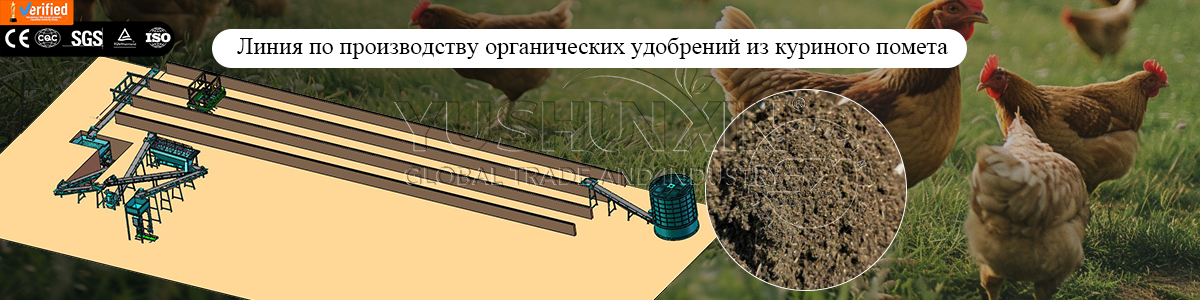

Production line organic fertilizer based on chicken droppings is a line for the production of organic fertilizers, intended for processing chicken litter in fertilizer. In this process, chicken ladder passes a number of strictly controlled stages, such as fermentation, Grinding, mixing, Granulation and drying. Turn into an organic fertilizer, rich in nitrogen, Phosphorus, potassium and various trace elements. Our line for the production of organic fertilizers from chicken droppings can not only effectively reduce environmental pollution, caused by chicken. It can also increase its value as fertilizers.

If you want Open the Kurin litter processing plant for organic fertilizers? If you are still worried about that, how to use chicken sections as efficiently as possible? Welcome, Contact us, to get a decision, which suits you.

Two different forms of production lines organic fertilizer based on chicken droppings to satisfy your different needs.

The line for the production of organic fertilizers from chicken droppings can be divided into two types: powder and granular depending on the shape of the final product. The production processes of these two production lines are different. But they are all intended for that, To help you turn chicken droppings into more environmentally friendly and economical organic fertilizers. Fine fertilizers are suitable for direct application or as a basic fertilizer. Granular fertilizers are more suitable for mechanized introduction. You can choose a suitable technological route, Based on market demand and production conditions.

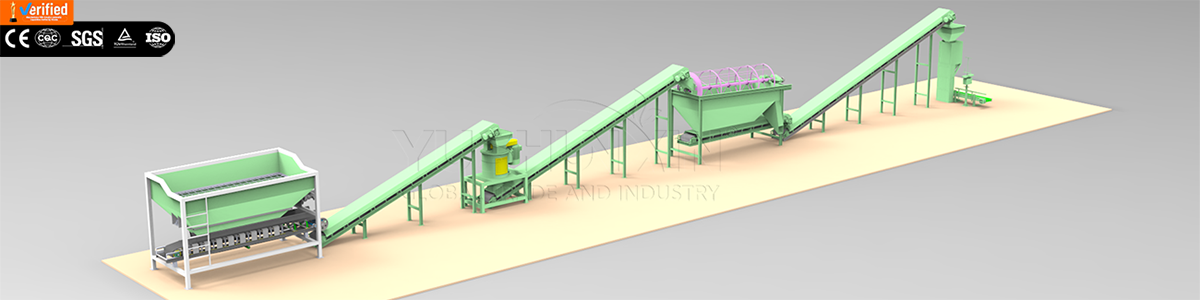

Line for the production of organic fertilizers in the form of powder chicken droppings

The production line begins with the collection of raw materials. You will need to collect fresh chicken droppings and, if necessary, mix it with other organic substances. For example, straw or siderates, to adjust the ratio of carbon and nitrogen. This is crucial for the subsequent process of high -temperature fermentation. Further, the chicken mark is dehydrated through A solid -fingered separator. Bring it to the level of humidity, suitable for fermentation. Then go to the stage of high -temperature fermentation. A bunch of fermentation regularly turned over with the help composter, to provide sufficient oxygen supply and uniform temperature. This fermentation process usually lasts 1-2 weeks. He can effectively kill bacteria and insect eggs in compost.

After the completion of fermentation, the material will become loose, And at this time, chicken droppings will become an organic fertilizer made of chicken droppings. However, to ensure the quality of the finished product, additional processing procedures are needed. The first step is to send the materials to the crusher for cleaning. Unsalified particles are then removed using sorting equipment, to guarantee the subtlety and uniformity of the product. Finally, The finished product is packaged through an automatic packaging machine. And indicate information about the product of organic fertilizer from chicken droppings. It is also hermetically closed to prevent moisture and track.

Click, To find out more: The line for the production of organic fertilizers from chicken droppings 20 000 $.

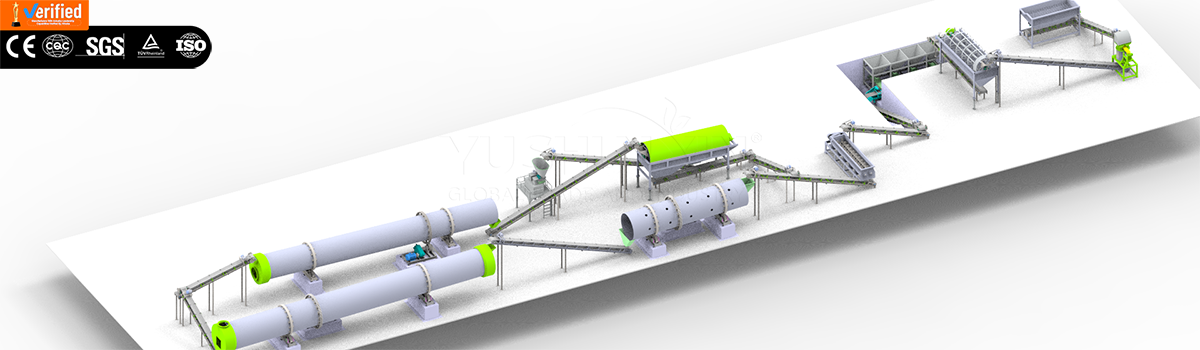

Line for the production of organic fertilizers from granular chicken droppings.

Unlike the process of production of powdered organic fertilizers, Granular organic fertilizers from chicken droppings require the mixing process after grinding compost. To increase the content of nutrients in the product. Mixed materials enter the granulation process and Formed in granules through granulator. The size and density of particles can be adjusted in accordance with the specific needs. After granulation is completed, the finished granules still contain a certain amount of moisture. To improve stability during storage, further drying is necessary. Then the dried granules cool, to prevent agglomeration and destruction.

Finally, Chilled granules are dried and sifted. Removal of unsifty particles and dust to ensure homogeneity and product quality. Qualified granular fertilizers are weighed and packaged using automatic packaging machines. And march it for storage and subsequent transportation.

What is the price of our line for the production of organic fertilizers from chicken droppings? The annual production volume is 10 000 Tons / 50 000 tons / 100 000 ton.

For the price of a line for the production of organic fertilizers from chicken droppings, which we sell, Many factors affect. Including the scale of the production line, Equipment configuration, The degree of automation, Transportation and installation costs and t. e. The most important influencing factors are the scale of the production line and the configuration of equipment. Below we will introduce you prices for the line for the production of granules and powder lines of three levels: annual performance 10 000 Tons / 50 000 tons / 100 000 ton. For your information.

The line for the production of organic fertilizers from chicken droppings with performance 10 000 tons per year.

- Powder line: around 13,606,64 US dollars(1,361,000 rub).

- Granulatory production line: About $ 27,218.27(2,723,000 rub).

Performance 50 000 tons per year for production organic fertilizer based on chicken droppings.

- Powder line: usually about 19.991 US dollars(2,000,000 rub).

- Granulatory production line: About $ 49,997(5,000,000 rub).

100 000 tons per year line for the production of organic fertilizers from chicken droppings with performance.

- Powder line: about 40.847.61 US dollars(4,085,000 rub).

- Granulation line: Usually about $ 67,972.33(6,800,000 rub).

If you have a limited budget and you want to start the production of organic fertilizers from chicken droppings, Having bought the main equipment for starters, what equipment do you need?

If your budget is limited, You should first purchase the main equipment for fermentation and granulation.

Equipment for fermentation: Self -propelled tile of manure (width 2–3 m, The price is about 1000-1500 US dollars). It does not require caterpillars and is distinguished by the flexibility of control. Can effectively overwhelm chicken droppings and promote fermentation. If the conditions on the spot allow, you can also use a simple fermentation trough (which can be built independently and save).

Equipment for granulation: A granulator with a stirrer (Productivity 1-8 tons/h, The price is about 1000-3000 US dollars). It has a simple design, Convenient in operation and adapts well to chicken droppings. Mixed material can be easily processed into granules.

Auxiliary equipment: A crusher of a half -fingered material (Productivity 1-8 tons/h, Cost of about 300-1000 US dollars). Used to grind the fermented chicken litter for granular. Horizontal mixer (performance 2-5 tons/time, price around 100-500 US dollars). Mix chicken droppings with auxiliary materials and microbial agents. With sufficient financing, dryers will be added, sifting cars, packaging machines and other equipment for the completion of the production line.

Contact us, To find out the price !

What materials do we use in the production of equipment for the production of organic fertilizers from chicken droppings for you?

As a professional manufacturer of equipment for organic fertilizers with rich production experience. We know, that in the production of equipment for the production of organic fertilizers from chicken droppings, it is extremely important to choose the right materials. Because the equipment must withstand certain mechanical loads, chemical corrosion and wear as a result of frequent operations. Below are our frequently used materials and their advantages:

Three common materials for our production equipment and their advantages:

1. Steel Q235: This is ordinary carbon structural steel. Has good plasticity and welding properties. Therefore, we widely use it for the manufacture of frames and structural elements of various mechanical equipment.

2. Alloy steel. For components, requiring higher strength and wear resistance, We use alloy steel. Alloy steel has a higher strength, firmness and corrosion resistance. This material is usually used to make bearings, gears and other important moving parts of the equipment.

3. Stainless steel. Stainless steel - the perfect choice of material there, where it is necessary to prevent corrosion (For example, Details, in direct contact with chicken droppings). Our most frequently used stainless steel models include brands 304 And 316. They provide good corrosion resistance and durability.

Contact us, To find out the price !What factors affect the quality of fertilizer in the process of processing chicken droppings into fertilizers?

Influence factor 1: The quality of the compost

The production process of organic fertilizer based on chicken droppings is actually the process of composting. The quality of the compost affects the quality of organic fertilizers. Therefore, accurate control over the parameters of the composting process is necessary. First, What you need to pay attention to is moisture. Ideal humidity should be maintained at 50-60%. Because too high humidity can cause anaerobic fermentation and the appearance of smell. Too low humidity does not contribute to microbial activity.

Influence factor 2: Carbon ratio and nitrogen

Secondly, This is the ratio of carbon and nitrogen. The ratio of carbon and nitrogen should be in the range of 25:1 to 30:1. Since chicken droppings have a high nitrogen content, It can be adjusted, Adding materials with a high carbon content, such as straw and rice husk. During PH, PH should also be maintained at 6.5–8.5. Too sour or too alkaline environment will affect the activity of microorganisms. In addition to this, you also need to make sure, that during the composting process there is a sufficient supply of oxygen. To stimulate aerobic microbial activity and prevent anaerobic fermentation.

More factors, affecting the quality of compost:Six factors, affecting the quality of compost.

What excipients can you add to the process of chicken droppings?

In the process of fermentation of chicken, you can add various auxiliary materials to optimize the fermentation process. By rational choice and comparison of these excipients. Thereby improving the quality of the final product organic fertilizer based on chicken droppings. The following are some common auxiliary substances:

- Straw, sawdust, rice husk or peanuts: These materials can help adjust the ratio of carbon and nitrogen in chicken litter. The chicken drop is rich in nitrogen. These materials are rich in carbon. Mixing them, you can achieve the perfect ratio of carbon and nitrogen (Usually from 25:1 to 30:1).

- Gypsum or phosphorite powder: Used to regulate the PH of Enzymatic Materials. Chicken droppings usually sour, and the addition of gypsum or phosphorite flour can neutralize the acidity.

- Biochol: Biode can improve the structure of your compost, increasing the aeration and water holding ability. It also helps to consolidate nutrients in compost and reduce ammonia..

- Microbial agents: These agents can accelerate the decomposition of organic substances and increase the efficiency and effect of fermentation. These include lactobacilli, yeast, Actinomycetes and others. Has a certain inhibitory effect on pathogenic bacteria.

Which granulator can be used to produce organic fertilizer granules from chicken droppings?

Granular organic fertilizers are very popular in the market. Most manufacturers of organic fertilizers choose a disk or roller granulator for the production of organic fertilizer from chicken droppings.

- Disc granulator has a simple design and is convenient to maintain. More suitable for production on various scale, especially for materials with high humidity. The size of the particles of organic fertilizer from chicken droppings is regulated and has a high degree of adaptability. The performance of our disk granulator is 0,02-6 t/h.

- Double roller extrusion granulator Suitable for large -scale production. It has high efficiency and low energy consumption and can produce particles of organic fertilizers of high density. However, there are higher requirements for moisture and size of the material. The performance of our two -wound granulator is 0,8-4 t/h.

When choosing a granulator, the scale of production should be taken into account, Material characteristics and market demand for granules quality. You can contact us, To learn about the suitable equipment for you to gran chicken droppings.

The manufacturer of equipment for the production of organic fertilizers from chicken droppings is recommended – Shunxin!

Shunxin - Enterprise, specializing in research, development, production and sale of equipment for organic fertilizers. Especially in the field of production, organic fertilizer based on chicken droppings, it has rich experience and technical advantages. Shunxin can provide you with various characteristics and models of equipment for the production of organic fertilizers from chicken droppings. Capable of satisfying your various sizes and needs. Thanks to high -quality products and services, Shunxin enjoys a good reputation in the industry and among customers. Many customers leave positive reviews and recommendations.

Get solutions for production lines !

Shunxin,Your best partner!

In addition to the solutions for production, organic fertilizer based on chicken droppings we can also provide you with various Solutions for the production of organic fertilizers. Help you achieve waste resources. Feel free to send us an email, By pressing the button or using the form below. We will contact you, As soon as we see. If you have time, We invite you to visit our factory.

Get solutions for organic fertilizer production lines or equipment prices!