Groove type compost turner - This is professional equipment, used to process organic waste and production compost. Its main function is to contribute to the rapid decomposition and decomposition of organic waste by means of mechanical turning and ventilation. This produces high -quality organic fertilizers for you.

PAZ parameters type of compost in a turning steam machine(You can configure)

- Model: SXCF-2500 – SXCF-6000

- Production capacity:10-20t/h

- The depth of the coup: 0,8 – 1,8 m

- The width of the rotation of the compost: 3 – 30 m

- Unloading speed: 100 (m)

- Working speed: 50 (m)

- Material of the beam: Q235

- Corresponding power:18,5 kW

- Applicable materials:Livestock manure, Il and garbage, filter slotting sugar factory, Slag Kek, straw sawdust and other organic waste.

Introduction of a groove type of compost in a lathe Enzymes

- Type of compost groove, a current machine is often called compost orbital enuments, compost caterpillar beads, turning machines, etc.. Professional compost equipment for the processing of organic waste and the production of compost.

- It can be used to ferment the cattle and poultry, Shlama, filter mud of sugar factory, the remnants of Kek, straw sawdust and other organic waste.

- This machine is widely used in fermentation operations and moisture removal in factories for the production of organic fertilizers, Complex fertilizers production plants, Plants for the production of sediment and waste, Garden fields, factories for the production of biper and t. e.

- Our collar of compost with a groove can have a flight from 3 to 30 meters and height from 0,8 to 1,8 meter.

- We have models with double and half -shorts to meet the various needs of our customers. The design with two tanks is suitable for users, which requires large -scale processing and rapid revolving compost. The semi -terminal type is more suitable for small and medium operations.

- Offered by us the groove of the type of compost lathe available in two versions: with a hydraulic rise and with a mechanical rise. To satisfy operational habits and real needs of various users. If the equipment requires frequent height adjustment, We recommend choosing a hydraulic lifting system. To increase the efficiency of work and comfort of operation. In cases with a limited budget and small requirements for raising a mechanical rise is a practical and economical choice.

The collar of compost with the groove is the main technical

| Model | Engine power (kW) | Moving the engine(kW) | Lifting engine(kW) | Working speed (m) | Unloading speed (m) | The width of the turn (mm) | The maximum turn height (mm) |

| SXCF-2500 | 15 | 1,5 | 0,75 | 50 | 100 | 2500 | 1000 |

| SXCF-3000 | 18,5 | 1,5 | 0,75 | 50 | 100 | 3000 | 1200 |

| SXCF-4000 | 15*2 | 1,5 | 0,75 | 50 | 100 | 4000 | 1200 |

| SXCF-5000 | 18,5*2 | 1,5 | 0,75 | 50 | 100 | 5000 | 1500 |

| SXCF-6000 | 22 | 1,5 | 0,75 | 50 | 100 | 6000 | 1500 |

| SXCF-8000 | 22*2 | 1,5 | 0,75 | 50 | 100 | 8000 | 1800 |

Technical characteristics – Milot -shaped stumber of compost

Automatic control:

Centralized control cabinet, equipped with equipment, can implement the functions of manual or automatic control. You can choose a coup mode by time or at a fixed speed in accordance with your specific needs. Thereby increases the efficiency of work and labor costs are reduced. Ensures the stability and constancy of the composting process.

Wide applicability:

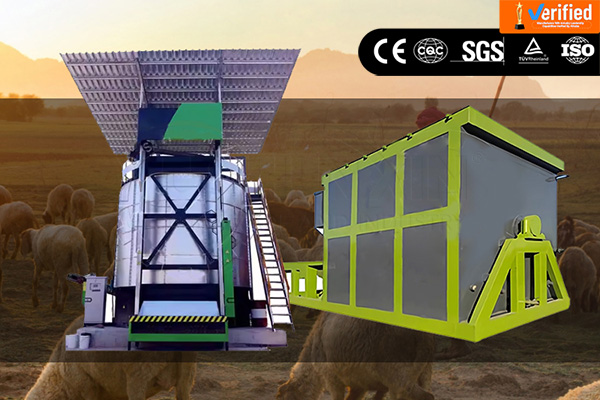

Equipment is specially designed for aerobic fermentation. It can be used in combination with solar enzymatic chambers, Armor reservoirs, mobile machines and t. e. We can provide you with flexible solutions for fermentation. Accelerate the decomposition of organic substances, thereby reducing the fermentation cycle.

Structural design:

Strong and durable design of the teeth of the mixer improves the possibility of decomposition and mixing of materials. This allows you to evenly mix and completely oxidize the stored materials, Improving the quality of fermentation. It also has high wear resistance, which ensures the stability of equipment with prolonged use.

Materials and design:

Equipment designs are usually made of corrosion -resistant materials. To cope with corrosion substances, formed in the process of composting. Extend your equipment service life. The constructive design is focused on stability and durability. Ensure stable operation of equipment in various environmental conditions.

Energy -saving design:

Due to the constant optimization of the energy system, our compost collar with the groove can reduce energy consumption as much as possible, ensuring the efficiency of work. Interacting with the automation system, The equipment can dynamically regulate power consumption depending on the load conditions. Save the operating costs.

How the compost collar with the groove works?

First, organic waste is placed in the fermentation tank, such as droplings and birds, straw And kitchen waste. Further, the raw materials are preliminarily mixed by means of mechanical devices. Make sure, that the materials are distributed evenly, to ensure uniform fermentation. After starting Devices of the storage rotor with a groove will move along this guide. A heap of materials is turned over by rotating mixing teeth. Increase ventilation and heat transfer of materials. Contribute to the growth of aerobic microorganisms and the rapid decomposition of organic substances.

During the fermentation process, turning can help you control the temperature and humidity of the compost to the optimal fermentation range. To speed up the decomposition. As the fermentation process continues, the volume and humidity of the heap gradually decrease. Use the collar of compost with a groove, to regularly turn over materials, to ensure complete fermentation. After a period of fermentation and maturation, materials, Completely composting process, Unloaded from the tank. Used as a fertilizer or subjected to further processing.

Get solutions for organic fertilizer production lines or equipment prices!