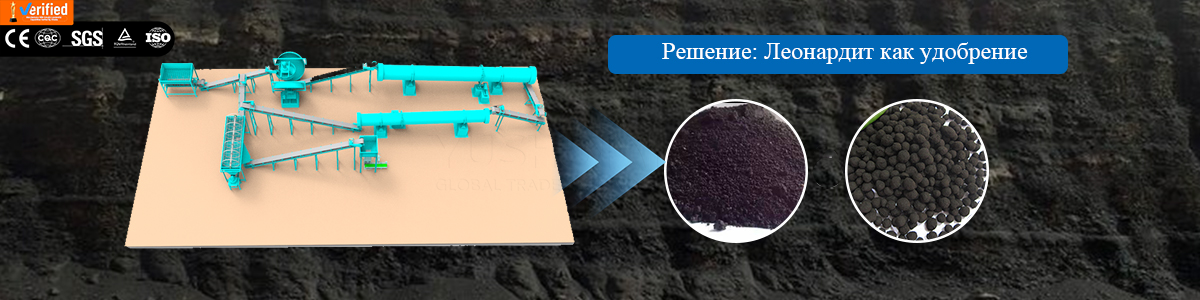

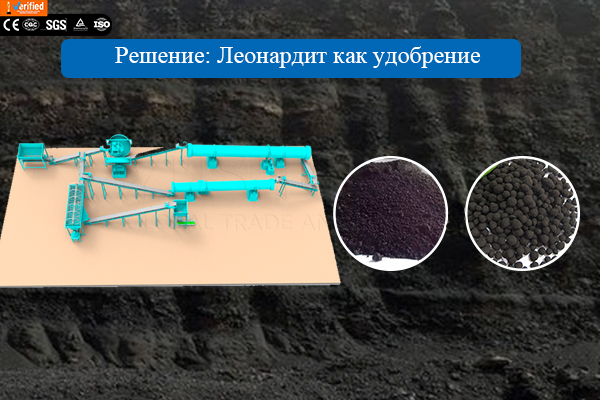

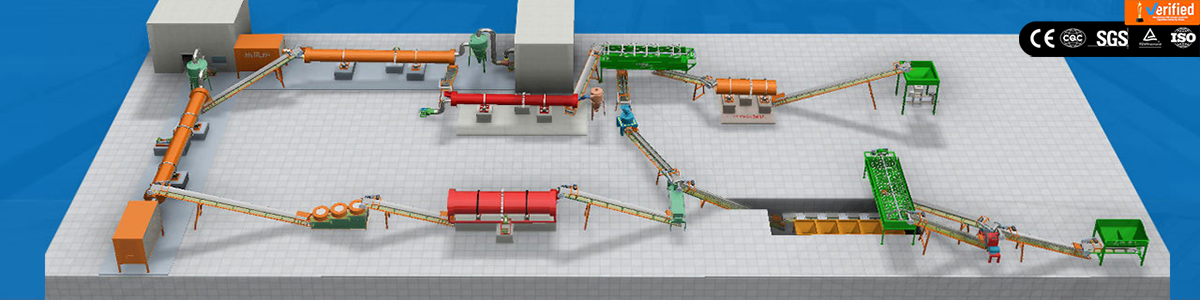

Elusted coal is usually considered imperfect fuel due to its unstable nature. However, with proper processing, weathered coal can turn into a valuable Leonardite fertilizer. Thereby significantly improving its economic value. We provide you with an effective line for the production of organic fertilizers from the weathering coal. Comprehensive assistance in converting filled coal into high -quality organic fertilizer. Our solutions for production lines cover the entire process: from preliminary processing of raw materials, crushing, mixing and fermentation until final granulation and packaging of finished products. Each stage is carefully developed and optimized. To ensure high efficiency of production of outlet carbular fertilizers and high quality of finished products from dedicated coal fertilizers.

How Professional manufacturer of equipment for the production of coal fertilizers. We not only provide you with effective and reliable equipment of production lines, But we also provide comprehensive technical support and consulting services. We will develop for you the most suitable production plan, taking into account your specific needs and production conditions. Help you successfully transform and develop an outdated carbon fertilizer market. Welcome, Contact us, To order. If you have time, Welcome to our factory and talk with engineers face to face. Create a suitable line for the production of Leonardite Fertilizer.

Get an individual solution !

Why is it better used in the production of fertilizers, than fuel?

Elusting of coal is the result of a long effect of the environment. There are various degrees of decomposition and oxidation. As a result, its heat -intensive ability below, And its competitiveness as fuel in the market is weaker. However, the outlet coal is rich in humic acid. This is a great air conditioning for soil and plant growth stimulator. Humic acid can improve the structure of the soil and increase the retention of soil moisture and fertilizers. At the same time, it contributes to the development of the root system of plants. These properties make the weeded coal more valuable for agriculture. The transformation of thewashing coal into organic fertilizers on our production line can bring you a lot of profit.

Get solutions for production lines !

The production process of the line for the production of organic fertilizers from the inlet of coal We provide you:

- Preparation of raw materials: You need to transport the weathered coal from the production zone to the production workshop. Perform preliminary screening and removal of impurities.

- Crushing: In this production process, the weathered coal must be grinded to a certain size. Promote the smooth passage of the subsequent granulation process.

- Mixing: Mix crushed elbow coal with other organic materials (For example, manure, vegetable residues and t. e in.) In proportions. To increase the efficiency of fertilizers. Provides the final quality of Leonardite products Fertilizer.

- Fermentation: Mixed materials are subjected to Aerobic fermentation in the enzyme reservoir. Increase the content of humic acids and the effectiveness of the transformation of organic substances in fertilizers due to microbial exposure.

- Wet granulation: The process of wet granulation is used for transformations of enzyme materials into granules. This method works in conditions of high humidity. This can effectively improve the uniformity and strength of particles.

- Drying and cooling: After that, How particles are formed, They must be dried, to remove excess moisture. And maintain the stability of the product by cooling.

- Sorting and packaging: sorting ready -made coal particles. Delete unskilled particles. And qualified particles are packaged and stored.

What are the features of the Leonardite line of the fertilizer, which we provide to you?

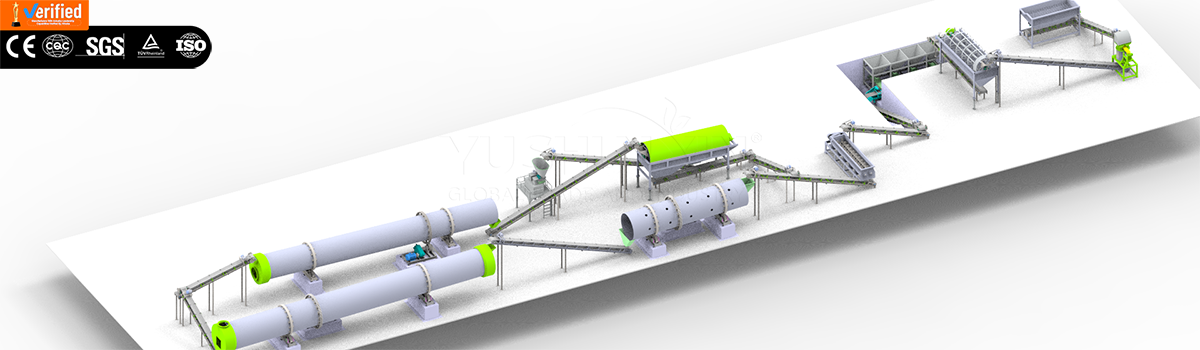

The line we provide for the production of organic fertilizers from the inlet coal is equipped with an intellectual control system. Allows you to control and adjust the parameters of each link in real time. Provide the stability and consistency of the product in the production of Leonardit organic fertilizer. This allows you to achieve effective and high -quality production.

At the stage of crushing, we use modern and effective crushing equipment for you. It can grind the weathered coal to the optimal particle size and provide good conditions for subsequent processing. simultaneously increasing the overall efficiency of production. Besides, In containers for Leonardite, which we provide, The technology of accurate fermentation is used. Equipped with modern ventilation and mixing systems. Ensure the microbial activity and uniformity of the fermentation process.

In the process of granulation, we use for you the technology of wet granulation. Ensure the strength of thewashed particles of coal fertilizer and the activity of organic substances. Besides, The production line is designed with full accounting of energy consumption and environmental protection. Due to the system of recovery of energy and the exhaust gas purification system. Significantly reduce carbon dioxide emissions and environmental pollution during the production of eliminated carbon fertilizers. Help you get economic benefit, and also contribute to the environmental protection.

Why do we prefer to use the process of wet granulation, To help you produce Leonardite Fertilizer?

The process of wet granulation is the most common and popular granulation process. It has significant advantages. In the process of granulation, it not only provides the strength of the weathering particles of coal fertilizer, but also maximizes the activity of organic substances. In this method, a liquid mixture is used to glue materials (water, glue, etc.. e in.). This allows you to get homogeneous and dense particles. Compared to traditional granulation methods, the physical properties and the efficiency of using the nutrients of granules can be improved. Besides, The process of wet granulation is usually carried out at lower temperatures, which reduces damage to heat -sensitive materials. Active ingredients of organic matter of thewashing coal are better preserved. Improve the quality of Leonardite Fertilizer, which you produce.

Widespread wet granulators include: disc granulator, Drum granulator, New granulator with a toothed mixer for organic fertilizers.

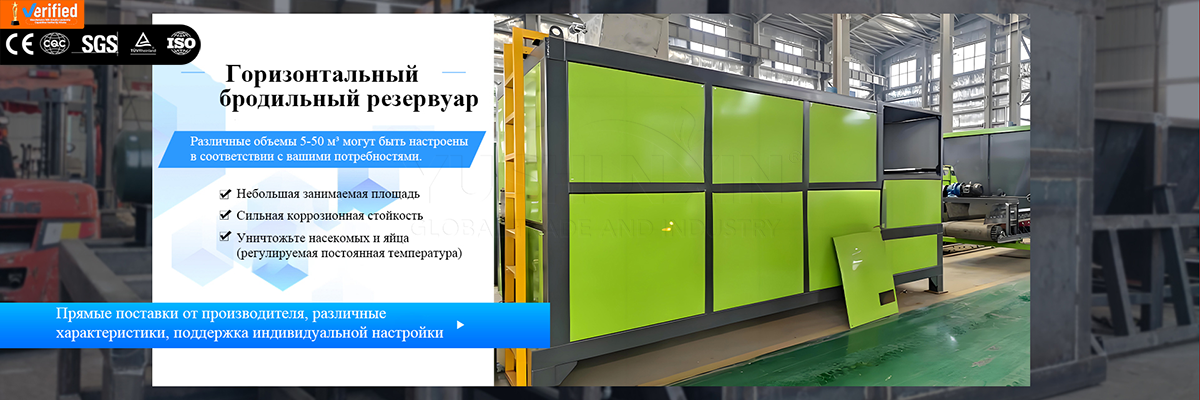

How long the weathering coal compost mixture should roam in the enzyme?

Slotted coal contains a certain amount of humus, and the content of humic acid can be increased due to fermentation. and turns organic substances into an indulged coal into nutrients, which are more easily absorbed by plants. Tank for fermentation of coal compost, which we provide you, can be made for 7-14 days. He uses aerobic fermentation technology. Thanks to the active action of organic microorganisms, in the-injected coal-compass mixture gradually decomposes. Thereby increasing the content of humic acid. Our decisions not only increase the effectiveness of enzyme, but also provide high quality of the final -invented coal fertilizer.

We offer as horizontal, so vertical enzymes. To satisfy your diverse needs for the fermentation of the weathered coal mixture. Depending on your specific requirements, we can make for you Armor reservoirs with capacity from 30 m³ to 150 m³. Each model of the fermentation tank is equipped with effective devices for mixing and ventilation. Provide sufficient oxygen supply to maintain the ideal conditions of aerobic fermentation. Regardless of the size of your project, We can offer you an individual solution. Help your process of carbon fertilizer production to achieve optimal performance.

Get an individual solution and prices !What raw materials can be added in the production of organic fertilizer from filmed coal to improve the quality of the finished fertilizer?

In the process of production of organic fertilizer from the outstretched coal, the choice of correct raw materials is crucial for improving the quality and functionality of the finished fertilizer. Elusted coal itself contains a certain amount of organic matter. But to achieve the effect of replenishing nutrients and improving the soil, necessary for the growth of agricultural crops, You can increase the overall effectiveness of fertilizers due to the synergistic effect of several types of raw materials.

The main raw materials for the production of lifting coal of organic fertilizer:

- Preferred use of dedicated coal: Elusted coal is the main ingredient of organic fertilizers, And we recommend, so that its share is 30-60 % from the total mass of the mixture. This choice contributes to the enrichment of the soil with organic substances and trace elements, Increasing fertilizer efficiency.

- Activated organic matter: The nutritional value of organic fertilizer based on the weathering of coal can be effectively increased by introducing activated manure and bird manure. Acting processing can effectively improve the availability and stability of organic matter.

- Optimized adding NPK: Depending on the needs of the soil and agricultural crops, mineral fertilizers are accurately added, Such as nitrogen, phosphorus and potassium (NPK). Provide the food fullness of the finished fertilizer.

Auxiliary materials, which can be added if desired in the production of organic fertilizer from weathering coal:

- Microbial agents: Add useful microbial agents, Such as bacteria, fixing nitrogen, bacteria, dissolving phosphate, and bacteria, dissolving potassium. It can contribute to the processing of nutrients in the soil and increase the efficiency of fertilizers.

- Humic acid: Adding humic acid, you can improve the ability to retain nutrients and hold water in the soil. At the same time, it contributes to the absorption of nutrients by plants.

- Extract of seaweed: Extract is rich in plants and growth hormones of plants. Helps to increase the resistance and growth rate of plants.

- Lignin and cellulose: by increasing the content of fiber in organic fertilizers. Improve the aeration of the soil and its water holding ability.

- Supporting trace elements: Add trace elements, Such as zinc, Iron, Copper and manganese, In accordance with the specific needs of agricultural crops and soil. To meet the needs of plant growth.

To what size of particles do you need to grind the weathered coal, to get better Leonardite Fertilizer?

For that, so that you can produce better Leonardite fertilizers. We recommend grind the weathered coal before mixing it with other materials. However, a different size of crushing particles in different ways affects the effectiveness of fertilizers. According to the data, The optimal particle size is 50 oven. He can not only provide sufficient surface area and microbial activity, but also to avoid the problem of agglomeration of too small particles. This is the best choice for the production of high -quality coal fertilizers.

Elusted coal is crushed, The size of the particles exceeds 50 oven.

Crushing of carbon coal with particles is too large (less 50 oven) can lead to insufficient area surface area. This limits the effect microbes and the effectiveness of fermentation during composting. As a result, there is a slow release of nutrients of fertilizers. Influence it, To quickly and effectively provide plants with the necessary nutrients. Besides, too large particles difficult to evenly distribute in the soil evenly. Can cause uneven fertilizer application, influencing plant growth and health.

The size of the crushing particles of the filled coal is equal 50 oven.

Crushing 50 Mesh is the best choice for the production of high -quality Leonardite Fertilizer. This small particle size helps to increase the surface area of the material. Thereby improving the effectiveness of the contact of microorganisms and the speed of fermentation. At the same time, particle size 50 The bag also contributes to the uniform distribution of oxygen and moisture in the process of composting. Further optimization of aerobic fermentation conditions. It also avoids the problem of agglomeration of too small particles.

The filtered coal is crushed, The size of the particles is less 50 oven.

Although the crushing of the weathering coal with a too small particle size (more 50 oven) can increase the surface area. But this can lead to another problem: too small particles can lead to their sticking under pressure. Especially in a humid environment. This affects the aeration of fertilizers and moisture penetration. At the same time, too small particles can cause damage when inflating by the wind. Reduce the effectiveness and use of fertilizers.

If you are worried about that, how to use the weathered coal as efficiently as possible? Our line for the production of Leonardit Fertilizer may be exactly the decision, which you need. We provide integrated individual services, to ensure the most efficient use of your weeded coal resources. If you are interested in our line for the production of organic fertilizers from the weathering coal, Please, Contact our professional consulting team.

You can also visit our factory for personal communication and development of solutions with experienced engineers. Thanks to inspections on the spot, you can get a more intuitive idea of our production equipment and technical processes. In addition to the weathering coal, We also have Schlama organic fertilizers production lines, Lines for the production of organic fertilizers for biogas, lines for the production of organic fertilizers based on humic acids and t. e. Welcome, Contact us for consultation and order.

FAQ about organic fertilizer from filled coal.

Get solutions for organic fertilizer production lines or equipment prices!