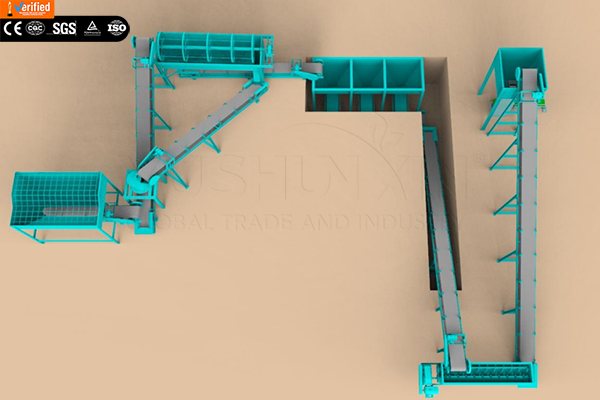

Ours decision: Horse manure like fertilizer aimed at transforming agricultural waste into effective organic fertilizers. Provide sustainable development solutions for modern agriculture. The main goal of this line is to use nutrients, which is rich in horse manure. Thanks to scientific technological processes, the disposal of nutrients is achieved. Provides high -quality soil fertilizers for agricultural crops. Production process of the production line, which we provide you, Includes the collection of raw materials, enzymatic processing, drying, crushing, Sorting and final packaging. Make sure, that you get the best results at each stage in the way. We provide individual solutions for production lines. Covers the full range of services from initial design to installation and commissioning. Welcome, Contact us and work together.

Get an individual solution !

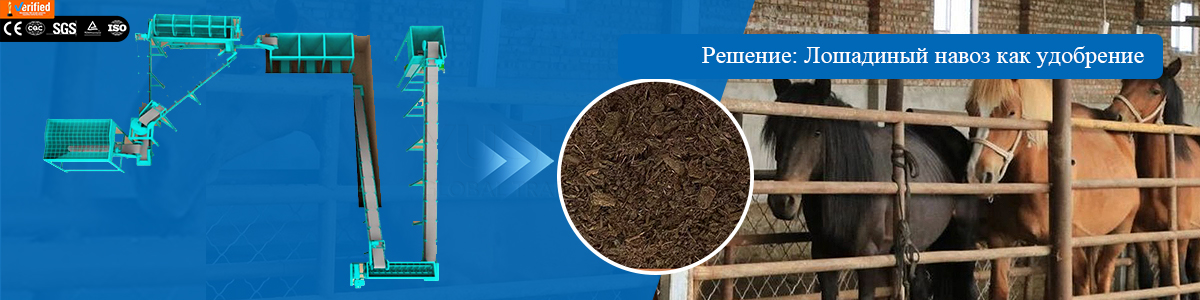

Why horse manure is suitable for you to use fertilizer production?

Horse manure is suitable for use in production horse manure as fertilizer, since it is rich in organic substances and the necessary nutrients, necessary for the growth of many plant species. For example, nitrogen, phosphorus, potassium, etc.. e. These elements are necessary for healthy plant growth. Can improve soil structure and increase fertility. Besides, An important role is played by the microbial activity of horse manure. These microorganisms accelerate the process of decomposition of organic substances. Convert complex organic compounds to low molecular weight nutrients, which are more easily absorbed by plants. This process not only provides a steady and gentle fertilizer effect, but also effectively reduces the risk of a “burn of roots” of plants. Make sure, that plants are capable of safely and cool to absorb nutrients. We strive to provide our customers with individual production solutions to satisfy various specific needs. If you are interested, Please, Feel free to contact us.

As our horse manure as fertilizer, the solution can help you produce environmentally friendly organic fertilizer from horse manure?

The production of environmentally friendly organic fertilizers from horse manure requires careful handling and careful operation on your part. To guarantee, that the product has the effective effectiveness of fertilizers and environmentally friendly characteristics. For this reason, we specially prepared for you a line for the production of organic fertilizers from horse manure. We cover the entire process from processing raw materials to packing ready -made fertilizers. Using this process, you can produce high -quality, Environmentally friendly organic fertilizer from horse manure. Welcome, Contact us, To configure and purchase a suitable line for the production of organic fertilizers from horse manure.

The main production process is horse manure as a fertilizer:

- Collect and prepare raw materials: Fold the collected fresh horse manure together. Other organic materials can be added at the same time, such as straw or wood chips. To adjust the ratio of carbon and nitrogen. These materials help improve aeration and water absorption of compost.

- Adjust the humidity: The optimal humidity of the compost is usually 50-60%. If it is too wet, Add dry organic material. If it is too dry, Add water accordingly.

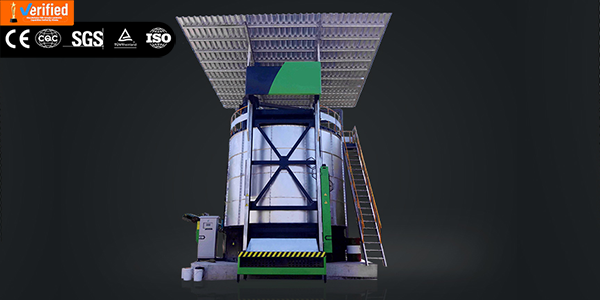

- Preparation of compost: Fold mixed materials in a heap. Make sure, that the stack has a suitable height and width. To facilitate air circulation. We have a composter for you. Use a compost enumet, To turn the bunch, to increase oxygen supply. Stimulate microbial activity.

- Temperature monitoring: During the composting process, the temperature will increase. Regularly control the temperature, so that it remains at the level of 55–65 degrees Celsius for several days. To destroy pathogens and weeds.

- Cooling and ripening: Compost matures, when the compost temperature drops to the ambient temperature and remains stable. At this stage, the material should be dark brown, soft in texture and not have a clear smell.

- Crushing and mixing: Mature compost is additionally crushed. Thereby improving compost uniformity and covering the effect when making. Then, with the help of a blender, minerals are added, rich in specific nutrients, To enhance the fertilizer effect.

- Sifting and packaging: Use sorting equipment to remove large pieces of material. The sifted compost, if desired, can be additionally processed into granules or powder. Then pack and store.

What is the key to production horse manure as fertilizer? Will help you produce better organic fertilizers from horse manure.

The key to the production of horse manure as a fertilizer is Correct handling of compost. Ensure the quality and effectiveness of the final product. Among them, the ratio of carbon and nitrogen and moisture content during composting are two important parameters. They directly affect the effectiveness of the composting process and the quality of the final product. The correct ratio of carbon and nitrogen ensures the optimal activity of microorganisms. This contributes to the rapid decomposition of organic substances. The corresponding moisture content can ensure the habitat, required microorganisms. Avoid anaerobic conditions.

In the process of composting, adjusting the ratio of carbon and nitrogen and moisture content usually requires the addition of various materials. For example, If your compost is high nitrogen content, You can add materials with a high carbon content. Straw or wood chips to increase the ratio of carbon and nitrogen. Moisture content can be adjusted by spraying water or adding dry materials. Besides, Regular turning evenly distributes nutrients and moisture, improves aeration of the compost heap. Favors the activities of aerobic microorganisms.

If you have questions about that, how to make adjustments or what materials need to add, Please, Contact us.

Get solutions for production lines !

Which line for the production of organic fertilizers from horse manure is suitable for you to invest?

When considering the issue of, In which one line for the production of organic fertilizers from horse manure invest. You need to take into account your financial budget, The size of your horse farm and the simplicity of collecting ingredients. If you have an equestrian farm and you have a constant stock of horse manure. A small line for the production of powdered organic fertilizers is really a good choice. It will help you effectively process and use horse manure and turn it into a valuable organic fertilizer. Thereby supporting your agricultural or garden projects.

If you do not have a permanent source of horse manure, But you would like to invest in the production of organic fertilizers. We recommend that you consider the possibility of using other organic fertilizers based on an early. For example, organic fertilizer from chicken droppings, organic fertilizer from cow manure and t. e. Use all the farms next to you and get a stable source of raw materials. We also have solutions for the production of organic fertilizers based on early. In accordance with your production raw materials, we can set up a suitable production line for you. Welcome, Contact us to solve.

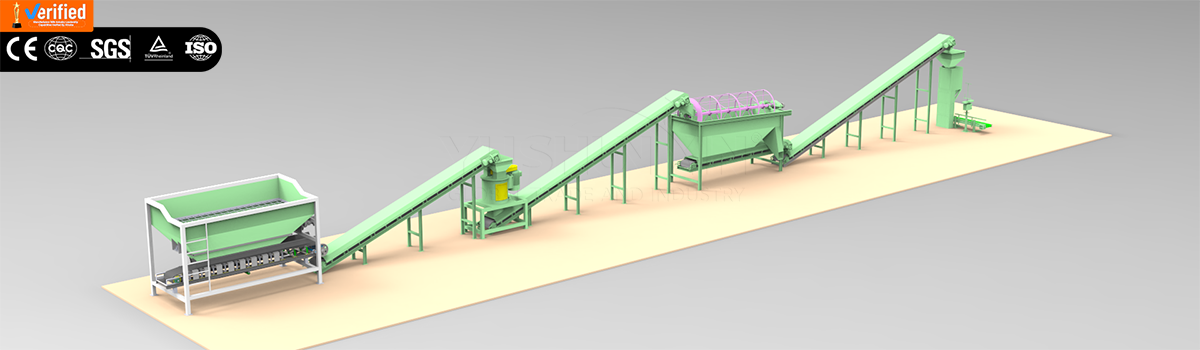

Production equipment design plan: line for the production of powdered organic fertilizers with performance 3000 tons of horse manure per year.

For designing a line for the production of powdered organic fertilizers from horse manure with performance 3000 tons per year must be selected and configured for the right production equipment. Provide efficient production. The following is the equipment selection plan for us., suitable for the production of powdered organic fertilizers. An annual production volume can reach 3000 ton. This production line is suitable for investment of horse farms.

List of basic equipment 3000 tons/year of the line for the production of organic fertilizers from horse manure

- A crusher of a half -fingered material: used to grind horse manure and other auxiliary materials (such as straw, rice husk and t. e in.) On small particles. Effectively copes with various wet and fibrous materials.

- Caterpillar coup mechanism: Suitable for aerobic fermentation of stacking type. Fold the raw materials in stacks and regularly turn the stacks. Provides uniform fermentation and accelerates the fermentation process. You can choose a suitable model of a caterpillar composter, corresponding to your production needs.

- Capacity for fermentation of organic fertilizers (option): Used for closed fermentation. Suitable for cases with limited space or high environmental requirements.

- New vertical crusher: Grind the shot materials again. Provides fine powder, increasing the uniformity and effectiveness of fertilizers. This is an effective grinding equipment for organic fertilizers.

- Powder to the sorter: used to remove large particles and impurities from mature compost. Ensure the details of the product details to market demand.

- Twarge horizontal mixer: Mix crushed mature compost evenly with other additional ingredients (For example, microelements). Improve the nutritional value and effectiveness of fertilizers.

- Semi -automatic packaging machine: used for quantitative packaging of ready -made powder organic fertilizers. A semi -automatic design can not only satisfy your packaging needs, but also reduce investment costs for equipment.

If you need to configure the line for the production of organic fertilizers from horse manure, What information do you need to provide us?

If you are looking for our individual solution for using horse manure as fertilizer. Buy a full line for the production of organic fertilizers from horse manure. Well, by e -mail or subsequent communication. You need to provide us with more detailed information. For example, Your annual production needs, Requirements for the form and composition of products, Square and layout of the plant, budget range and t. e. Besides, If you have other special requirements, Please, Tell us. Such as environmental protection standards and the degree of automation. This information will help us develop the best configuration of the production line for you. Detailed communication at the beginning of the project can help you fully satisfy all your needs.

In addition to providing you with a solution for using horse manure as a fertilizer, We also offer many other solutions for the production of fertilizers. Be it organic fertilizer from chicken droppings, organic fertilizer from cow manure and other production of organic fertilizers from manure. Or production Elustible coal, humic acids and other humic organic fertilizers. We all have appropriate professional solutions. Feel free to contact us to receive additional information and individual offers.

Get solutions for organic fertilizer production lines or equipment prices!