How to achieve daily production 100 tons of powdered organic fertilizers from manure, straw and other raw materials? Calculation is made at the rate of a 10-hour working day. Then 10 tons of powdered organic fertilizer - this is your time production need. Based on 300 working days a year, You can easily reach the annual production line in 30 000 tons of powdered organic fertilizer. For friends, who want to produce and process organic fertilizers. If you want to know about the process of fermentation of organic fertilizers, Planning the site, development of the program, cost and profit analysis, procedures, necessary for the construction of the plant, as well as other related information. You can send us an email for consultation.

Get an individual solution !

The main raw material for the production of powder organic fertilizer is manure and poultry. In case of harmless processing of livestock and poultry, aerobic fermentation in the strip is usually used. That is, general stagnation enzymation. During fermentation, wind and rain should be avoided. Long wind and rain will lead to a decrease in the content of organic substances. Therefore, before the fermentation, it is necessary to build a canopy, Protective from rain, and fold the fermentation vat. Then you can freely produce powder organic fertilizer. So, What seven steps will help you reach time production 10 tons of powdered organic fertilizer?

Get an individual solution and prices !

Correctly portray the raw materials.

The ratio of raw materials, necessary for production 10 tons of powdered organic fertilizer per hour, will vary depending on the specific type of raw materials and the targeted content of nutrients. Usually the ratio of raw materials per ton is: 500 kg of cow manure + 300 kg of pork manure + 200 kg of the remains of the fungus + 50 g fungus (cow manure and pork manure can also be replaced with other manure and bird manure) Auxiliary materials. What to do, if cattle and bird manure are too wet? You can add appropriate materials with a low moisture content, Such as straw, Rice husk, Burning flour and t. e in.. Reduce moisture content in fermented materials. In the process of ratio, attention should be paid to the optimization of the ratio of carbon and nitrogen. Usually, Ideal is the ratio of carbon and nitrogen from 25:1 to 30:1. This can effectively contribute to effective fermentation and decomposition of microorganisms.

Put the materials in long stripes.

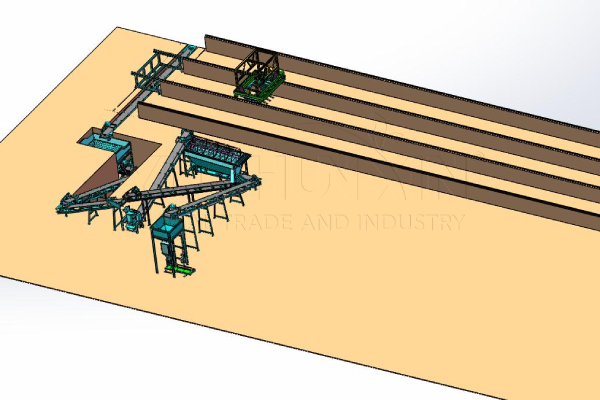

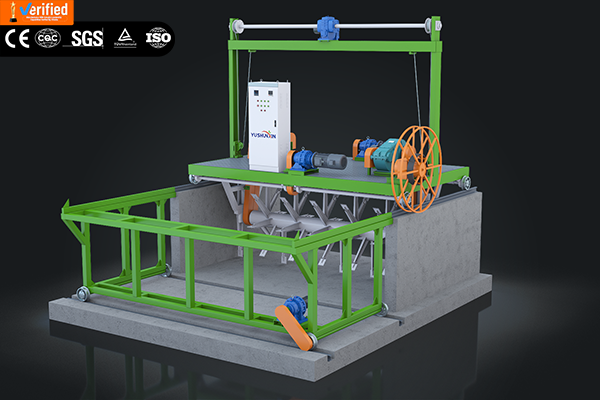

In accordance with the above ratio of raw materials, make a strip stack as necessary. The length of the stack is the strip stack is not limited. The width is about 2 meters, And the height is about 1 meter. When laying, the materials must be laid evenly a layer by a layer. Choose a suitable width of the manor of manure depending on the number of processed manure. The photo below shows our Lotco -type heapon, who is popular with customers. The height of the storage of compost can be adjusted, and the speed of the return of the layer of compost can be reduced.

Get an individual solution and prices !

Add fermentation bacteria.

Dilute bacteria and residue in the ratio 1:5. (The purpose of this is to dilute the bacteria and evenly distribute them. For example, 1 kg of bacteria can be mixed with 5 kg of wheat bran or powder of rice husks.) Usually, 1 kg of bacteria can enzyme 10-20 tons of feces and straw. If the quantity, at once, Big, You can use Twarge horizontal mixer For uniform mixing. Pour on the surface of the roll in accordance with the number of the roll.

Reversal and fermentation.

Use the bore of the compost with a tray and another Equipment for turning, To turn the bunch. After that, how the temperature rises above 55 ℃, Turn the bunch every 1-2 days. After fermentation at 55 ℃, for 10-15 days, the strip compost can be collected. (The purpose of turning the heap is to evaporate water, oxygen enters a heap, and the strain falls into a heap and is rapidly propagated and fermented)

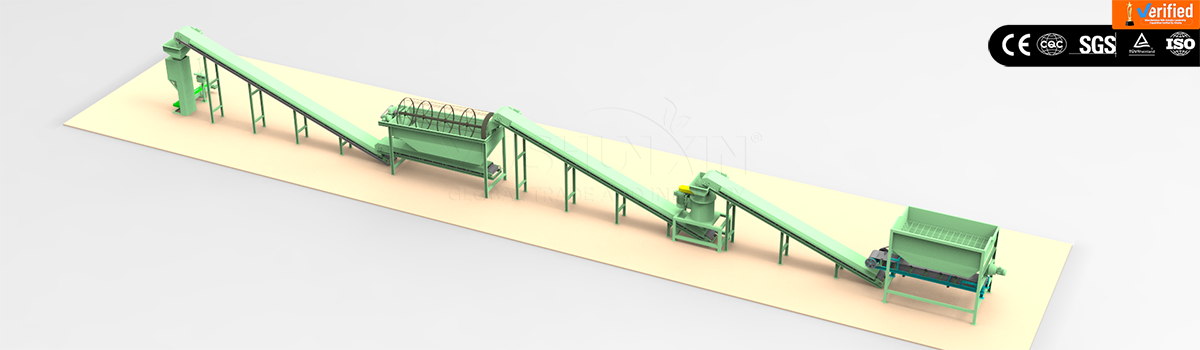

Crushing.

Enzymed materials cannot be sold directly as a product. This is due to that, that long -term storage will lead to agglomeration and other phenomena. At this time, the remaining bulk materials must be thinly chopped with the help crushers for materials of high humidity, to get powdered organic fertilizer.

Screening.

To improve the appearance, powder organic fertilizer is re -sifted. Only after receiving a homogeneous powder material can it be packaged. After sifting in a drum sorting machine, it becomes pure powdered organic fertilizer.

Package.

Powder organic fertilizer can be directly placed for storage and sold after packaging on automatic packaging weights.

Get an individual solution and prices !

After these 7 steps can be produced powdered organic fertilizer. Certainly, If you want to make powdered organic fertilizer, which meets the standards, You also need to determine the composition of the organic matter of fermented feces and straw fertilizers, and also add nitrogen content, phosphorus and potassium. At the same time, you need to adjust the proportion of auxiliary materials, Such as straw, To determine various formulas of the content of organic fertilizer. The whole set of equipment for the production line 10 tons of powdered organic fertilizer per hour has low investments. If you are interested in this, Please, Contact us. Our professional engineers will plan the site and develop solutions for your line for the production of organic fertilizers. You can also visit our завод SHUNXIN.

Get solutions for organic fertilizer production lines or equipment prices!