Brown coal as fertilizer is a solution, which we offer you, allows the fullest to use brown coal resources. Using advanced processing technologies and scientific methods. Organic substances and minerals in lignet are effectively released, forming a highly effective organic fertilizer. We offer a full range of solutions for fertilizers made of brown coal. Including the processing of raw materials, Production lines technology, Equipment configuration and operational technical guidance. Make sure, that every step can bring you the best results. Our professional team Develop a solution, your specific needs. Provide yourself maximum economic and environmental benefits when using lignite resources. To obtain more information, Please, Contact us.

Get an individual solution !

Why is lignite suitable for your fertilizer production?

Brown coal as fertilizer of raw materials for production, First of all, Thanks to its many advantages in terms of economy, the content of organic substances and nutrition. From an economic point of view, the production and processing of the lignite is inexpensive, And its reserves are very vast. The use of brown coal as a raw material for fertilizers can significantly reduce the total cost of the production of fertilizers. As for organic matter, lignite rich in humic acid, which can improve soil structure and microbial activity. Very well suited for use in organic farming. At the nutritional level, brown coal contains many minerals and trace elements and has the effect of prolonged release. It can continuously provide nutrients, necessary for the growth of agricultural crops. Transforming brown coal into fertilizers using scientific methods, You can effectively realize its advantages. If you are interested in this, Please, Contact us!

Get an individual solution and prices !

We will provide you with detailed information about the design of solutions for brown coal as a fertilizer.

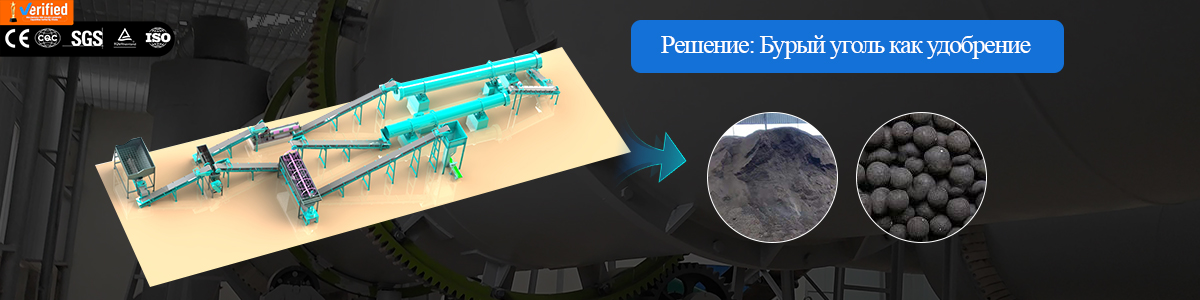

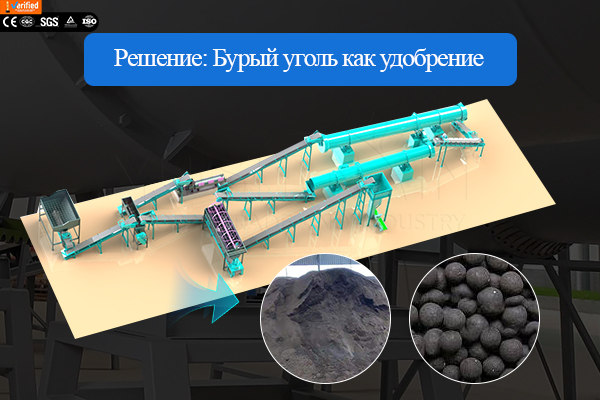

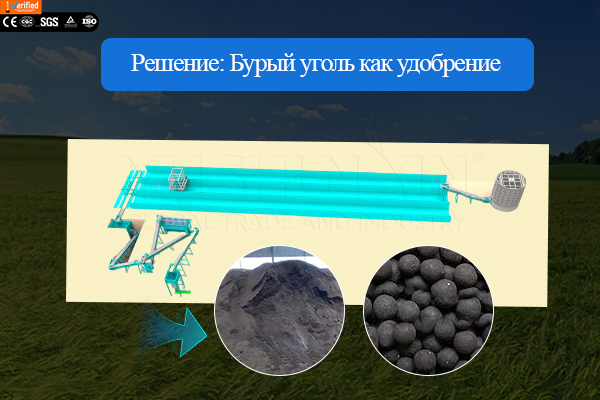

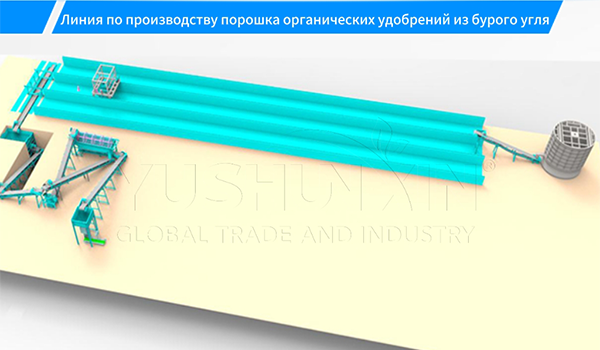

For the effective use of lignite for the production of fertilizers, we have developed a comprehensive solution. Covers several stages from the processing of raw materials to obtaining the final product. Provide effective, economical and environmentally friendly production processes. First you take high -quality lignite and subject it to physical processing. Crushed with a crusher and sifted by a sorting machine. Improve its reaction capacity. Then, During the phase of fermentation, The organic components of the lignite are converted into form, which is more easily absorbed by plants under the influence of microorganisms.

According to the recipe, Fermented Ligneen mixes with other ingredients to ensure a balanced balance of nutrients. Then mixed fertilizer granular. Improve the stability and applicability of fertilizers. Finally, Long -term storage and transportation of the product is ensured by drying and packaging. Thanks to this systematic solution, we strive to fully reveal the advantages of the lignite and provide you with an economically effective and environmentally friendly option for the production of fertilizers.

Get solutions for production lines !

What steps need to be taken to ferment brown coal in fertilizer?

The most important stage in the use of brown coal as fertilizer is fermentation. Brown coal is rich in humic acids, and fermentation can additionally release and transform these organic materials, Making them more affordable for plants. The process begins with the selection and grinding of high -quality lignite. Increase the surface area and increase the effectiveness of fermentation. Then, adjusting the humidity and pH, For microorganisms, a suitable environment for growth is created. Then a certain microbial flora is selected (bacteria, Fungi, yeast, etc.. e in.) for monoculation. These microorganisms are able to effectively decompose organic substances in coal brown, releasing humic acid and other beneficial components.

Get an individual solution and prices !

Throughout the fermentation process, it is necessary to carefully monitor the temperature, Humidity and ventilation. Maintain the optimal activity of microorganisms. After completion of fermentation, you can check the quality. Make sure, that the content of humic acid and other nutrients meets the expected standards. Due to this process of fermentation, humic acid and nutrients from lignite are easier for plants. thereby increasing its value as a fertilizer for soil or fertilizer. If you are interested in this and intend to invest in the production of bulky organic fertilizers, Contact us.

What equipment can we provide you with brown coal for fermentation as fertilizer?

Using the appropriate equipment in the process of lignite fermentation can increase the efficiency and quality of products. Depending on the specific scale of fermentation and technological requirements, the choice and configuration of equipment may vary. Here are some reference devices, which we provide you. If you have special requirements for equipment and processes, Contact us to obtain detailed information and prices.

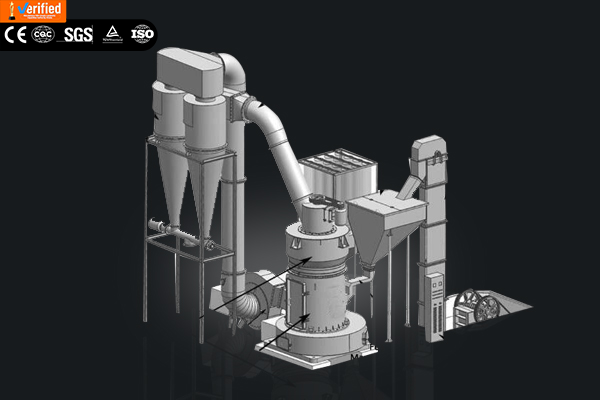

Raymond mill

Twarge horizontal mixer

- Raymond mill: This is a widely used grinding equipment. Used to grind lignite into smaller powder in order to increase its surface area. This helps to increase the effectiveness of contact between microorganisms and lignite in the process of fermentation, thereby accelerating the reaction of fermentation.

- Horizontal mixer: used for uniform mixing of lignial powder, additives and microorganisms. Uniform mixing helps to ensure a uniform fermentation process. And improve the sequence and quality of products.

- Armor reservoir: provides the controlled environment for the fermentation process. The possibility of temperature regulation, moisture and ventilation conditions. Make sure, that microorganisms are able to ferment in optimal conditions.

- Machine for turning the compost of the groove type: It is mainly used in the process of aerobic fermentation. Provide adequate oxidation and decomposition of fermented material by regular turning and aeration. This equipment helps to accelerate the process of fermentation and levels the temperature and humidity.

What humidity should be controlled during brown coal fermentation?

Humidity is a key parameter during brown coal fermentation. Because it directly affects the activity and effectiveness of microorganism enzyme. You can adjust the humidity level depending on the stage of enzyme:

Preliminary fermentation. At the stage of preparation for fermentation, it is usually necessary to bring the humidity of brown coal to the level, suitable for the growth of microorganisms. In general, humidity should be monitored in the range from 40% to 55%. This helps to guarantee, that microorganisms will be able to smoothly begin the process of fermentation.

During fermentation. During the active stage of fermentation, maintaining appropriate humidity is very important to ensure constant microbial activity and the effectiveness of enzyme. Usually humidity should be maintained from 50% to 60%. At this stage, it is necessary to regularly control the humidity and, if necessary, adjust it by adding water or ventilation.

Postfermentation. After the completion of fermentation, the humidity level can be reduced, to facilitate subsequent processing and storage. At this time, humidity can usually be controlled at the level from 30% to 40%. Ensure the stability of the product and facilitate subsequent processing.

It should be noted, that specific humidity control can vary depending on the specific requirements of the process and environmental conditions. Therefore, in real operation, appropriate adjustments should be made and optimized in accordance with the real conditions of fermentation.

How long does it take to enzyme lignite using our equipment?

Under normal circumstances, the time of fermentation, Brown coal required for use as a fertilizer, It is 2-4 weeks. The actual fermentation time may vary depending on the specific operating conditions, equipment performance and raw materials characteristics. To optimize the fermentation process, thorough monitoring and adjustment of several key work parameters is recommended. For example, temperature, Humidity and ventilation speed. Besides, The initial conditions of raw materials also affect the time of fermentation, such as particle size, chemical composition and t. e. Therefore, during the fermentation process, we recommend that we regularly check and measure. So that you can make adjustments in a timely manner. Such dynamic management helps reduce the time of fermentation and improve the quality and consistency of the final product. If you need it Buy equipment for composting and fermentation, Contact us.

Get solutions for production lines !

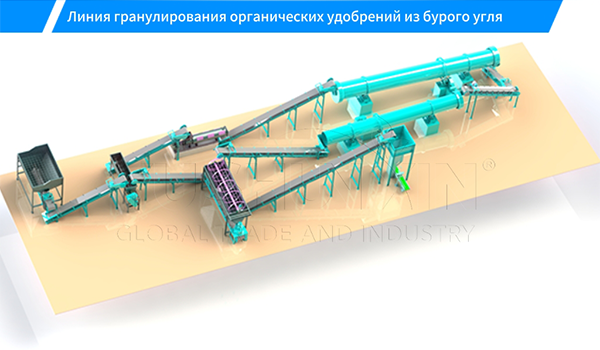

What is the usually used equipment for granulting of brilliant organic fertilizers we can provide you with?

Grauling is the process of turning an enzyme lignific material into granular fertilizer. Usually used equipment for granulation includes a disk granulator, Roller granulator, drum granulator and t. e. Disk granulator is suitable for small and medium -sized production, easy to operate and requires low maintenance costs. The drum granulator is suitable for large -scale production and has effective and continuous production capabilities. The resulting particles of the lignite are homogeneous and have high quality. The two -wool granulator is popular due to its compact design and high forming efficiency. It is especially suitable for the production of particles with high density and hardness.

Besides, We have another granulation equipment With various processes. They use the scientific granular process, To help you granulate lignite. When choosing the right equipment for granulation, such factors should be taken into account, as characteristics of the material, Exit and cost requirements. If you need to purchase equipment for granular coal, Please, Contact us, To find out the price.

Contact us, To find out the price !Shunxin manufacturer of equipment for organic fertilizers

In addition to decisions for brown coal as fertilizer, We also offer various types of equipment for the production of organic fertilizers and technical solutions. Including Guminic acid fertilizer production line, line for the production of organic fertilizers from chicken droppings and t. e. Our production lines are well designed to satisfy the needs of various types of production of organic fertilizers. Help you achieve the goals of effective and environmentally friendly production. To obtain more information, Please, Contact us.

Get solutions for organic fertilizer production lines or equipment prices!