Do you want to enter the organic fertilizer market?, how to choose a suitable production line? This is a tough choice for investors., which have just entered the organic fertilizer market. According to our many years of experience, it is an ideal choice for investors, just entered the industry, — build a production line for granular organic fertilizer with annual productivity 30 000 ton. This production capacity allows you to meet the needs of small and medium-sized markets, effectively controlling investment costs and operational risks. Has good market adaptation and development potential. If you are interested organic fertilizer production line power 30 000 ton, contact us for consultation and purchase. We will provide you with professional solutions and comprehensive service support..

Get an individual solution !

My budget is limited. Which granulation line is right for me and what is its cost??

For clients with a limited budget and a desire to quickly recoup their investment, Twin roll extrusion granulation line is a good choice. The main equipment of this line includes a composter, raw material shredder, mixer, twin roll extrusion granulator, sifter, packaging machine and auxiliary conveyor equipment. The two-roll granulation line is characterized by a simple technological process, low investment in equipment and comparatively low operating and maintenance costs.

Our double roller granular organic fertilizer line 30 000 t/year has a total investment cost of approx. 70 000–100 000 US dollars (specific costs vary depending on equipment configuration and degree of automation). This is the preferred option for many startups. If you need a detailed hardware configuration list or quote, Please, Contact us!

My budget is approx. 150 000 US dollars, and I want to produce pure organic fertilizer. Which granular organic fertilizer production line is right for me?? How much does it cost?

Within your budget 150 000 dollars, we strongly recommend that you choose the organic fertilizer granule production line with agitator tine granulation. Granulator with agitator particularly suitable for the production of pure organic fertilizers. Has high adaptability to raw materials, high granulation rate and good granule quality. The whole production line mainly includes compost fermentation, turning over, crushing, granulation, drying, cooling, sifting and packaging.

Investment in equipment for annual productivity 30 000 tons of granular organic fertilizers usually range from 120 000 to 150 000 US dollars, which suits your budget. If you already have a plant, budget in the amount 150 000 US dollars will be enough to cover the cost of equipment and some commissioning work. This is a cost-effective option. If you need detailed information about the technological process, equipment parameters, list of equipment, prices and other information, Contact us!

I want to produce organic and inorganic fertilizers. Which granulation line is right for me?? How much does it cost?

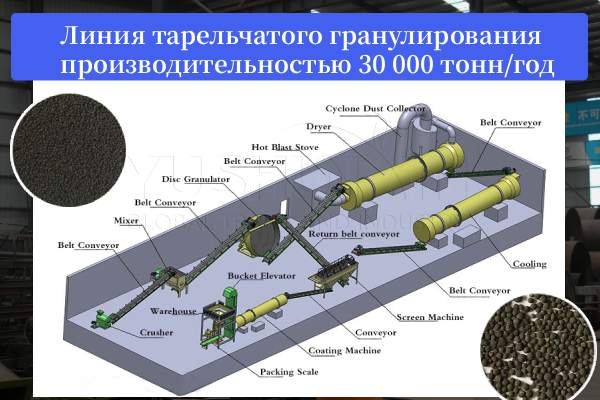

If you want to produce as organic, and inorganic fertilizers (For example, complex fertilizers or mixed organic-inorganic fertilizers), disc granulation line is an excellent option. Disc granulator It has such advantages, how highly adaptable, ease of operation and ease of maintenance. It can process various raw materials (including organic, inorganic and mixtures thereof) and produce round and uniform particles.

Purchasing cost of our plant's plate granulation line with annual production capacity 30 000 tons is from 150 000 to 200 000 US dollars. It covers all stages, including raw material processing, granulation, drying, cooling, sifting and packaging. If you are investing for the first time, we recommend choosing a configuration with a moderate degree of automation. This will not only satisfy market demand, but will also contribute to future expansion and modernization. If you need a detailed list of equipment, process flow diagram or plant layout samples, Contact us.

How to Scientifically Select Granular Organic Fertilizer Production Line Capacity 30 000 ton, which is suitable for you?

Choosing the right organic fertilizer pellet production line is critical to the profitability and sustainability of your project. Select appropriate manufacturing processes and equipment based on raw material types and process requirements, taking into account both the degree of automation, as well as efficiency. Also choose a manufacturer with proven capabilities and excellent after-sales service. Shunxin company has more than 20 years of production experience. If you have any questions or need professional advice when choosing and building a production line, Please, Contact us. We'll be happy to help.

How long will it take, to recoup the investment costs of our organic fertilizer granule production line with a capacity of 30 000 tons per year?

As an example, let's take a plate granulation line with a capacity of 30 000 tons worth 170 000 US dollars. Based on the current market situation, we counted, that the total cost of other production costs is approx. 22 US/ton. The current market price of organic fertilizer granules is approx. 225 US dollars per ton. This corresponds to a gross profit per ton of approximately 203 US dollars. Provided that production is fully loaded, all investment costs can be recouped within 4–6 months after the construction of the plant. In six months you can start making a profit. The return on investment is quite impressive, and the project is highly profitable. Contact us for detailed information on equipment acquisition and project cooperation!

Get solutions for production lines !What should you pay attention to when choosing a high quality organic fertilizer granule production line manufacturer??

- Manufacturer qualifications and use cases: choose vendors with real use cases and strong capabilities R&D.

- Focus on after-sales service: prompt response to equipment malfunctions and comprehensive warranty service.

- Personalized service: We can adapt production plans based on raw material characteristics and production capacity requirements.

- Economic efficiency of equipment, energy saving and environmental protection: Priority should be given to equipment with low energy consumption and a high degree of automation.

If you require a detailed quotation for a granular organic fertilizer production line with a capacity of 30 000 tons or individual technological solution, Contact us. We will provide you with individual technical support and consulting services. Help launch your project for the production of organic fertilizers into production with high quality and reduce investment risks.

Get solutions for organic fertilizer production lines or equipment prices!