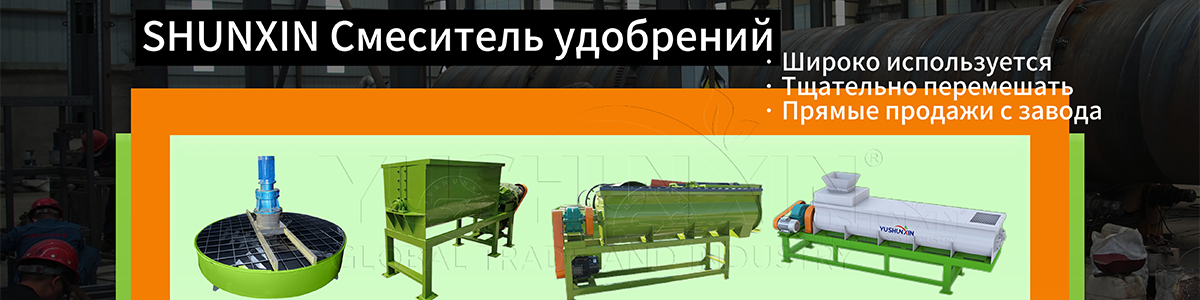

An effective fertilizer mixer is the main equipment, ensuring the uninterrupted course of the process of fertilizer production. Fertilizer mixer provides a more uniform distribution of fertilizer ingredients due to uniform mixing of various raw materials. Thereby improving the quality of your ready -made fertilizers and increasing your competitiveness in the market. We offer many types of mixers for fertilizers. Including horizontal mixers, disk mixers, Twarge horizontal mixers and one -acting mixers.. Satisfy the needs of your production line of various sizes and needs. Whether it is a small or middle farm or a large agricultural enterprise, Our equipment can provide you with effective and reliable solutions. Contact us, To purchase a fertilizer mixer, corresponding to your needs in the production of fertilizers.

Get an individual solution !Four mixers for organic fertilizers, which will help you produce high -quality organic fertilizers!

Horizontal mixer

Fertilizer horizontal mixer is highly effective mixing equipment, which is suitable for mixing various powdered and granular materials. Design features include horizontally located mixing shaft and specially designed blades or spiral tapes. He can make the materials completely turn over, convex and move in the mixing process, which allows you to achieve quick and uniform mixing. The device is usually driven by an electric motor and simply in operation. The case is made of high -quality steel with good wear resistance and corrosion resistance. Provide a long service life of the equipment and is suitable for various production environments. Due to its compact design, the mixer is ideal for small and medium -sized manufacturing enterprises.

Contact us, To find out the price !

| Model | SXHIP-7015 | Sxew-9015 | SCAB-1630 |

| Dimensional dimensions(mm) | 2350*1200*1000 | 2550*1500*1000 | 3950*1720*2100 |

| Engine power(kW) | 7,5 | 11 | 22 |

| Reducer model | ZQ350-23,34 | ZQ350-23,34 | ZQ500-48,57 |

| Mixing speed(rpm) | 46 | 39 | 21 |

| The thickness of the main body(mm) | 4 | 4 | 10 |

| Mixing productivity(t/h) | 2-3 | 3-5 | 10-15 |

Disk mixer

The main design of the disk mixer includes a horizontally located disk and vertically located mixing teeth. The disk rotates under the action of the engine, Forcing the materials continuously roll and rub on the disk, thereby achieving uniform mixing. It has high wear resistance and corrosion resistance, and also has advantages in processing materials with higher viscosity or larger particles. And the discount mixer of fertilizers is usually placed above the granulator, which allows you to save a place. At the same time, mixed materials can directly enter the granulator for further processing, which reduces time and energy consumption for the transportation of materials and increases the efficiency of production. Suitable for the use of small and medium -sized enterprises.

| Model | SXPJ-1600 | SXPJ-1800 | SXPJ-2000 | SXPJ-2200 | SXPJ-3000 |

| Dimensional dimensions(mm) | 1600*1600*1800 | 1800*1800*1800 | 2000*2000*1800 | 2200*2200*1850 | 3000*3000*2000 |

| The height of the edge of the disk (mm) | 400 | 400 | 400 | 400 | 400 |

| Disk diameter (mm) | 1600 | 1800 | 2000 | 2200 | 3000 |

| The power of the engine I(kW) | 7,5 | 7,5 | 7,5 | 7,5 | 15 |

| Reducer model | BLD15-87 | BLD15-87 | BLD15-87 | BLD15-87 | XLD9-87 |

| Mixing speed(rpm) | 16 | 16 | 16 | 16 | 16 |

| The thickness of the main body(mm) | 5 | 5 | 5 | 5 | 5 |

| The thickness of the lower plate (mm) | 8 | 8 | 8 | 8 | 8 |

| Mixing productivity(t/h) | 2-4 | 3-5 | 4-6 | 6-8 | 8-12 |

Twarge horizontal mixer

Twarge horizontal mixers are equipped with two parallel mixing shafts. These shafts are equipped with blades or stirring blades, which allow you to achieve thorough mixing of materials through relative movement. This design allows you to quickly and evenly mix the materials, ensuring the receipt of a homogeneous and homogeneous mixture.

Thanks to the horizontal structure, the materials are completely mixed under the action of gravity, which reduces energy consumption. At the same time, a design with two ramparts also increases the effectiveness of mixing and reduces mixing time. Our double -glove horizontal mixer of fertilizers can be adjusted in accordance with various production needs, For example, change the mixing speed, mixing time and t. e. To adapt to various process requirements. At the same time, the maintenance and cleaning of equipment is relatively simple, which facilitates you production management.

Contact us, To find out the price !

| Model | SXSJ-0830 | SXSJ-1050 |

| Engine power(kW) | 11 | 22 |

| Reducer model | ZQ350-31,5 | ZQ350-31,5 |

| External diameter of the stirring blade (mm) | 450 | 650 |

| Mixing speed(rpm) | 35 | 35 |

| Dimensional dimensions(mm) | 3700*800*750 | 6200*1300*1200 |

Continuous

Continuous mixers are widely used in production processes, requiring continuous mixing of materials. The equipment consists of a horizontal shaft and a number of mixing blades, installed on the shaft. Despite, that the design is single -axis, A good mixing effect is still achieved due to the carefully designed blade structure. In the production process, you can ensure the continuous supply and unloading of materials, as well as continuous mixing of materials. This design reduces the time of stay of materials in the machine and increases the efficiency of production. Suitable for continuous large -scale production. Moreover, His stable work makes him very suitable for production lines, requiring stable production. If you need this equipment, Contact us to get detailed information.

What are the advantages of our fertilizer mixer?

Durable material: made of high -quality stainless steel with excellent corrosion resistance. Suitable for processing various types of fertilizers. A strong design allows it to withstand long periods of intensive operation.

Effective production: It has great processing opportunities to increase production efficiency. Compared to traditional mixing equipment, the mixing speed is higher. Significantly reduced the production time of each batch.

Optimized design: Mixing blades are specially designed and optimized to significantly increase the effectiveness of mixing and reduce the dead angle of mixing. The modular design facilitates the disassembly and cleaning of equipment.

Flexible application: the possibility of flexible work with various types of fertilizers, Included granular, organic and chemical fertilizers. Respond to your various needs. Mixing parameters can also be flexible in accordance with various production processes and formulas.

Contact us to buy!

What after -sales service for a fertilizer mixer can you provide you Shunxin?

- Warranty service: The equipment is provided with a guarantee for one year from the date of purchase. During this period, If the malfunction is caused by the quality of the equipment itself, We will provide free repair services.

- Technical support: Our professional team is always ready to provide you with technical support and consulting services. Whether it is the equipment operating manual, Elimination of malfunctions or daily maintenance, You can contact us by phone or email.

- Training services: We offer you training courses for the operation and maintenance of equipment. Make sure, that your team has the skills of using and basic equipment maintenance.

- Supply of spare parts: We supply original spare parts to ensure stable equipment. And support quick delivery to satisfy your urgent needs.

If you are looking for an effective and reliable fertilizer mixer or you need a full structure production line, including Equipment for composting, crushing, granulation and other equipment, Please, Contact us. Our expert team will provide professional advice and individual solutions, taking into account your specific needs. We help you achieve higher production efficiency and improve product quality. We will be happy to cooperate with you for the joint development of your business for the production of fertilizers!

Get solutions for organic fertilizer production lines or equipment prices!