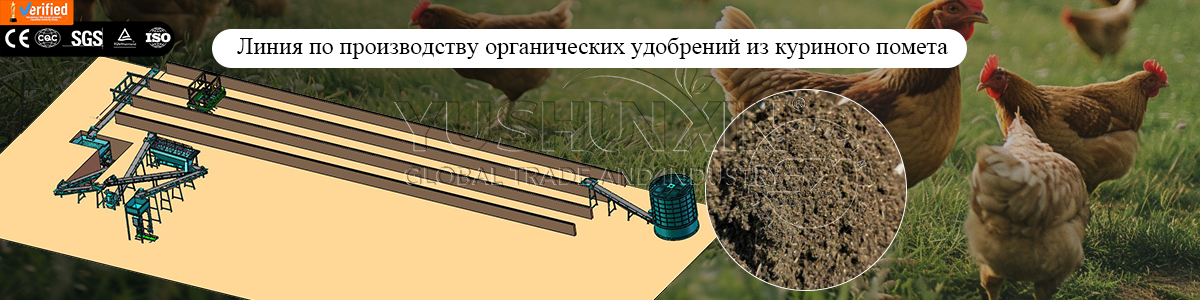

A large poultry farm in Kazakhstan plans process chicken label into organic fertilizer. Use chicken droppings as a resource and reduce the load on the environment on the farms. and open new sources of income. Therefore, we came to us for settings of the line for the production of fertilizers from chicken droppings by annual performance 5000 ton. Depending on the size of the site and the scale of the client’s production, we carefully designed for him the line for the production of powdered organic fertilizers. Including Armor reservoirs, Pamitan composters, Vertical crushers, Sifting cars for powders, packaging machines and other equipment. He can produce about 30 tons of organic fertilizers from chicken droppings for customers every day. The cost of equipment, included in the entire line for the production of organic fertilizers from chicken droppings, It is about 30 000 US dollars. If you have plans for the processing of manure, Contact us to obtain individual decisions.

Get an individual solution !

The specific situation of Kazakhstani customers. Provide you information for investment in the line for the production of organic fertilizers.

Our client in Kazakhstan runs a very large poultry farm. There are about 300 000 belt. These chickens can produce 37 tons of fresh chicken flow every day. For effective management of this huge amount of organic waste. The customer from Kazakhstan decided to build a small line for the production of organic fertilizers near the tribal farm. Used for the production of fertilizers from chicken droppings. To implement the use of resources and added the cost of manure. If you have a similar situation, Be it chicken litter, Pork manure, Korovy manure and t. e. You can consider the possibility of investing in a line for the production of organic fertilizers, to ensure the use of resources and value added.

Get an individual solution and prices !Kazakhstani client: Plan of procurement

Annual production volume: 5000 ton

Type of production line: powder production line

The cost of purchase: 30000 US dollars

Includes equipment: enzymatic tank, The composter of the trench type, Vertical crusher, sieve for powder, Packaging machine

What are the details of the line for the production of fertilizers from chicken droppings, which we have developed for customers in Kazakhstan?

The final product of the line for the production of organic fertilizers from chicken droppings, which we have developed for Kazakhstani clients, is a high -quality powder organic fertilizer. Available for customers in Kazakhstan for sale in adjacent regions. The following information is given about the line for the production of organic fertilizers from powder chicken droppings, which we have developed for customers in Kazakhstan.

Fermentation of chicken droppings

The first is primary fermentation. We provide customers in Kazakhstan Country for fermentation of chicken droppings with volume 50 m³. He can accommodate chicken droppings, produced by a poultry farm in one day. Fresh chicken droppings enters the fermentation tank through the bucket elevator for primary fermentation. This process lasts one day. In the fermentation reservoir, the temperature of the chicken litter will gradually increase and reach higher 60 Celsius degrees. Ensures the rapid decomposition of harmful pathogenic bacteria and parasites In the chicken litter, Significantly reducing the smell.

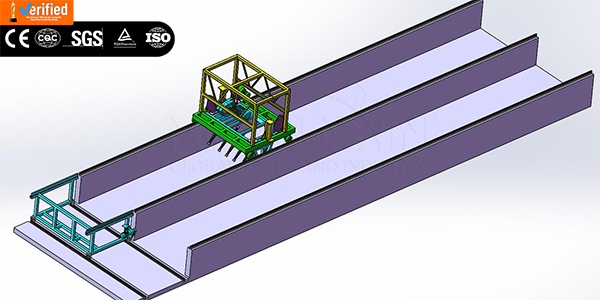

Materials after primary fermentation will be transported to the compost zone for secondary fermentation. To further improve the quality and maturity of organic fertilizers, we provide our customers with modern trim layouts. Depending on the volume of production of the customer, it is recommended to build three fermentation vats. Our equipment for turning compost can be used in several fermentation vats. With the help of a moved trolley in three fermentation vats, you can perform sufficient rotary work. Further improvement of the maturity of organic fertilizers.

Get the price for this equipment !

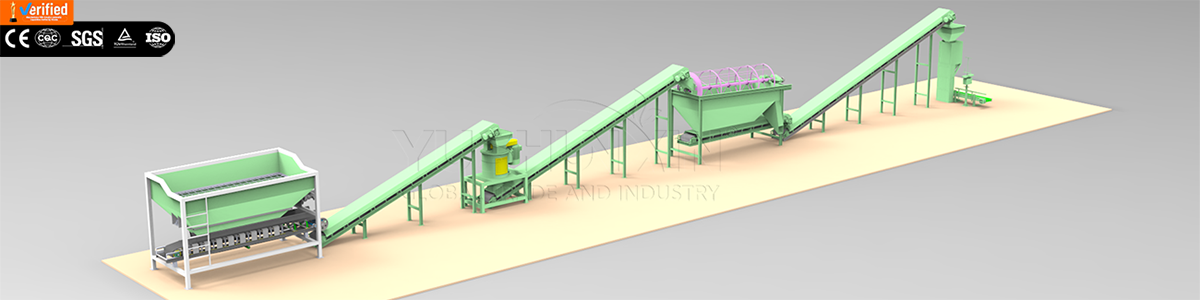

Processing compost from chicken droppings

Fully fermented and composite materials will be transported to the processing section of powder organic fertilizers. Here, the component material is additionally crushed and sifted. Ultimately, a homogeneous powder organic fertilizer is obtained. Then, on the packaging car, it is packaged in packages of various specifications. The production process of the entire production line is uninterrupted and effective. This not only saves production time, but also reduces costs. Maximize the effectiveness of the production of organic fertilizers from chicken droppings for customers in Kazakhstan.

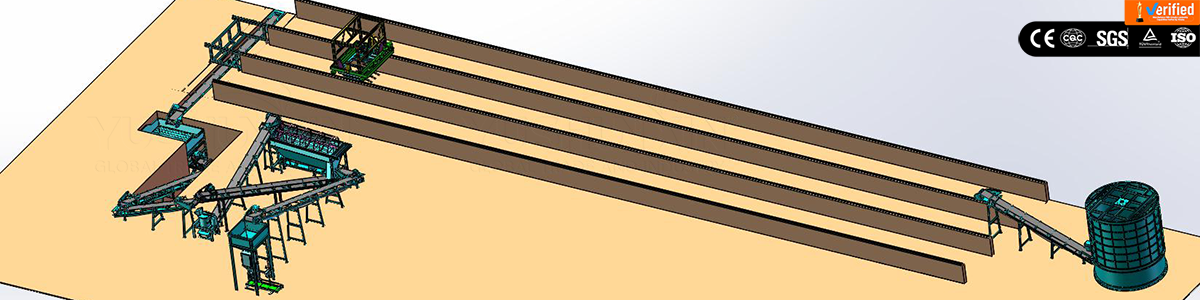

What are the scale and layout of the plant for the production of organic fertilizers from chicken droppings from a Kazakh customer?

The Kazakh customer plans to install a full production line behind the farm. The area is occupied by an area of about 1728 square meters (36m × 48m). In accordance with the customer’s production site, we carefully design the arrangement of equipment to increase the efficiency of work.

We installed the storage zone of raw materials on the left side of the fermentation vat. Dimensions 48x12m. There is enough space for the accumulation of fresh chicken droppings. Three fermentation vats occupy a total area of 12 × 40 m and are located in the center of the site. Provide an effective fermentation process.

In the opening for unloading the compost of the fermentation tanks, we designed for our customers a zone of unloading a size of 12 × 2 m. To facilitate the smooth transmission of materials. The enzyme tank is located in front of the boot opening. This arrangement allows the materials after primary fermentation to go directly to the fermentation vat for secondary fermentation. The process is simplified, And the time of transportation is reduced.

On the right side of the fermentation vigor we have placed the processing zone of powdered organic fertilizers and the stagnation zone of ready -made organic fertilizer from chicken droppings. This layout optimizes the effectiveness of the entire production line. This provides a smooth flow of materials from fermentation to final processing and storage. Thanks to such layouts, customers can achieve a higher efficiency of production and use of the space.

Contact us, To find out the price !Shunsin, Your best partner!

Line of fertilizers of chicken droppings has established myself well from the start of the launch. Clients praised its effective and stable work. If you also have plans invest in organic fertilizer production line. For example, organic fertilizer of pigs, organic fertilizer of cow manure and t. e. You can contact us, To get a suitable for you to a production line.

Get solutions for organic fertilizer production lines or equipment prices!