

- Precipitation of brewing industry and drinking: This type of precipitation usually contains a large number of sugar and yeast residues. Can provide the soil with a rich organic matter.

- Precipitation from the processing of agricultural manure, cattle and birds: precipitation, formed at livestock objects, poultry farming and agricultural processing. Usually rich in nitrogen, Phosphorus, potassium and other nutrients, necessary for plants.

Before using this silt, It is necessary to carry out comprehensive testing and processing of silt. To remove heavy metals, pathogenic microorganisms and other harmful substances. Ensure its safety and environmental protection. In particular, It is necessary to comply with the relevant national and regional rules and standards for the use of sediment. Ensure the safety of soil and environment.

How to make the composition of silt more stable when using the production of silt as a fertilizer?

Using the composting process, you can effectively turn the precipitate into a stable fertilizer. thereby improving the stability of its ingredients. You can optimize compost conditions for better fermentation. Including temperature control, moisture and ratio of carbon and nitrogen. Besides, Secondary fermentation can also additionally improve stability and maturity of fertilizer sedimentation. At the stage of secondary fermentation, the organic matter in sediment is subject to further decomposition. This helps to improve the physical and chemical properties of fertilizers, making it more suitable for agricultural application.

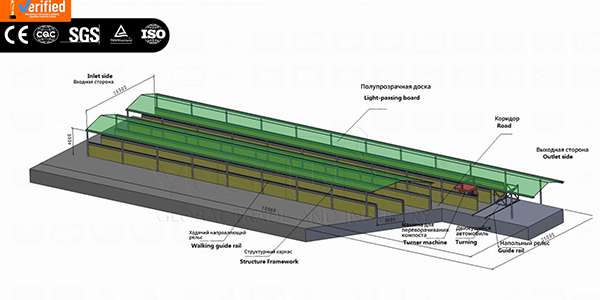

The right choice equipment for composting It can also help stabilize the composition of the sediment. We offer you various options for composting equipment. Can satisfy your needs for the production of compost of various sizes and needs. Such as fermentation reservoirs, Caterpillar composters, Milituted biases of compost, Wheel type of turner for compost and t. e. All these devices can help you optimize the composting process. Improve the quality and stability of sludge fertilizers. Correctly choosing and using this equipment, You can more effectively control the process of composting. High -quality sludge fertilizers.

Get the price for this equipment !

What crushing equipment, suitable for crushing silt, We can provide you with?

When processing sediment. The choice of correct crushing equipment is the key to ensuring the results of its subsequent processing and application. We can provide you with the following types of equipment, suitable for crushing sediment to meet various needs for its processing:

A semi -smoking crusher of materials

This crusher is especially suitable for processing wet sludge. It can effectively process silt materials with a high moisture content. Thanks to the special design of the loading port, Blade designs and unique crushing technology. You can effectively avoid clogging with wet sediment and problems with adhesion. To ensure a smooth and effective process of crushing for you.

New vertical crusher

This crusher is an ideal choice for the processing of ready -made sediment of organic fertilizers, exposed fermentation. It has a simple design, simplicity of service and high efficiency of crushing. A new vertical crusher can additionally grind the finished enzyme sediment of organic fertilizers to suitable size. To facilitate subsequent processing, packaging and application.

Correctly choosing crushing equipment, You can not only increase the efficiency of production and processing of silt as a fertilizer, but also improve the quality of the final product. Makes it more suitable for use as agricultural fertilizer or other purposes. Our equipment is developed taking into account the special needs for the processing of sediment. Ensure an effective and reliable effect of crushing. Welcome, Contact us to buy.

What are the advantages of silt organic fertilizers cost your investment in production?

Silt organic fertilizers have significant economic advantages in economic terms. Transforming silt into valuable products, You can reduce wastewater treatment costs. If you have a treatment plant and related enterprises, You can increase your additional economic benefit. Silt organic fertilizer as organic fertilizer, market demand for it is growing. Moreover, The price of sediment as fertilizers in the market can be higher, than the price of chemical fertilizer. It has great profit potential and deserves your investment consideration. Welcome, Contact us, to order a line for the production of organic fertilizers from sediment. Let us help you produce high -quality silt fertilizers.

In addition solutions for the production of organic fertilizers from sediment, We can also provide you Other fertilizer solutions. For example, organic fertilizer from chicken droppings, organic fertilizer from cow manure, Organic fertilizer made of eliminated coal and t. e. These products effectively use by -products of agriculture and industry and correspond to sustainable development trends. Our team has a rich industry experience and professional skills. The ability to adapt production solutions to your specific needs. Provide the most efficient use of resources and maximum economic benefits. Would you like to improve the existing production system or plan to build a new fertilizer production plant. We can provide you with comprehensive support. Welcome to cooperate with us.

Get solutions for organic fertilizer production lines or equipment prices!