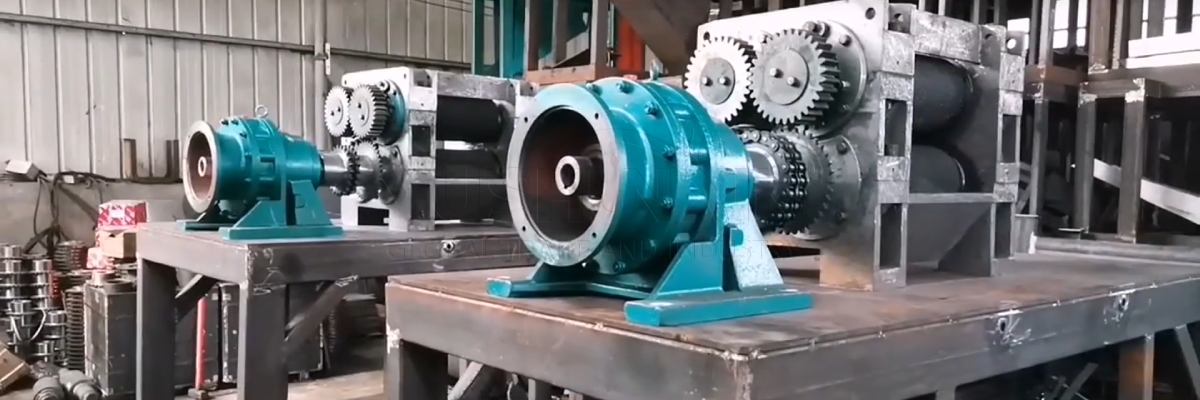

Roller granulator - popular granular equipment. It is widely used in the production sectors of granular fertilizers, such as organic fertilizers, Complex fertilizers, Ammonium sulfate, potassium fertilizers and so on.

Parameters of a two -rope granulator of organic fertilizers

- Power: 11 – 37 kW

- The size of the particles: 2 -10 mm

- The degree of granulation: 97% +

- Production capacity: 1 – 4 t/h.

- The size of the particles of raw materials before granulation: 10 oven.

- Moisture content of raw materials before granulation: 2% – 6%

- Equipment material: Carbon steel Q235 + 20CRMNTI or 4CR13

- Application: Powder compost, Phosphorus fertilizers, potassium fertilizers, Ammonium sulfate, Technical salt, NPK, Mineral fertilizers…

Our Roller granulator uses the process of dry granulation. Its unique extrusion design with two rollers allows you to process various powdered materials. And turn it into high -quality granules. The degree of granulation reaches more 97%. This equipment not only significantly increases the efficiency of production, but also provides uniformity and strength of particles. If your budget is limited, Two -wool granulator will be the perfect choice. Its price range is from 400 to 1000 dollars, What makes it extremely profitable. If you are interested in buying or want to learn more about the roller granulator, Please, Contact us. Our team will provide you with professional advice and services. Help you achieve your production goals.

As a roller granulator turns the powdered organic fertilizers you presented into granules?

Our roller extrusion granulator uses physical extrusion to produce organic fertilizers for you. Prepared materials enter the granulator through the boot port. After entering the equipment, the material is poured with a couple relatively rotating rolls. These videos usually have a special shape grooves. When the roller rotates, the material is pressed into these grooves, forming a sheet with particles. Then use a crushing rod, Located below, to break scaly particles. Get particles of organic fertilizers of the same size and homogeneous texture.

Contact us, To find out the price !What is the price of our granulator in the market?

Two-vault granulator SXDG-1T, for small production lines, Sold at a price from 400 to 600 US dollars. The production capacity is 1 t/h, which allows you to satisfy the needs of small -scale production. SXDG-1.5T is suitable for average production production, production capacity is usually about 1,5 t/h. Price of 600 to 800 dollars. SXDG-2T roller extrusion granulator at a price from 800 to 1000 US dollars. This model is designed for larger production and is suitable for large industries or enterprises, requiring effective production.

When choosing a suitable model, you can make comprehensive decisions, Based on their own needs for production facilities and business development plans for the future. Making a budget for a granulator, You also need to take into account the costs of transportation, installation and after -sales maintenance.

We recommend consulting in detail with supplier of the granulator Before buying. Make sure, that you have chosen equipment for roller granulation corresponds to your specific production needs.

Equipment parameters of a two -wool granulator

| Type | Power (kW) | The diameter of the particles (mm) | Performance range (t/h) | The size of the skin of the roller (mm) | Dimensional dimensions (mm) |

| SXDG-1T | 11 | 2-10 | 0.8-1.5 | Φ151*220 | 1430*750*1350 |

| SXDG-1.5T | 18,5 | 2-10 | 1-2 | Φ151*300 | 1560*800*1580 |

| SXDG-2T | 22 | 2-10 | 1.5-2.5 | Φ186*300 | 1560*800*1580 |

| SXDG-2T-Ⅱ | 15*2 | 2-10 | 1.2-1.5 | Φ186*300 | 2170*1000*1850 |

| SXDG-2.5T | 22 | 2-10 | 1-1.5 | Φ245*220 | 1700*1000*1670 |

| SXDG-2.5T-ⅱ | 18,5*2 | 2-10 | 1.3-1.8 | Φ242*220 | 2170*1000*1850 |

| SXDG-3T | 30 | 2-10 | 2.5-3.5 | Φ200*400 | 1960*980*1760 |

| SXDG-4T | 37 | 2-10 | 3-5 | Φ250*400 | 1960*980*1760 |

Roller granulator with front unloading VS two -valve granulator with side unloading

We have two roller granulators with different unloading modes. They are suitable for various layouts of industrial premises. Roller extrusion granulator with anterior unloading has a simple structure, it is easier to serve and clean it. It occupies a small space and is very suitable for production media with limited space. Besides, materials are unloaded directly in front, which makes the work more convenient and easy to observe and control.

The design of the roller granulator with side unloading provides effective unloading. Ideal for high -performance production lines. He can better adapt to specific processes, Especially there, where continuous production is required. This unloading method facilitates a direct connection with other equipment or conveyor ribbons. The overall efficiency and adaptability of the production line is increased. This method of unloading particles facilitates a direct connection with other equipment or conveyor ribbons. Increased the overall efficiency and adaptability of the production line.

What amenities gives you the use of a two -wool granulator in the production of granules of organic fertilizers?

Our roller granulator uses the process of dry granulation. It means, that you do not need the subsequent stage of drying during production, which greatly simplifies the process. Increases your performance. At the same time, this process can ensure the constancy of particle size and a guarantee of product quality. Besides, Our roller extrusion granulator itself is a low -energy equipment equipment. Can effectively reduce your production costs.

Besides, A great advantage is the flexibility of our equipment for granular. Simply adjusting the parameters of equipment, You can easily change the size and density of particles. To meet the needs of various customers. Such flexibility not only improves the market adaptability of your organic fertilizers. It also allows you to quickly respond to market changes and individual customer needs.

Generally, The use of our roller granulator can not only increase the efficiency of your production and product quality. This also gives you a more competitive market advantage. If you are interested in this equipment for granulation, Please, Contact us. We will be happy to provide you with additional support and services. Help your business to achieve more success in the market.

Contact us, To find out the price !

Roller material of the two -wool extrusion granulator, which you acquired, What we have chosen for you?

Extruse granulators should usually have high strength and wear resistance. This allows him to cope with long mechanical loads and friction. 20CRMO - widely used doped structural steel. It has good strength and wear resistance. Therefore, most of the rollers, which we make for you, made from this material.

The main alloying elements of steel 20CRMO are chromium (Cr) and molybdenum (Mo). The addition of these two elements can increase the prosperity and wear resistance of steel. After appropriate heat treatment (For example, Solking and vacation) 20CRMO can achieve high strength and shock viscosity. Ideal for granulation, where high strength and wear resistance is required.

Are the consumable parts of the roller granulator available in your region, which we provide you?

Bearings, seals, gears and other fast -intake parts can be purchased on the spot. We use universal bearings, seals and gears. Mainly, To guarantee, that you can easily purchase and replace it around the world. Reduce maintenance costs and reduce downtime time. Thereby increasing the efficiency of the production of organic fertilizers. We recommend that you store some consumables, used as a roller granulator, At your factory. Make sure, that you can replace it immediately, If necessary.

Four methods, which will help increase the efficiency of the production of your roller granulator.

- Firstly, optimize the process of preliminary processing of materials to improve the fluidity and formality of materials;

- Secondly, Depending on the characteristics of the material and production requirements, you should reasonably choose the diameter, width and speed of the roller;

- Third, introduction of modern automatic control systems to achieve accurate control and stable operation of equipment, as well as reducing breaks in production, caused by the human factor;

- Fourth, Regularly carry out maintenance and repair of equipment, to guarantee its good working condition.

How to ensure the quality of granules, produced by a roller granulator?

To ensure the quality of granules, you must first make sure, that the size of the particles, The humidity and composition of the material comply with the requirements of granular. Secondly, correctly adjust the pressure of the rollers, Speed and gap, to get the desired shape and density of particles. Besides, An important factor in improving the quality of pellets is regular maintenance of equipment to ensure its normal operation.

Get the price for this equipment !

Three common malfunctions of a two -vale granulator, How to eliminate them?

- Incorrect form of particles: This can be caused by an uneven gap between the rollers or the uneven distribution of the material. The gap between the videos can be adjusted, to make a gap uniformly. And check the feed device, To make sure, that the material is supplied evenly.

- Reducing performance: The reason may consist of too high moisture in the material, insufficient pressure of rolls or too low rotation speed, etc.. e. The humidity of the material can be appropriately reduced, you can increase the pressure of the rollers or increase the speed of rotation.

- The equipment vibrates greatly: This can be caused by loose equipment installation, unbalanced rollers or damaged bearings. It is necessary to check the installation base of the equipment and perform dynamic balancing rollers. If the bearing is damaged, Replace the bearing in a timely manner.

If you want to check the effect of granulizing your raw materials using a two -wool granulator. We invite you to send raw materials to our testing factory for testing. You can also personally bring raw materials to our factory and conduct tests yourself. Our factory has another Equipment for granulumI, from which you can choose. For example, disc granulator, Drum granulator, Granulator of new organic fertilizers and t. e. Besides, We can also provide you with compost equipment for fermentation and composting. Welcome, Contact us to buy a roller granulator.

FAQ about a two -wound granulator!

Get solutions for organic fertilizer production lines or equipment prices!