Solid-liquid separator machine play a key role in the production of organic fertilizers. Its main function is the effective separation of solid and liquid components of organic waste. Thereby improving the quality and efficiency of fertilizer production.

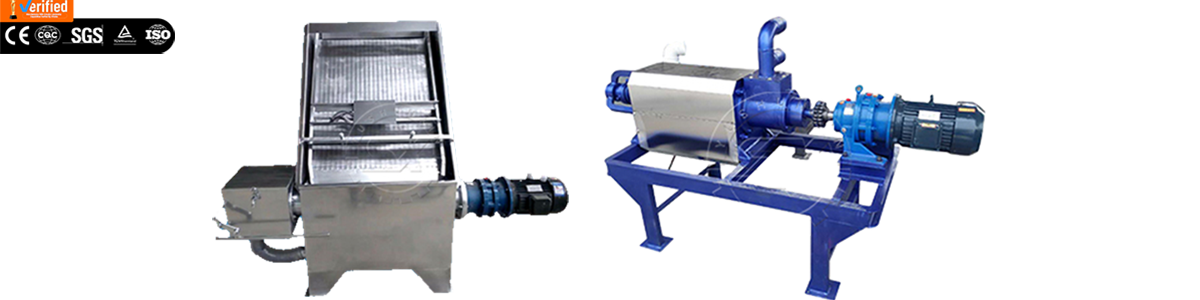

Spiral separator of liquid and solids

| Model | Performance (t/h) | Power (kW) | Dimensional dimensions (mm) |

| SXTS-180 | 10-15 | 4 | 1850*650*1150 |

| SXTS-230 | 15-20 | 5,5 | 1850*800*1150 |

The separator of the solid and liquid phase with inclined sieve

| Model | Performance (t/h) | Power (kW) | Dimensional dimensions (mm) |

| SXTSX-800 | 15-20 | 4 | 1700*1500*1300 |

| SXTSX-1200 | 30-40 | 5,5 | 2200*1500*1700 |

This can effectively reduce the complexity of wastewater treatment and reduce environmental pollution during the production process. Our factory offers you spiral separators of solid and liquid phases and separators of solid and liquid phases with inclined sieve. It is easy to operate, has low maintenance costs, but has high efficiency of processing. Our separator of the solid and liquid phases is sold at a price from 300 to 2000 US dollars, which is extremely economically profitable. If you are interested in buying or want to know more information, Please, Contact us. We will provide you with professional services and offers.

How much does it cost to buy one of our separators of a solid and liquid phase?

Our separator of the solid and liquid phases is sold at a price from 300 to 2000 US dollars. Made of high -quality materials, providing reliability and long service life of the device. For responsible components, we use stainless steel or high -strength alloys. This not only increases corrosion resistance, but also increases the stability of equipment in various working environments. If you need higher wear resistance for your use, We also offer you special materials.

Each separator of liquid and solids before sending from the plant passes a strict quality test. Make sure, that industry standards are observed or superior. If you need more detailed information about various models and materials or you want to know, Which model is best suited for your specific needs. Please, Feel free to contact our sales department. We will be happy to provide you with more professional advice and services. We will help you choose the one, which is suitable for you, and build long -term relationships.

We provide you with two separators of a solid and liquid phase! – A spiral separator of a solid and liquid phase and a separator of a solid and liquid phase with an inclined sieve.

Our plant has for you the two most popular highly effective separators of solid and liquid phases. This: A spiral separator of a solid and liquid phase and a separator of a solid and liquid phase with an inclined sieve. These two devices were carefully developed by us and have unique technical characteristics. It can provide the best effect of separation of solid and liquid phases in various use of.

Contact us, To find out the price !Spiral separator of liquid and solids

Our spiral separators of the solid and liquid phases are made of high -quality stainless steel and other corrosion -resistant materials. Make sure, that the equipment will be able to work steadily for you in various acidic and alkaline media for a long time. The internal rowing screw is treated with special processing and has high wear resistance. Thereby extending the service life. Our equipment for the separation of the solid and liquid phases not only strives for perfection in the choice of materials. We also strive for perfection in design and production. Provides you with maximum performance and reliability.

We use the technology of a spiral propeller to separate solids and liquids for you. This technology has effective separation capabilities. It allows you to quickly and effectively separate solids from liquids. Great characteristics even when cleaning wastewater with high concentration and viscosity. Secondly, We supply you with a modern control system. Simplify the operation process for yourself and reduce manual intervention. Significantly increase production efficiency.

| Model | Performance (t/h) | Power (kW) | Dimensional dimensions (mm) |

| SXTS-180 | 10-15 | 4 | 1850*650*1150 |

| SXTS-230 | 15-20 | 5,5 | 1850*800*1150 |

The separator of the solid and liquid phase with inclined sieve

Our separators of the solid and liquid phases with inclined sieve are made for you from all -resistant alloys and high -strength polymeric materials. The case is durable and is designed for prolonged use in harsh conditions. Suitable for industrial occasions, requiring prolonged and efficient operation. Its compact structure not only facilitates the installation and integration, but also effectively saves space. No matter, whether you are building a new project or upgrading existing equipment. Our separators of the solid and liquid phases can provide excellent performance.

The design of the inclined sieve allows you to effectively process various liquid waste, containing suspended substances. Such as wastewater of the food industry, lightening juices and t. e. Provide you with high efficiency of separation of solid and liquid phases. Besides, Our equipment for separating the solid and liquid phases consumes little energy during operation. Helps you to save operational costs and at the same time reduce environmental impact. The screen design simplifies cleaning and replacement, Reducing downtime. Make sure, that equipment can effectively perform work on separation for you.

| Model | Performance (t/h) | Power (kW) | Dimensional dimensions (mm) |

| SXTSX-800 | 15-20 | 4 | 1700*1500*1300 |

| SXTSX-1200 | 30-40 | 5,5 | 2200*1500*1700 |

How to choose between these two devices of the separation of the solid and liquid phases that, which is right for you?

Choose one, which best meets your needs: Spiral separators of the solid and liquid phases and separators of the solid and liquid phases with inclined sieve. You will have to get acquainted with both devices deeper. Then take the decision, Based on the needs of your specific application and operating environment. We summed up the following aspects for you, which you need to consider. On their basis, you can make your choice!

- Characteristics of the material. If the material, with whom you need to work, has a high content of solid particles or high viscosity, The spiral type may be more suitable. Against, If you are dealing with low -free liquids, An inclined sieve may turn out to be more economical.

- Requirements for processing power. Select suitable equipment for separation of the solid and liquid phases in accordance with your daily processing. The performance of our firm particle and fluid separator with inclined sieve will be more and reached 40 m³.

- Economic forces. Consider the initial investment and long -term operating costs. If your budget is limited and material conditions are suitable, The spiral separator of the solid and liquid phases may turn out to be a more economical choice.

- Space restrictions. Consider the installation and location of the equipment. Make sure, that the equipment you have chosen will be installed and will work uninterruptedly.

Based on the above factors, You can choose the most suitable equipment for separating the solid and liquid phases in accordance with your real needs. Achievement of effective and stable production operations. If you need additional recommendations or tips. We are pleased to provide you professional assistance. We will help you purchase a fiber and solid separator, which best corresponds to your needs.

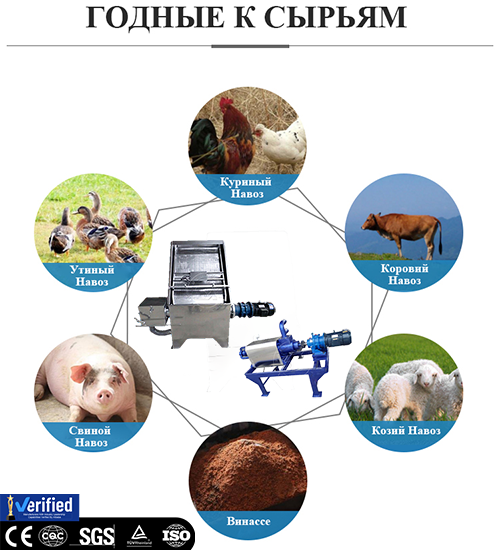

In which sectors our separator of liquid and solids is suitable for your use?

Buy our separator with a solid and liquid phase. You can not only satisfy your specific needs for processing, but also ensure economical work and compliance with environmental requirements. This can help you achieve an effective and reliable separation of solid and liquid phases. Below are scripts, which you can use after buying our separator solid and liquid phases.

Livestock: Widely used to separate the solid and liquid phases from the litter of livestock and poultry, such as a pig, Cows, hen, ducks, etc.. e. This can effectively reduce the water content in feces. Ensure convenience for subsequent compost processing.

- Livestock: Widely used to separate the solid and liquid phases from the litter of livestock and poultry, such as a pig, Cows, hen, ducks, etc.. e. This can effectively reduce the water content in feces. Ensure convenience for subsequent compost processing.

- Food industry: It can be used to compare squeezes, Separation of wine grains and t. e. In the process of squeezing fruits and vegetables.

- Environmentally friendly processing: can be used to dehydrate sediment on treatment facilities. Reduce the cost of recycling.

- Pharmaceutical and chemical industry: It is used for rough filtering of solid -firing mixtures and dehydration of drilling solutions.

- Textile printing and dyeing industry: used to separate fibers and solid particles in wastewater.

What methods can help you optimize the effectiveness of your firm and liquid phase separator?

The first step is to select a firm and liquid phase separator, Based on the properties of materials, with whom you work. The choice of a suitable model and technical characteristics is your first step to optimizing production efficiency. Pay attention to the technical parameters of the equipment: such as processing performance, The effectiveness of separation, energy consumption, etc.. e. Select a more effective separator of fluid and solids, which better corresponds to your needs.

The second step is the optimization of working parameters. Adjust such parameters, like rotation speed and pressure, In accordance with the characteristics of the material and separation requirements. For example, The speed of the screw, The screen of the screen, supply pressure and t. e. To achieve the best separation effect. At the same time, the feed rate is controlled, to ensure uniform and stable feed. Avoid overload or underloading.

Finally, You need to remove large impurities and solid particles from the material before entering the separator. To avoid damage to equipment. It is necessary to clean the device immediately after each use. Especially part of the spiral and screen. In order to avoid clogging with the remains of the material.

Precautions when using the separator solid and liquid phases, which will help you maximize the productivity of the separator of the liquid and solids.

For that, so that you maximize the productivity of the separator of the solid and liquid phase. As well as ensuring efficient operation and extending the service life of equipment. Here are some things, which should be paid attention to when using it. We hope to help you more effectively use our equipment for separation of solid and liquid phases.

Firstly, Your staff should be professionally trained and familiar with the instructions for the operation of equipment and safe operation procedures. And during the operation of the equipment it is strictly forbidden to put hands or tools into the equipment. To avoid random injuries. Install the device in a stable, dry, well ventilated. This will help you avoid the influence of environmental factors on the normal operation of the equipment. It is also necessary to take into account the system of drainage and sludge of the unit. To guarantee, that separated fluids and solids can be unloaded smoothly.

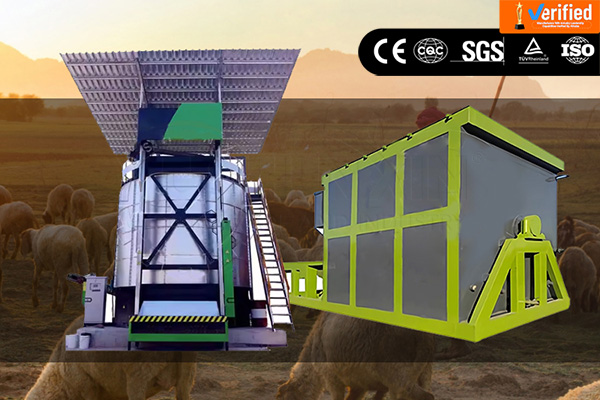

Shunxin is your best partner in the production of organic fertilizers!

IN compost production process at the preliminary processing stage a fluid and solid separator is often used. It allows you to effectively separate and remove excess liquid components and increase the content of solids in compost raw materials. This step not only optimizes the effectiveness of the subsequent process of composting. It also significantly improves the quality of the final product. We not only supply high -quality separators of the solid and liquid phases, but also provide you with a series of professional equipment for composting organic fertilizers And Equipment for granular. Help you build full and effective Organic fertilizer production line.

If you are interested in our firm and liquid phase separator, equipment for composting, equipment for granulum or other related products. Please, Feel free to contact us. We will provide you with professional consulting services and individual solutions. Satisfy your production needs. If you have time and plans, You can come to our factory and make a purchase on the spot.

Get solutions for organic fertilizer production lines or equipment prices!